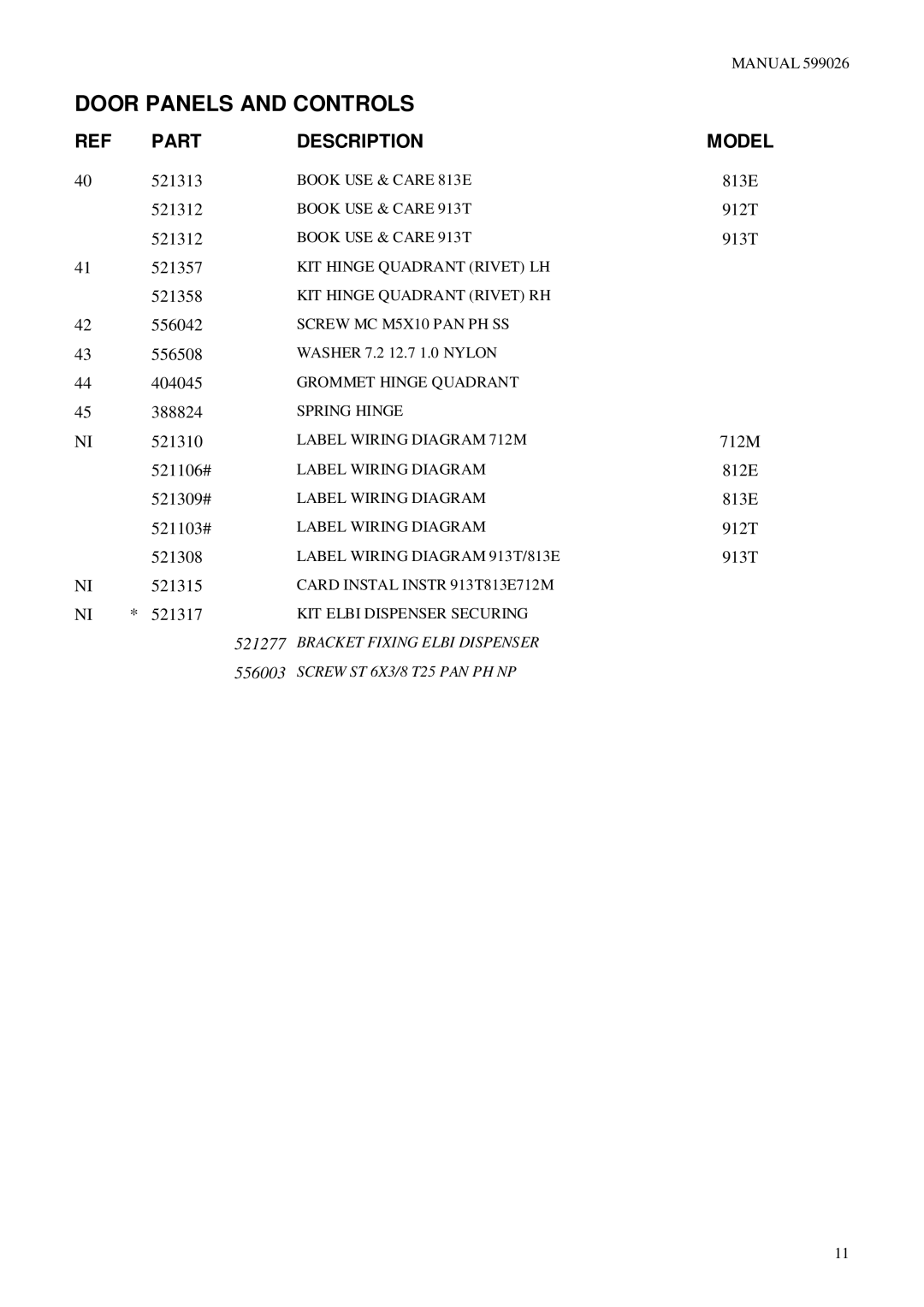

813E, 913T, 712M, 912T, 812E specifications

The GE 812E, 912T, 712M, 913T, and 813E are part of General Electric's robust lineup of industrial gas turbines, designed to meet the growing demand for efficient, clean, and flexible energy solutions. Each model offers distinct features, characteristics, and technologies tailored for various operational needs in the energy sector.The GE 812E is known for its exceptional efficiency and reliability. It utilizes advanced aerodynamics and materials technology to enhance performance and reduce emissions. This model is particularly suited for peaking power applications, where quick start-up times and operational flexibility are crucial. Its modular design allows for simplified maintenance and reduced downtime, making it a preferred choice for utilities.

The 912T model, on the other hand, boasts a higher power output with enhanced thermal efficiency. Utilizing cutting-edge turbine blade cooling techniques and advanced combustion system designs, the 912T achieves lower nitrogen oxide (NOx) emissions. This model is primarily used in combined cycle power plants, where its ability to operate at varying loads increases overall system efficiency and reduces operational costs.

The GE 712M gas turbine is recognized for its compact size and high power density, making it ideal for mid-sized power generation systems. It incorporates advanced digital controls for optimized operation and improved fuel efficiency. Its lightweight and robust design ensures ease of installation and versatility in diverse environments, from traditional power plants to distributed generation applications.

The 913T is engineered for enhanced performance in combined cycle configurations. This gas turbine features advanced materials that withstand high temperatures and pressure, leading to improved reliability and efficiency. Moreover, it incorporates state-of-the-art diagnostics and predictive maintenance capabilities, which minimize unplanned outages and maximize uptime.

Lastly, the GE 813E is designed for flexibility and high efficiency, capable of operating on a wide range of fuels including natural gas, biogas, and synthetic fuels. Its innovative cooling technologies and combustion system allow it to maintain efficiency while minimizing pollutants. This model is particularly effective in maximizing the economic and environmental benefits for operators, particularly in areas with stringent emission regulations.

Together, the GE 812E, 912T, 712M, 913T, and 813E gas turbines represent advanced solutions for modern energy challenges, combining high performance, reliability, and technological innovation to provide sustainable energy options for the future.