C-480C, 480C, C-480HS, C-480, 480 specifications

Fellowes has established itself as a prominent player in the field of shredders, offering a range designed for security and efficiency in document handling. Among its highly regarded products are the Fellowes C-480, C-480HS, 480, 480-2HS, and 480C. Each model showcases a unique blend of features catered to meet diverse shredding needs, making them ideal for home or office use.The Fellowes C-480 is built with powerful cutting technology capable of shredding up to 12 sheets of paper at once. Its cross-cut design ensures that documents are turned into tiny confetti-like pieces, adhering to P-4 security standards, making it suitable for confidential information. The C-480 also features a 4-gallon waste bin, allowing for extended usage without constant emptying.

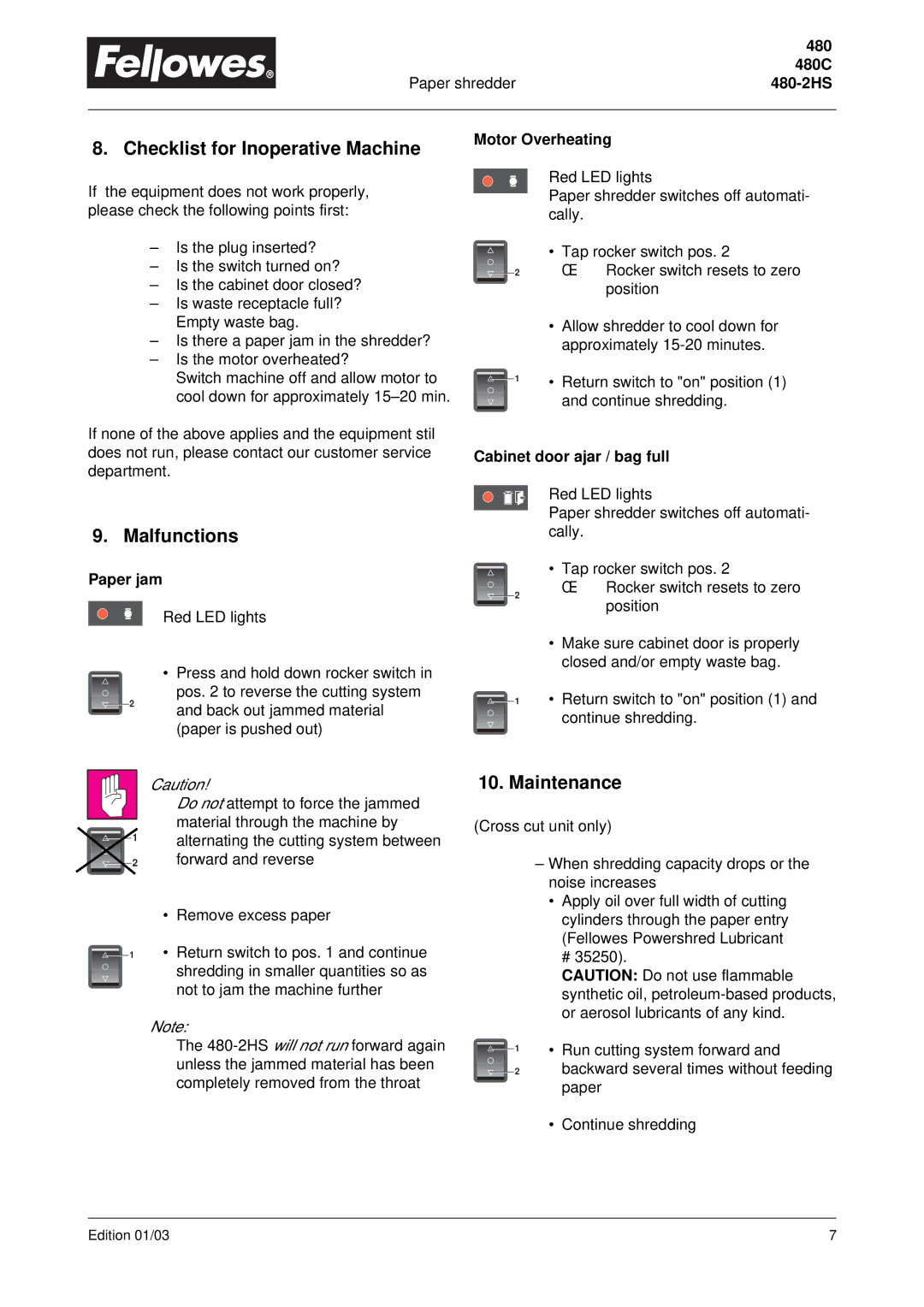

The C-480HS is an upgraded version of the C-480, offering the same capacity but enhanced with a safety lock feature. This ensures the shredder is not inadvertently activated, making it a safer choice for work environments where multiple users may be present. The model also includes an advanced jam prevention technology that automatically reverses to clear jams, promoting seamless operation.

The Fellowes 480 brings more versatility with its ability to handle credit cards, staples, and paper clips alongside regular paper shredding. This versatility is critical for offices with a heavy volume of documents, especially when combining non-paper items. The 480 model also has a decent capacity, allowing for smooth processing of 12 sheets at a time, while its quiet operation feature makes it a popular choice for noise-sensitive environments.

For those looking for dual functionality, the Fellowes 480-2HS stands out with two separate feed slots to manage both micro-cut and cross-cut shredding. This allows users to easily switch between shredding styles based on their specific security requirements. The dual-head technology enhances security, ensuring comprehensive protection for sensitive documents.

Lastly, the Fellowes 480C incorporates smart shredder technology that automatically detects the weight of the paper fed to it, enabling optimal shredding capacity while preventing jams. This intuitive feature paired with its reasonable waste capacity makes the 480C an efficient choice for daily shredding tasks.

Overall, the Fellowes C-480 series exemplifies reliability and innovation in document security, empowering users with a variety of shredding options tailored to their needs. Whether for individual use or in busy office settings, these models offer the technology and features needed for effective document management.