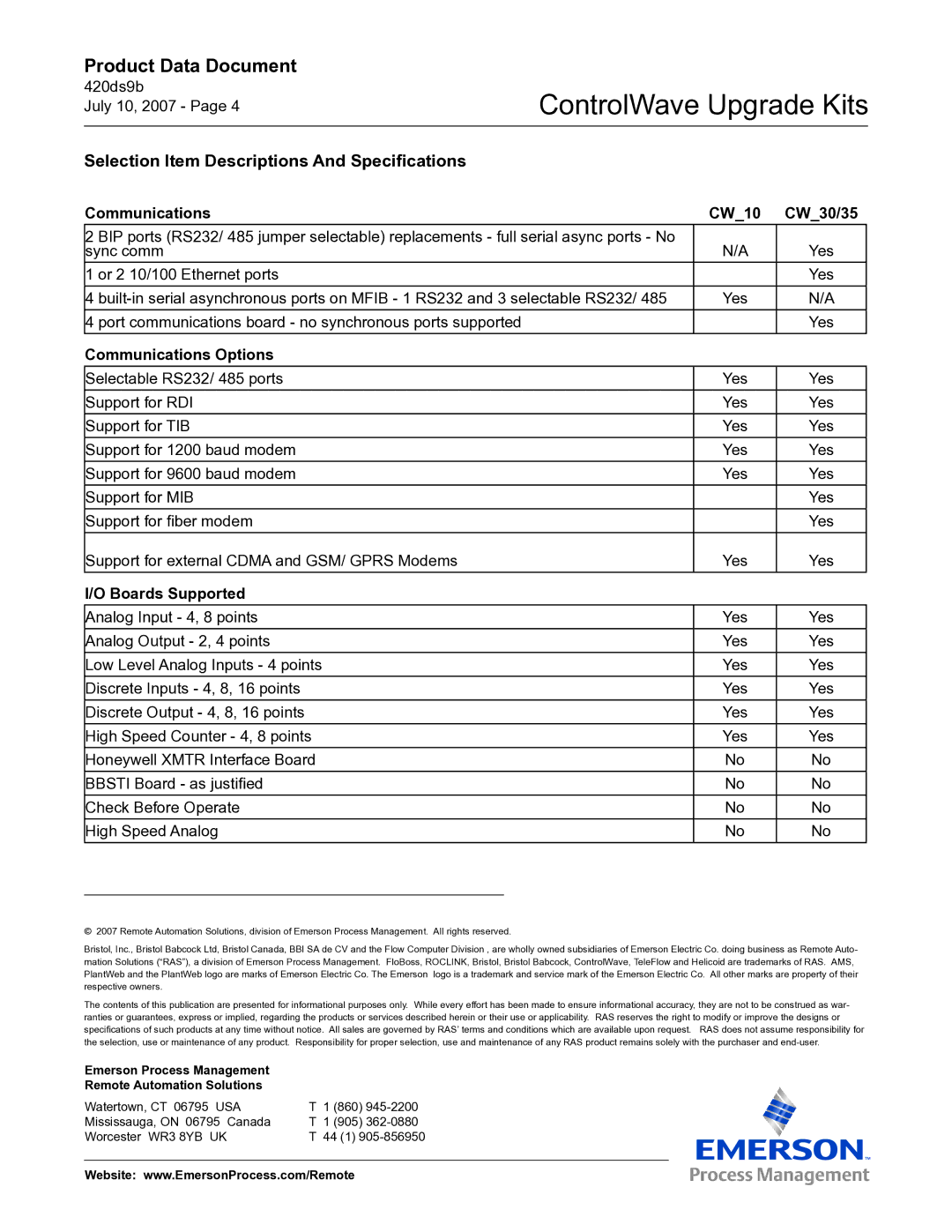

CW_10, CW_35, CW_31 specifications

Emerson Process Management is renowned for its innovative solutions in the field of automation and control systems. Among its extensive portfolio, the CW_31, CW_35, and CW_10 models stand out for their unique features and advanced technologies tailored for diverse industrial applications.The CW_31 is a compact and efficient control system designed for use in a variety of settings. Its main features include a user-friendly interface that allows operators to easily monitor and control processes. The CW_31 employs advanced loop control algorithms, ensuring optimal performance under varying conditions. This model is known for its robustness and reliability, making it suitable for industries ranging from manufacturing to oil and gas. Additionally, it supports multiple communication protocols, ensuring compatibility with a wide range of field devices and systems.

The CW_35 model, on the other hand, is designed for applications that require high availability and performance. One of its standout characteristics is its redundant architecture, which enhances system reliability and minimizes downtime. The CW_35 is equipped with cutting-edge cybersecurity measures, safeguarding critical operations against potential threats. This model also features enhanced data analytics capabilities that allow for real-time monitoring and predictive maintenance, thus optimizing operational efficiency. Its scalability makes it particularly appealing for large-scale industrial applications, providing organizations with the flexibility to expand their systems as needed.

Lastly, the CW_10 is a highly versatile control system ideal for smaller operations or applications with specific requirements. Its main features include a highly customizable platform, allowing users to tailor functions according to their unique needs. The CW_10 integrates seamlessly with existing infrastructure, making it easy to implement without significant disruptions to current operations. This model emphasizes energy efficiency, contributing to reduced operational costs and promoting sustainability within industry practices.

In conclusion, Emerson Process Management's CW_31, CW_35, and CW_10 models each bring distinct advantages to the table, catering to varying operational needs. Whether it is the compact efficiency of the CW_31, the reliability and performance of the CW_35, or the flexibility of the CW_10, these systems exemplify Emerson's commitment to delivering innovative solutions in process management. Their advanced technologies, combined with robust features, position them as leaders in modern industrial automation.