HS125FAV, HS55FAV, HS85FAV, MH55FAV, MH125FAV specifications

Enerco's series of industrial heaters, including the TS55FAV, HS85FAV, MH55FAV, MH85FAV, and MH125FAV models, are designed to provide efficient, reliable heating solutions for various applications. These heaters cater to diverse needs, from construction sites to workshops, ensuring optimal comfort and safety even under challenging conditions.The Enerco TS55FAV model stands out for its portable design and substantial heating capacity. It offers an impressive 55,000 BTU output, making it suitable for medium-sized spaces. Its advanced safety features, including a tip-over shut-off switch and a built-in thermostat, help maintain a stable environment. The durable construction ensures longevity while being easy to transport.

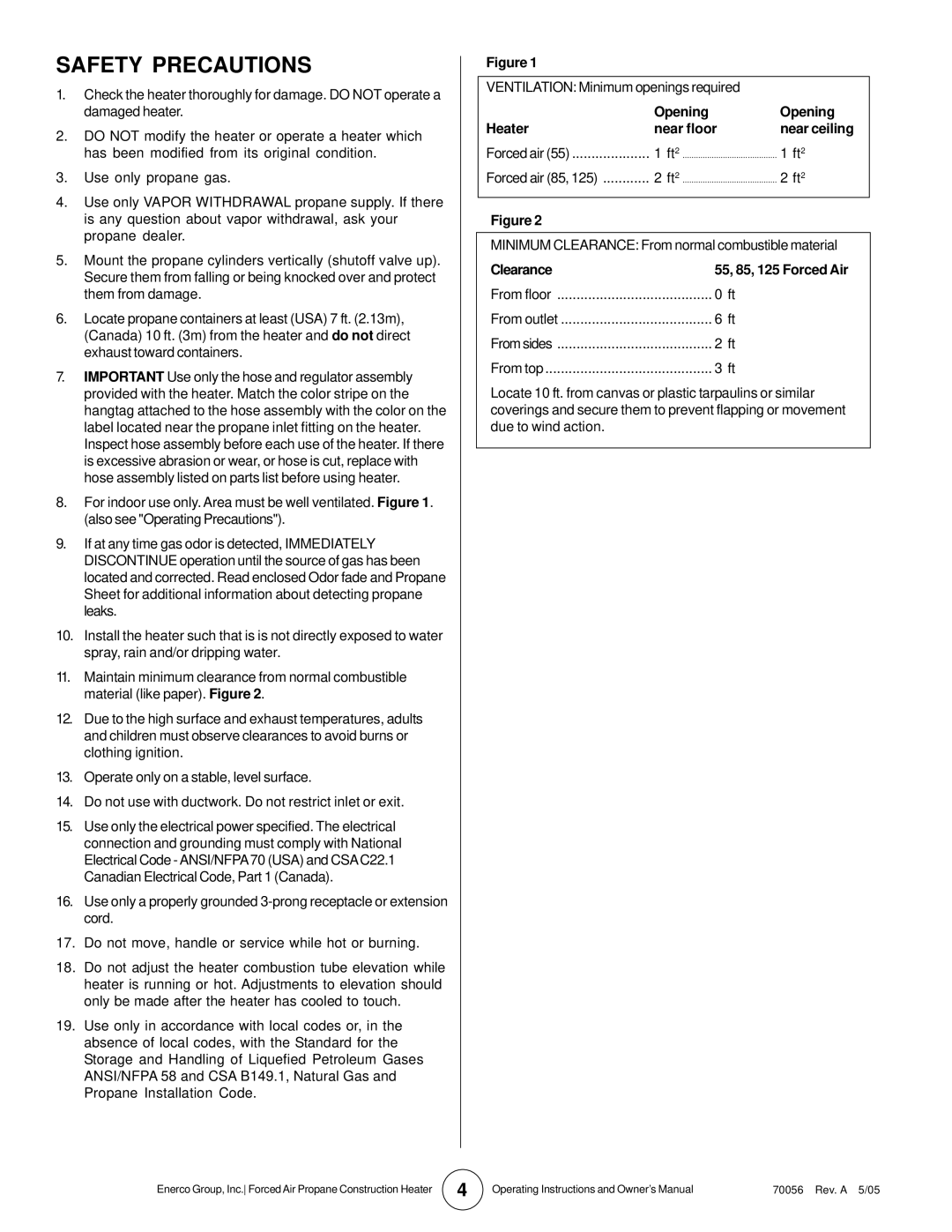

Next in the lineup is the HS85FAV, which delivers an output of up to 85,000 BTUs. This model is particularly noted for its efficient fuel consumption and exceptional performance. The HS85FAV incorporates a forced air system, ensuring quick heat distribution. Its rugged design makes it ideal for outdoor use in harsh weather conditions.

The MH55FAV brings versatility to the series by offering both direct and indirect heating options. This model's 55,000 BTU output makes it a reliable choice for temporary heating needs. It utilizes innovative technology that allows for the efficient burning of fuels while minimizing emissions. Additionally, the MH55FAV features a sturdy frame that allows for easy mobility across job sites.

The MH85FAV is an upgrade, pushing the output to 85,000 BTUs, further enhancing its capability for larger spaces. It carries the same focus on environmental considerations with low emissions and high fuel efficiency. The MH85FAV's ergonomic design and ease of use simplify operation, making it a preferred option for contractors.

At the top of the range is the MH125FAV, boasting an impressive output of 125,000 BTUs. This model is engineered for heavy-duty applications, delivering robust heating for extensive areas. Its built-in thermostat and safety shut-off features ensure that users can operate it with confidence. The MH125FAV also includes a high-performance blower for optimal heat dispersal, making it ideal for challenging industrial environments.

In summary, the Enerco heaters TS55FAV, HS85FAV, MH55FAV, MH85FAV, and MH125FAV represent a comprehensive range of heating solutions, each equipped with unique features and technologies designed for performance, safety, and efficiency. Whether for construction, industrial facilities, or outdoor events, these models meet the diverse requirements of users, ensuring warm environments in various settings.