PNRQ20, PNRV12, PNRV18, GXRM10, PNRQ15 specifications

The GE GXRM10, PNRV18, PNRQ15, PNRQ20, and GXRV10 are a series of advanced power systems designed to meet a wide range of industrial needs. Each unit brings a unique set of features, technologies, and characteristics that cater to various applications in the power generation and distribution industry.Starting with the GE GXRM10, this model is known for its robust performance and reliability. It integrates advanced digital technology, allowing for real-time monitoring and control. Key features include modular design, which facilitates easy upgrades and maintenance. It also offers exceptional efficiency, reducing operational costs and minimizing environmental impact.

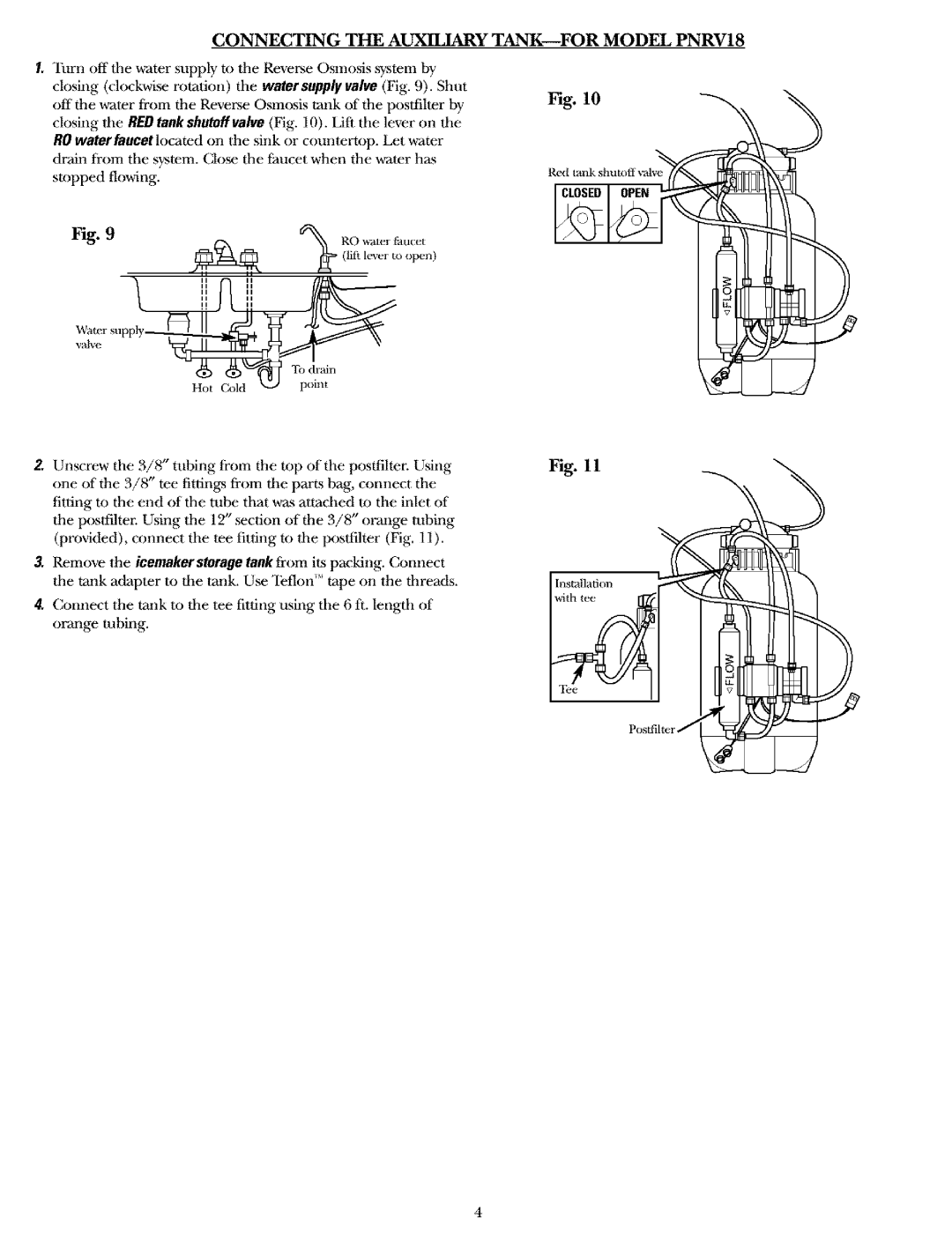

The PNRV18 model is engineered for enhanced energy management. Its defining characteristic is its ability to efficiently regulate voltage levels, contributing to a stable power supply. Equipped with smart grid capabilities, it supports integration with renewable energy sources, making it a forward-thinking solution for modern energy challenges. Furthermore, its compact design allows for flexibility in installation.

Meanwhile, the PNRQ15 and PNRQ20 models are designed for larger-scale industrial applications. Both units emphasize enhanced load handling capabilities, making them ideal for high-demand environments. These models feature advanced protection mechanisms, ensuring that they can handle fluctuations and surges in power without risking damage to the system. Their user-friendly interface provides operators with easy access to real-time data and analytics, facilitating informed decision-making.

Lastly, the GE GXRV10 stands out with its emphasis on versatility. It can be configured for a variety of operational conditions, providing solutions for both continuous and standby power needs. This model incorporates state-of-the-art communication technology, allowing for seamless integration with existing infrastructure. This adaptability is increasingly crucial as industries shift towards hybrid and decentralized energy models.

In conclusion, the GE GXRM10, PNRV18, PNRQ15, PNRQ20, and GXRV10 represent a significant leap in power system technology. Their innovative features and robust design not only enhance operational efficiency but also align with global trends towards sustainable energy solutions. Each model, with its unique characteristics, provides tailored solutions that meet the evolving needs of various sectors in the energy landscape.