Maintenance

Lubricate Grease Fittings

Note: See chart for service intervals.

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

2.Lubricate fittings with one to two pumps of NGLI grade #2

Refer to the following chart for fitting locations and lubrication schedule.

Lubrication Chart

| Fitting | Initial | Number of | Service |

Locations | Pumps | Places | Interval | |

1. | Belt | 1 | 2 | 25 Hours |

Idlers |

|

|

| |

2. | Deck | 1 | 4 | 40 Hours |

Pivots |

|

|

| |

3. | Front | *0 | 2 | *Yearly |

Caster |

|

|

| |

Wheel |

|

|

| |

Bearings |

|

|

| |

4. | Front | *0 | 2 | *Yearly |

Caster |

|

|

| |

Pivots |

|

|

| |

5. | Brake | 1 | 1 | 160 Hours |

Handle |

|

|

| |

Pivot |

|

|

| |

*See step 3 for special lubrication instructions on the front caster pivots and the Lubricate Caster Wheel Hubs section for special lubrication instructions on the front casters wheel hubs.

3.Lubricate front caster pivots once a year. Remove hex plug and cap. Thread grease zerk in hole and

pump with grease until it oozes out around top bearing. Remove grease zerk and thread plug back in. Place cap back on.

Lubricate Caster Wheel Hubs

Service Interval: Yearly

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

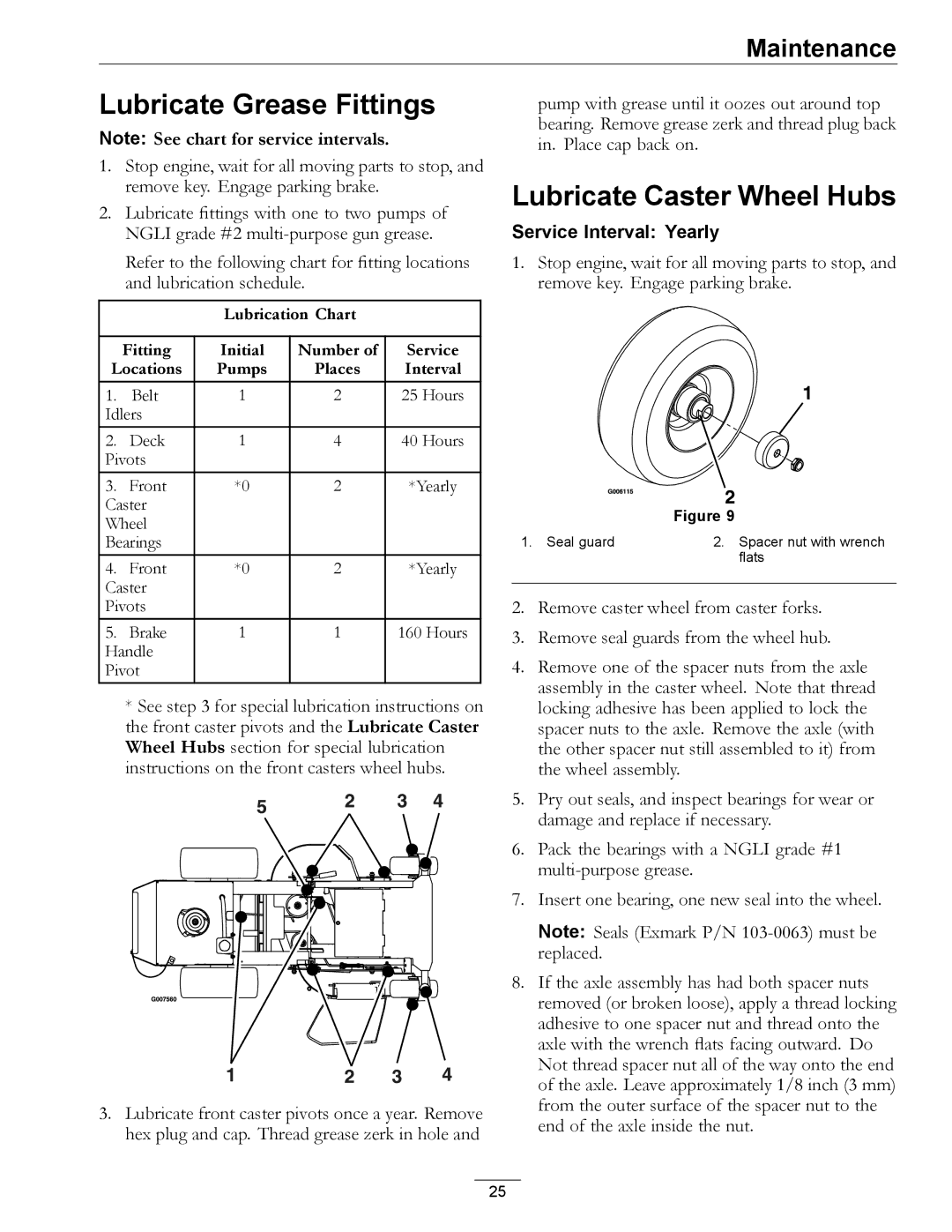

| Figure 9 |

1. Seal guard | 2. Spacer nut with wrench |

| flats |

2.Remove caster wheel from caster forks.

3.Remove seal guards from the wheel hub.

4.Remove one of the spacer nuts from the axle assembly in the caster wheel. Note that thread locking adhesive has been applied to lock the spacer nuts to the axle. Remove the axle (with the other spacer nut still assembled to it) from the wheel assembly.

5.Pry out seals, and inspect bearings for wear or damage and replace if necessary.

6.Pack the bearings with a NGLI grade #1

7.Insert one bearing, one new seal into the wheel.

Note: Seals (Exmark P/N

8.If the axle assembly has had both spacer nuts removed (or broken loose), apply a thread locking adhesive to one spacer nut and thread onto the axle with the wrench flats facing outward. Do Not thread spacer nut all of the way onto the end of the axle. Leave approximately 1/8 inch (3 mm) from the outer surface of the spacer nut to the end of the axle inside the nut.

25