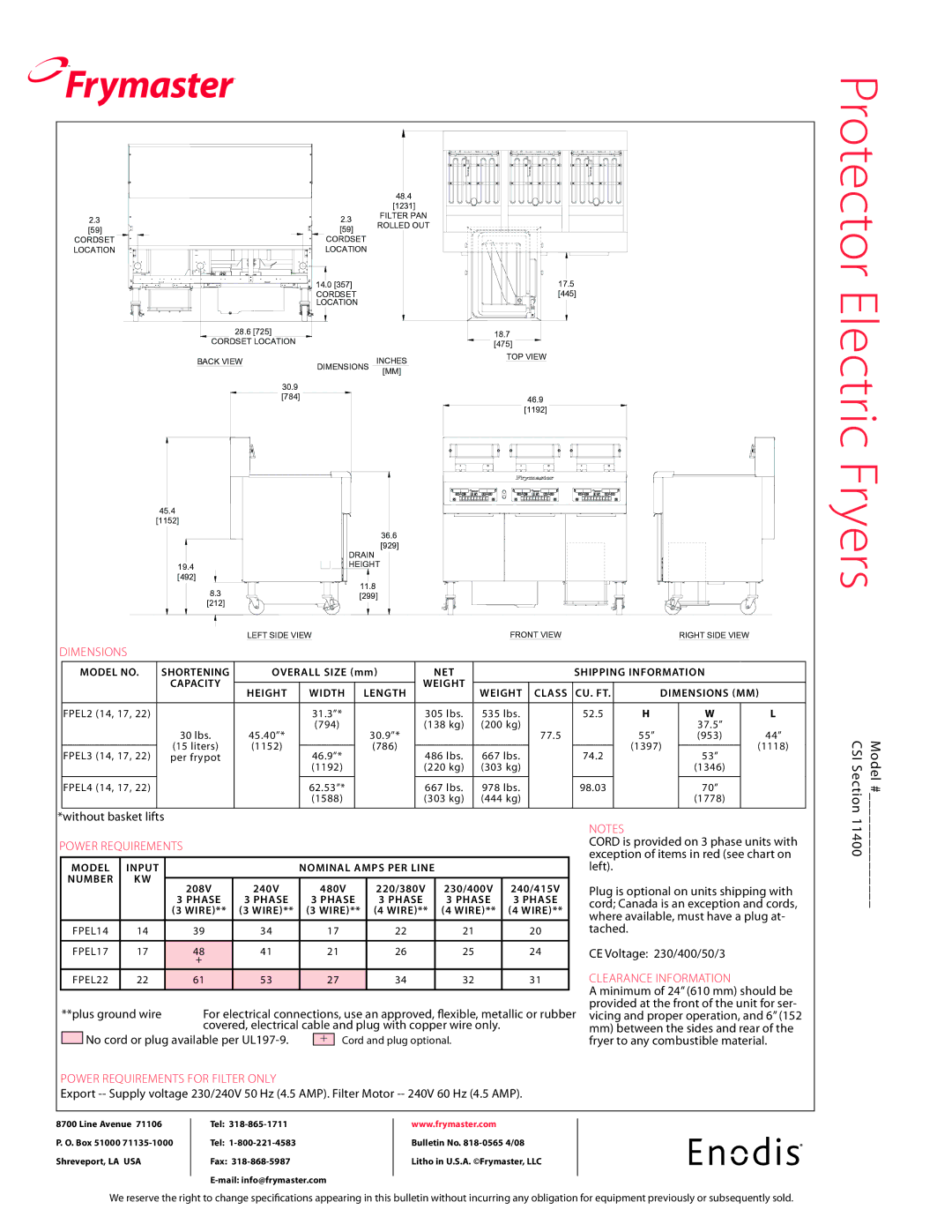

FPEL214, FPEL414, FPEL422, FPEL322, FPEL317 specifications

Frymaster, a leader in commercial frying equipment, offers a range of high-performance fryers designed for efficiency, precision, and durability. Among their most notable models are the Frymaster FPEL217, FPEL214, FPEL417, FPEL317, and FPEL222, each designed to meet the diverse needs of the food service industry.The Frymaster FPEL217 is a standout model known for its versatile design and energy efficiency. It features an advanced electronic control system that allows for precise temperature control, ensuring optimal frying results. The model is equipped with a high-quality filtration system that extends oil life, enhancing the flavor of fried foods while reducing operational costs.

Similarly, the FPEL214 is designed with operator convenience in mind. This fryer includes a built-in filtration system that automatically cleans oil, reducing labor time and ensuring consistent food quality. Its compact design makes it ideal for smaller kitchens while still providing a generous frying capacity.

The Frymaster FPEL417 offers an impressive frying capacity, making it suitable for high-volume operations. This model is equipped with state-of-the-art digital controls, allowing users to monitor and adjust cooking times and temperatures easily. Its stainless steel construction ensures longevity and easy maintenance, making it a reliable choice for busy establishments.

The FPEL317 model combines efficiency with innovative technology. It features Frymaster's Advanced Oil Management System, which allows for real-time monitoring of oil quality. This technology ensures that the oil is always at optimal performance levels, maximizing flavor and minimizing waste. Additionally, this fryer is designed for easy cleanup, with accessible components that simplify routine maintenance.

Lastly, the FPEL222 model caters to medium-volume operations, offering a blend of efficiency and capacity. It boasts a robust frying system that delivers consistent results and is fitted with a mechanical thermostat for reliable temperature control. The FPEL222 also features a versatile design, allowing it to adapt to various frying needs.

In summary, the Frymaster FPEL series offers an array of fryers that leverage advanced technologies to enhance cooking efficiency, maintain food quality, and extend oil life. With a focus on durability and ease of use, these models are well-suited for the demands of the modern kitchen, ensuring that food service businesses can consistently deliver delicious fried offerings.