English

EXTENSION CORDS

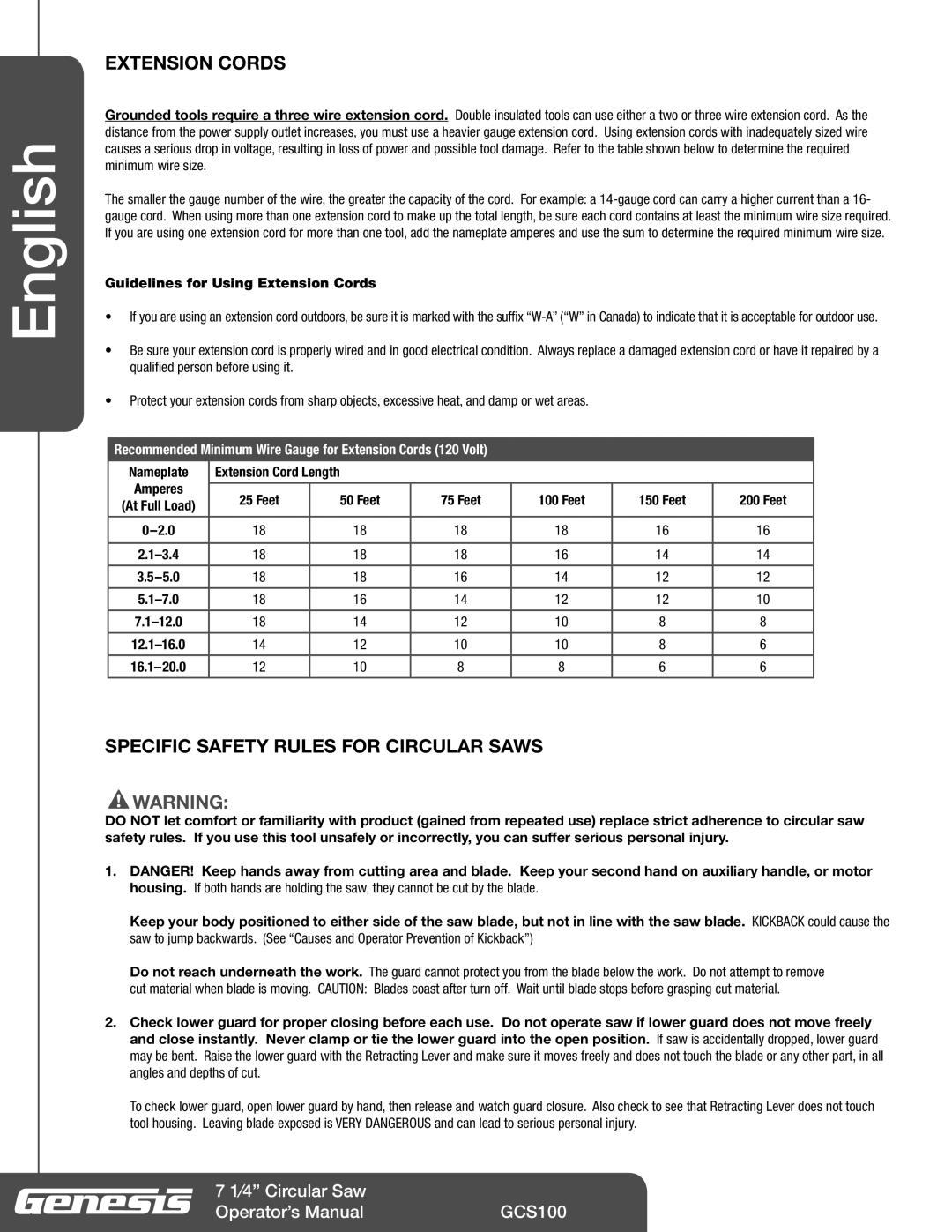

Grounded tools require a three wire extension cord. Double insulated tools can use either a two or three wire extension cord. As the distance from the power supply outlet increases, you must use a heavier gauge extension cord. Using extension cords with inadequately sized wire causes a serious drop in voltage, resulting in loss of power and possible tool damage. Refer to the table shown below to determine the required minimum wire size.

The smaller the gauge number of the wire, the greater the capacity of the cord. For example: a

Guidelines for Using Extension Cords

•If you are using an extension cord outdoors, be sure it is marked with the suffix

•Be sure your extension cord is properly wired and in good electrical condition. Always replace a damaged extension cord or have it repaired by a qualified person before using it.

•Protect your extension cords from sharp objects, excessive heat, and damp or wet areas.

Recommended Minimum Wire Gauge for Extension Cords (120 Volt)

Nameplate | Extension Cord Length |

|

|

|

|

| |

Amperes |

|

|

|

|

|

|

|

25 Feet |

| 50 Feet | 75 Feet | 100 Feet | 150 Feet | 200 Feet | |

(At Full Load) |

| ||||||

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

18 |

| 18 | 18 | 18 | 16 | 16 | |

|

|

|

|

|

|

|

|

18 |

| 18 | 18 | 16 | 14 | 14 | |

|

|

|

|

|

|

|

|

18 |

| 18 | 16 | 14 | 12 | 12 | |

|

|

|

|

|

|

|

|

18 |

| 16 | 14 | 12 | 12 | 10 | |

|

|

|

|

|

|

|

|

18 |

| 14 | 12 | 10 | 8 | 8 | |

|

|

|

|

|

|

|

|

14 |

| 12 | 10 | 10 | 8 | 6 | |

|

|

|

|

|

|

|

|

12 |

| 10 | 8 | 8 | 6 | 6 | |

|

|

|

|

|

|

|

|

SPECIFIC SAFETY RULES FOR CIRCULAR SAWS

![]() Warning:

Warning:

DO NOT let comfort or familiarity with product (gained from repeated use) replace strict adherence to circular saw safety rules. If you use this tool unsafely or incorrectly, you can suffer serious personal injury.

1.DANGER! Keep hands away from cutting area and blade. Keep your second hand on auxiliary handle, or motor housing. If both hands are holding the saw, they cannot be cut by the blade.

Keep your body positioned to either side of the saw blade, but not in line with the saw blade. KICKBACK could cause the saw to jump backwards. (See “Causes and Operator Prevention of Kickback”)

Do not reach underneath the work. The guard cannot protect you from the blade below the work. Do not attempt to remove cut material when blade is moving. CAUTION: Blades coast after turn off. Wait until blade stops before grasping cut material.

2.Check lower guard for proper closing before each use. Do not operate saw if lower guard does not move freely and close instantly. Never clamp or tie the lower guard into the open position. If saw is accidentally dropped, lower guard may be bent. Raise the lower guard with the Retracting Lever and make sure it moves freely and does not touch the blade or any other part, in all angles and depths of cut.

To check lower guard, open lower guard by hand, then release and watch guard closure. Also check to see that Retracting Lever does not touch tool housing. Leaving blade exposed is VERY DANGEROUS and can lead to serious personal injury.

7 1⁄4” Circular Saw |

|

Operator’s Manual | GCS100 |