Multi-shallow Well Points (Figure 2)

The

Install a check valve or a fine screen well point on each well to ensure the pump maintains prime. The flow arrow on a check valve must point toward the pump.

Figure 2

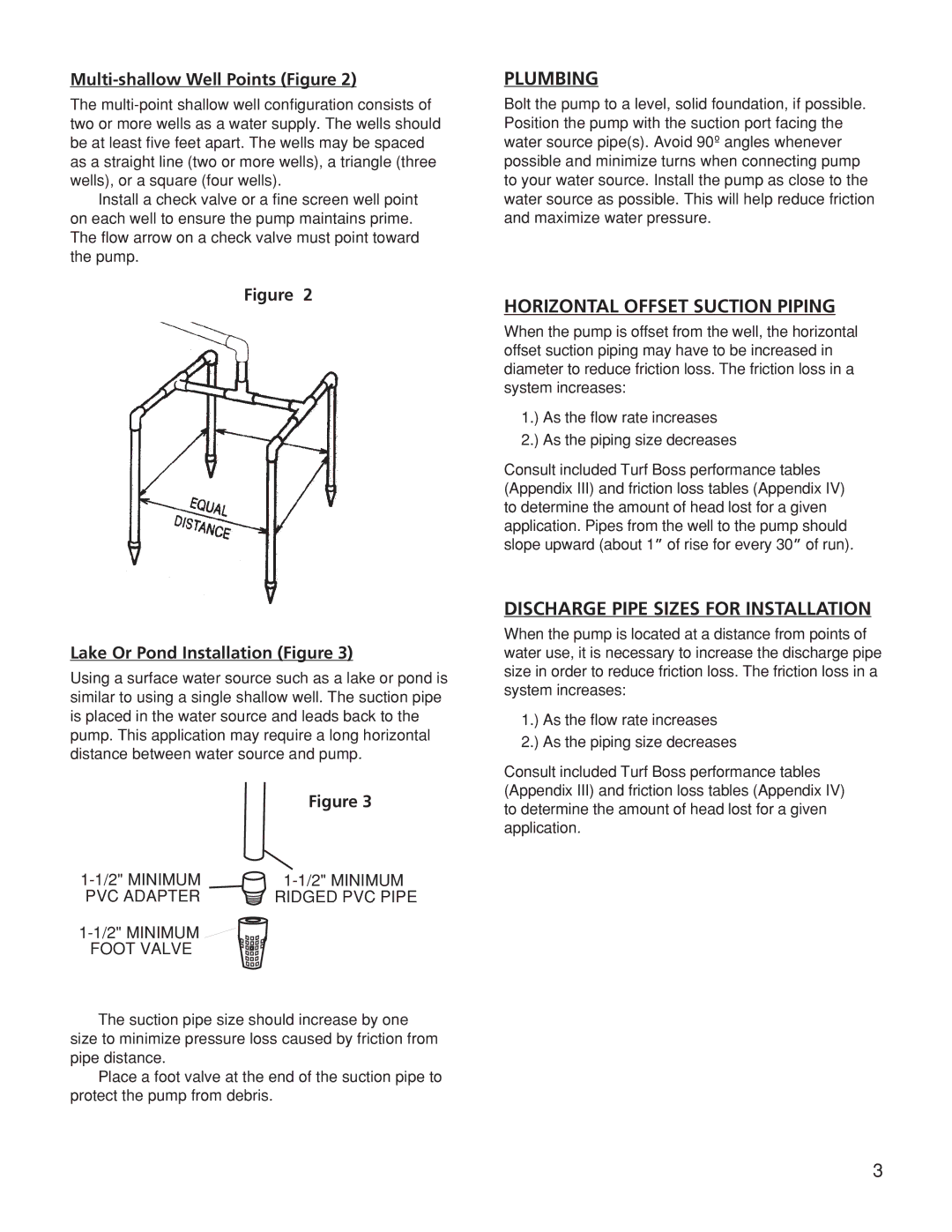

Lake Or Pond Installation (Figure 3)

Using a surface water source such as a lake or pond is similar to using a single shallow well. The suction pipe is placed in the water source and leads back to the pump. This application may require a long horizontal distance between water source and pump.

Figure 3

PVC ADAPTER | RIDGED PVC PIPE |

![]()

FOOT VALVE

The suction pipe size should increase by one size to minimize pressure loss caused by friction from pipe distance.

Place a foot valve at the end of the suction pipe to protect the pump from debris.

PLUMBING

Bolt the pump to a level, solid foundation, if possible. Position the pump with the suction port facing the water source pipe(s). Avoid 90º angles whenever possible and minimize turns when connecting pump to your water source. Install the pump as close to the water source as possible. This will help reduce friction and maximize water pressure.

HORIZONTAL OFFSET SUCTION PIPING

When the pump is offset from the well, the horizontal offset suction piping may have to be increased in diameter to reduce friction loss. The friction loss in a system increases:

1.) As the flow rate increases

2.) As the piping size decreases

Consult included Turf Boss performance tables (Appendix III) and friction loss tables (Appendix IV) to determine the amount of head lost for a given application. Pipes from the well to the pump should slope upward (about 1” of rise for every 30” of run).

DISCHARGE PIPE SIZES FOR INSTALLATION

When the pump is located at a distance from points of water use, it is necessary to increase the discharge pipe size in order to reduce friction loss. The friction loss in a system increases:

1.) As the flow rate increases

2.) As the piping size decreases

Consult included Turf Boss performance tables (Appendix III) and friction loss tables (Appendix IV) to determine the amount of head lost for a given application.

3