SI256E, 103-BQS specifications

The Foundations SI256E,103-BQS is an advanced synthetic insulation material that has garnered attention for its innovative features and technologies. It is designed to meet the demanding needs of various industries, ensuring optimal thermal performance while maintaining flexibility and durability.One of the main features of the SI256E,103-BQS is its exceptional thermal resistance. This insulation solution is engineered to provide superior thermal performance, making it ideal for applications in extreme temperature conditions. The material's unique composition minimizes heat loss, ensuring energy efficiency in commercial and industrial settings. This is particularly beneficial in sectors such as aerospace, automotive, and construction, where thermal management is critical.

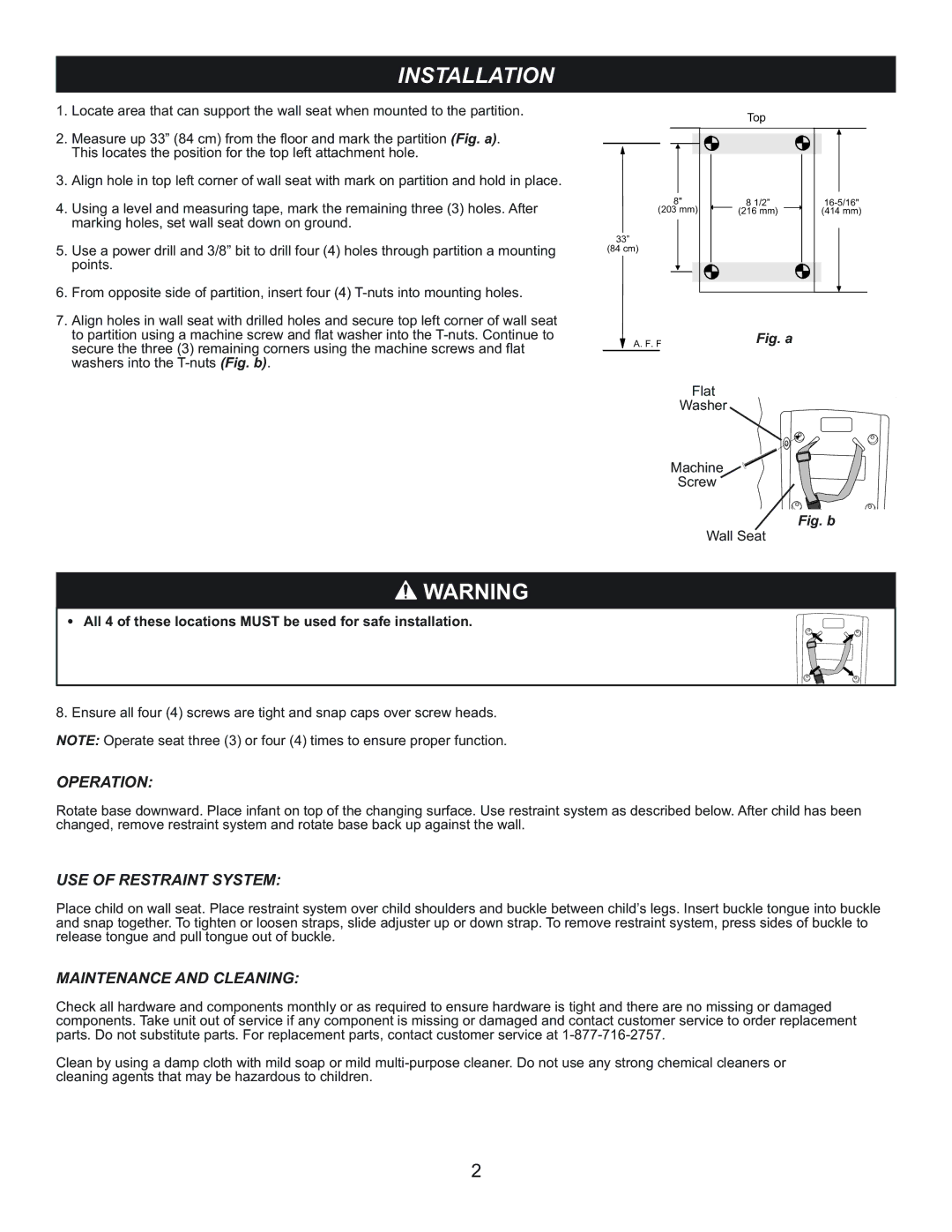

The SI256E,103-BQS also boasts impressive moisture resistance. This characteristic prevents water infiltration, which can compromise the integrity of insulation systems. Its hydrophobic properties enable it to repel moisture, making it suitable for use in environments where humidity and exposure to water are concerns. This feature extends the lifespan of the insulation, reducing maintenance costs and enhancing overall performance.

Another significant characteristic of the SI256E,103-BQS is its lightweight nature. This feature simplifies installation and reduces labor costs, as the material is easy to handle and transport. Its lightweight design does not compromise on strength, allowing for robust applications without the added weight burden that may affect structural integrity.

The Foundations SI256E,103-BQS also incorporates advanced technologies such as nanotechnology and enhanced fiber structures. These innovations contribute to the material's strength and stability, ensuring it can withstand mechanical stresses while maintaining its insulating properties. Furthermore, the material is designed to be environmentally friendly, aligning with the growing demand for sustainable solutions in various industries.

In conclusion, the Foundations SI256E,103-BQS insulation material stands out for its combination of thermal efficiency, moisture resistance, lightweight design, and innovative technologies. Its application spans across multiple sectors, providing reliable performance and contributing to energy conservation efforts. As industries continue to prioritize sustainability and efficiency, the SI256E,103-BQS positions itself as a leading choice for advanced insulation solutions.