asked of it, the drill will shut down to protect the battery.

This is an important feature that might be misunderstood by many users. Even though the drill seems to have plenty of power for a moderate load, if you try to take a heavy load from a low battery, it will shut down the motor to protect the battery. Other drills will allow you to

Gearbox

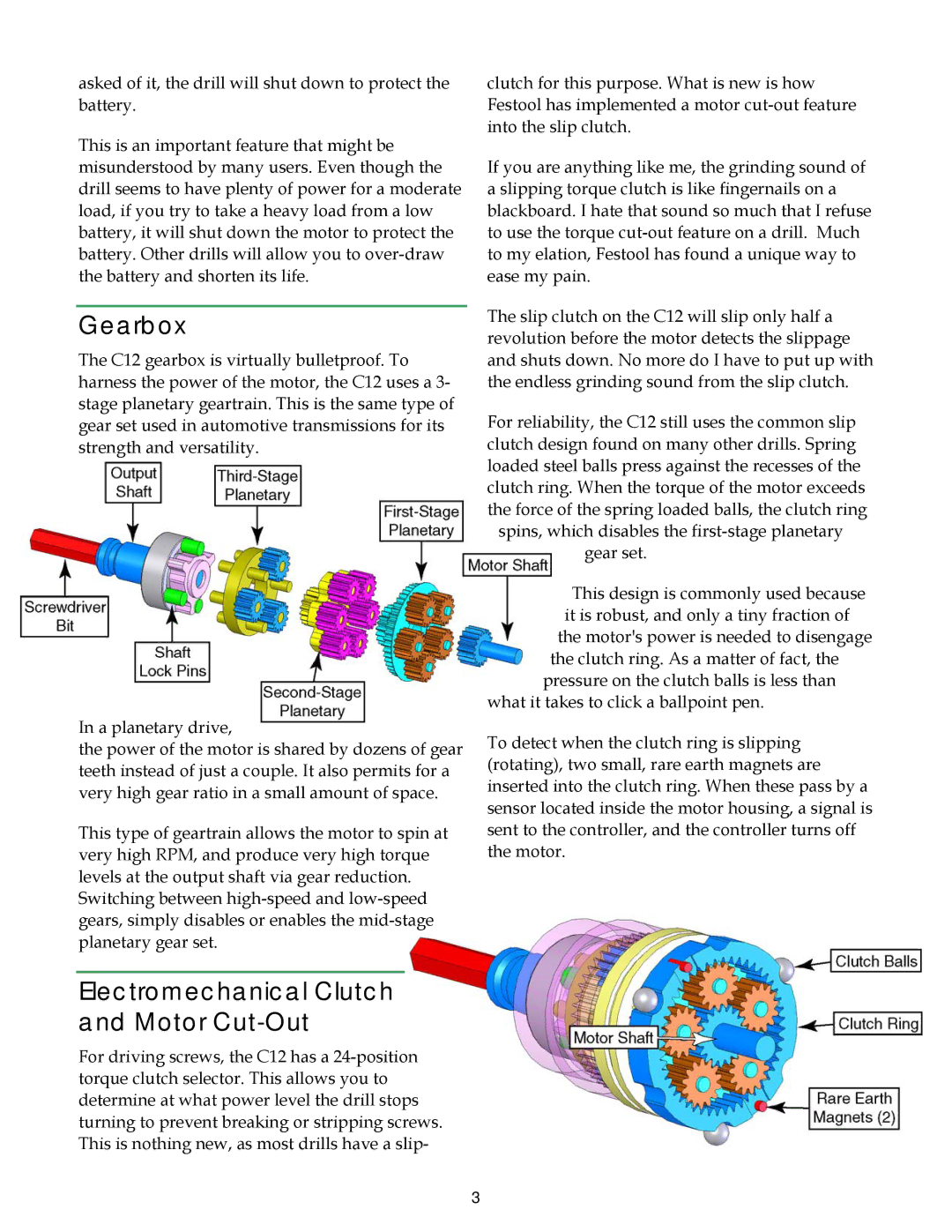

The C12 gearbox is virtually bulletproof. To harness the power of the motor, the C12 uses a 3- stage planetary geartrain. This is the same type of gear set used in automotive transmissions for its strength and versatility.

In a planetary drive,

the power of the motor is shared by dozens of gear teeth instead of just a couple. It also permits for a very high gear ratio in a small amount of space.

This type of geartrain allows the motor to spin at very high RPM, and produce very high torque levels at the output shaft via gear reduction. Switching between

Electromechanical Clutch and Motor Cut-Out

For driving screws, the C12 has a

clutch for this purpose. What is new is how Festool has implemented a motor

If you are anything like me, the grinding sound of a slipping torque clutch is like fingernails on a blackboard. I hate that sound so much that I refuse to use the torque

The slip clutch on the C12 will slip only half a revolution before the motor detects the slippage and shuts down. No more do I have to put up with the endless grinding sound from the slip clutch.

For reliability, the C12 still uses the common slip clutch design found on many other drills. Spring loaded steel balls press against the recesses of the clutch ring. When the torque of the motor exceeds the force of the spring loaded balls, the clutch ring

spins, which disables the

This design is commonly used because it is robust, and only a tiny fraction of the motor's power is needed to disengage the clutch ring. As a matter of fact, the pressure on the clutch balls is less than

what it takes to click a ballpoint pen.

To detect when the clutch ring is slipping (rotating), two small, rare earth magnets are inserted into the clutch ring. When these pass by a sensor located inside the motor housing, a signal is sent to the controller, and the controller turns off the motor.

3