Rosemount specifications

Emerson Process Management Rosemount is a leading provider of measurement and analytical instrumentation for process industries worldwide. Renowned for its innovative technologies and robust product offerings, Rosemount plays a pivotal role in enhancing productivity, reliability, and safety in various sectors, including oil and gas, chemicals, water and wastewater, power generation, and food and beverage.One of the most notable features of Rosemount products is their precision and accuracy. The Rosemount pressure transmitters are designed to deliver highly accurate measurements, even in the most challenging environments. This accuracy is especially critical in industries where regulatory compliance and safety are paramount. In addition, the transmitters boast advanced noise immunity and superior signal processing, helping ensure that operators receive reliable data.

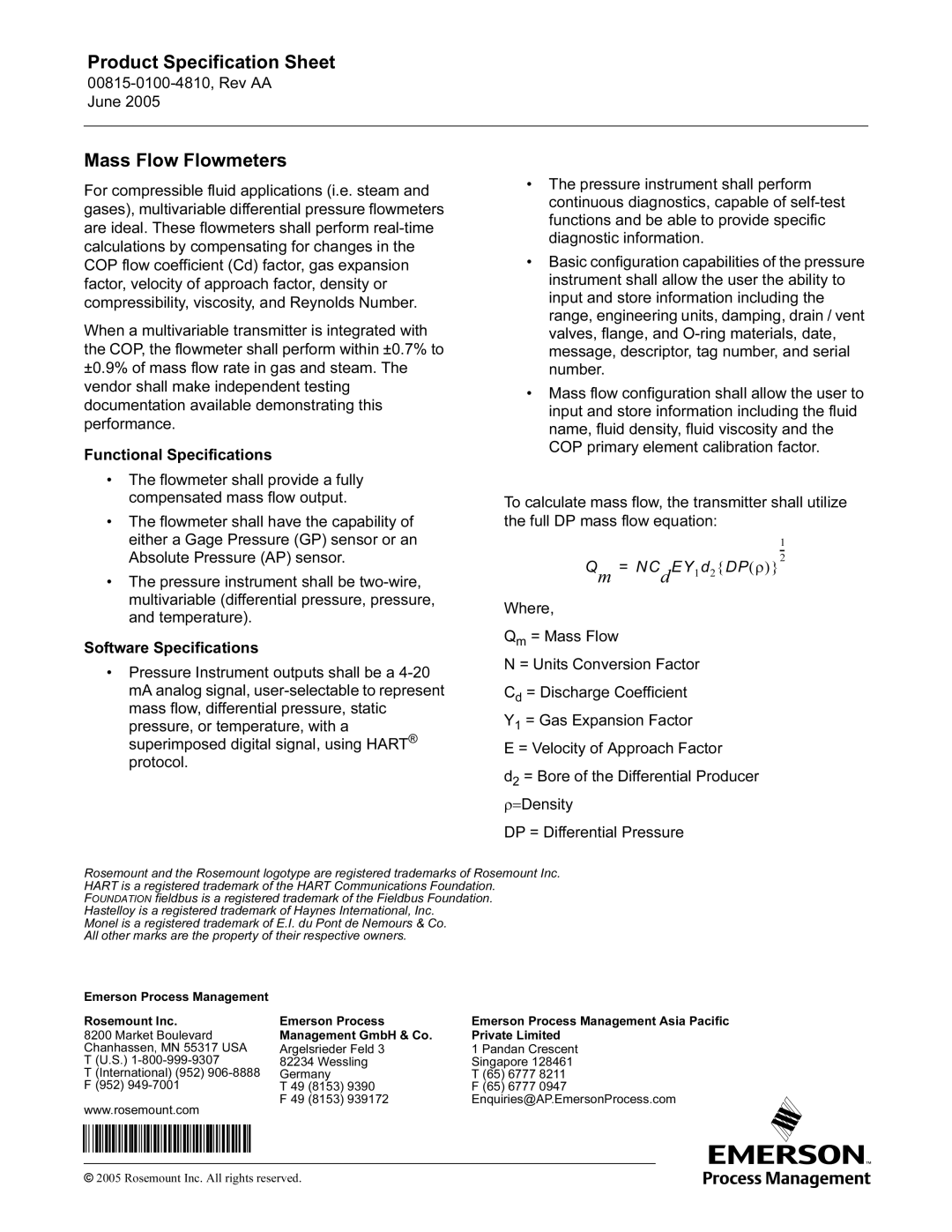

Rosemount technology is centered around the integration of digital capabilities into traditional measurement instruments. Many Rosemount devices are equipped with the Foundation Fieldbus and HART communication protocols, allowing for seamless communication with control systems. This integration facilitates real-time data monitoring, predictive maintenance, and process optimization. Through advanced diagnostics and predictive analytics, operators can identify potential issues before they escalate, leading to reduced downtime and improved operational efficiency.

The product range includes a variety of sensors and transmitters tailored for specific applications, such as flow, level, temperature, and pressure measurement. For instance, the Rosemount 3051 Pressure Transmitter is well-regarded for its ability to provide accurate level measurements in tanks, while the Rosemount 8700 series is notable for its advanced flow measurement technology.

Additionally, the Rosemount 5300 series of radar level transmitters exemplifies cutting-edge technology. These non-contact devices are capable of measuring levels in challenging conditions, including high temperatures and pressures, making them ideal for a wide range of applications across industries.

Another important characteristic of Emerson Process Management Rosemount is its commitment to sustainability and safety. Their products are designed with environmentally friendly principles, ensuring minimal impact on the environment while maintaining the highest safety standards for workers and facilities.

With a strong focus on innovation, reliability, and customer support, Emerson Process Management Rosemount continues to lead the way in process management solutions, helping industries operate more efficiently and safely while maximizing their investment in automation technologies.