Maintenance

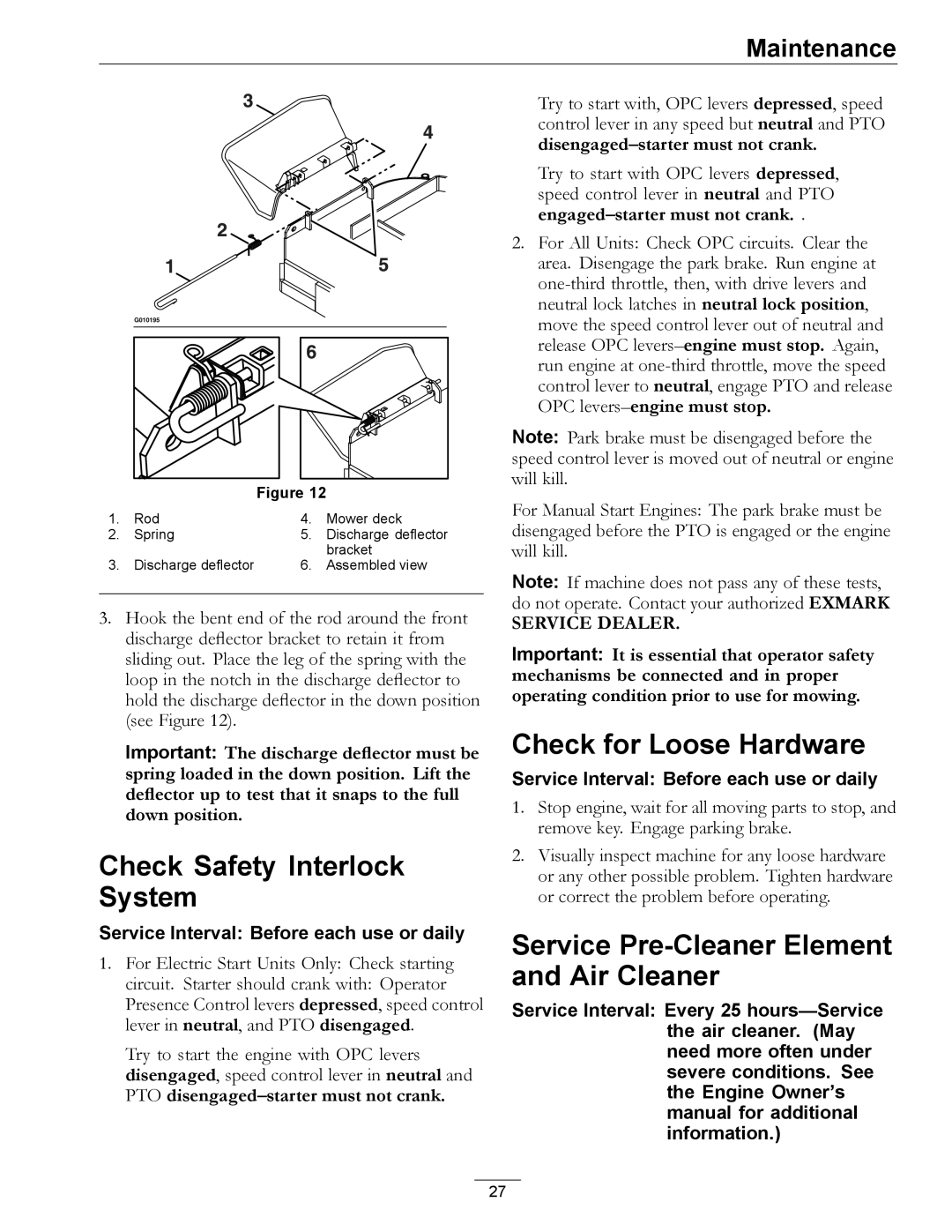

Figure 12

1. | Rod | 4. | Mower deck |

2. | Spring | 5. | Discharge deflector |

|

|

| bracket |

3. | Discharge deflector | 6. | Assembled view |

3.Hook the bent end of the rod around the front discharge deflector bracket to retain it from sliding out. Place the leg of the spring with the loop in the notch in the discharge deflector to hold the discharge deflector in the down position (see Figure 12).

Important: The discharge deflector must be spring loaded in the down position. Lift the deflector up to test that it snaps to the full down position.

Check Safety Interlock System

Service Interval: Before each use or daily

1.For Electric Start Units Only: Check starting

circuit. Starter should crank with: Operator Presence Control levers depressed, speed control lever in neutral, and PTO disengaged.

Try to start the engine with OPC levers disengaged, speed control lever in neutral and PTO

Try to start with, OPC levers depressed, speed control lever in any speed but neutral and PTO

Try to start with OPC levers depressed, speed control lever in neutral and PTO

2.For All Units: Check OPC circuits. Clear the area. Disengage the park brake. Run engine at

Note: Park brake must be disengaged before the speed control lever is moved out of neutral or engine will kill.

For Manual Start Engines: The park brake must be disengaged before the PTO is engaged or the engine will kill.

Note: If machine does not pass any of these tests, do not operate. Contact your authorized EXMARK

SERVICE DEALER.

Important: It is essential that operator safety mechanisms be connected and in proper operating condition prior to use for mowing.

Check for Loose Hardware

Service Interval: Before each use or daily

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

2.Visually inspect machine for any loose hardware or any other possible problem. Tighten hardware or correct the problem before operating.

Service Pre-Cleaner Element and Air Cleaner

Service Interval: Every 25

27