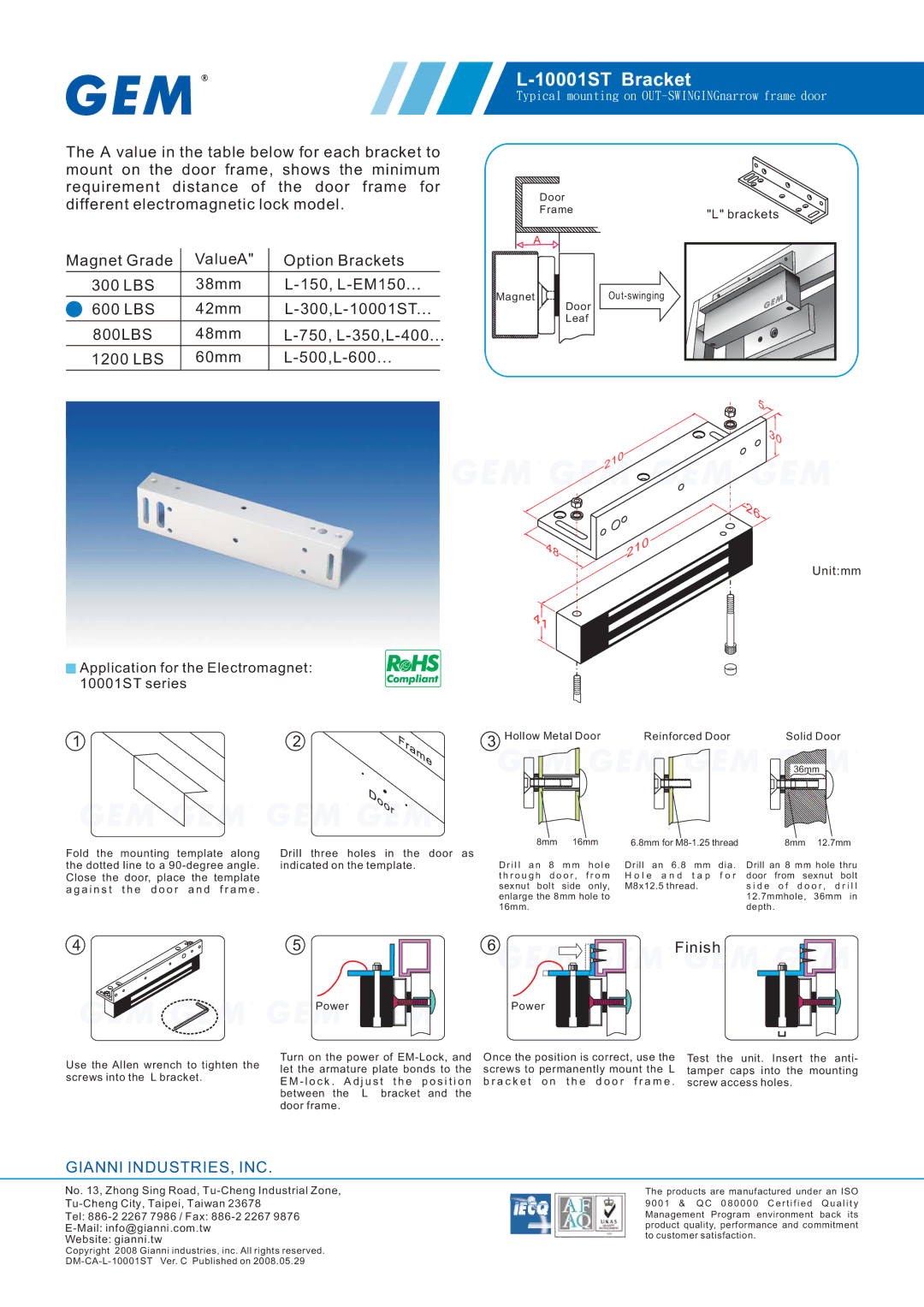

10001ST series specifications

Gianni Industries has firmly established itself as a leader in the realm of innovative industrial solutions, particularly with its groundbreaking 10001ST series. Designed to meet the evolving demands of modern industries, the 10001ST series encapsulates a harmonious blend of advanced technologies, user-centric features, and unparalleled durability.One of the standout features of the 10001ST series is its robust construction, crafted from high-grade materials that ensure longevity even in the most challenging environments. This series has been meticulously engineered to withstand extreme temperatures, moisture, and mechanical stresses, making it ideal for applications in sectors such as manufacturing, telecommunications, and energy production.

The 10001ST series incorporates state-of-the-art automation technologies, allowing for seamless integration into existing production processes. It supports IoT connectivity, enabling real-time monitoring and control through advanced analytics. This feature empowers users to optimize their operations, mitigate downtime, and enhance overall productivity. Integration with cloud platforms provides accessibility to data from anywhere, facilitating informed decision-making.

Enhanced safety protocols are a hallmark of the 10001ST series, which includes built-in sensors and alarms to detect potential hazards. These safety features not only protect personnel but also ensure compliance with industry regulations. Moreover, the system's design focuses on energy efficiency, reducing operational costs and minimizing environmental impact.

User-friendliness sets the 10001ST series apart from its competitors. The intuitive interface and customizable controls allow users to tailor the equipment to their specific requirements. Additionally, comprehensive training resources and customer support further enhance user experience, ensuring that operators can maximize the capabilities of the system.

In terms of versatility, the 10001ST series boasts a wide range of configurations and accessories, catering to various industrial needs. Whether for handling heavy machinery, managing sensitive electronic components, or facilitating complex assembly lines, this series proves adaptable and efficient.

In conclusion, Gianni Industries’ 10001ST series stands at the forefront of industrial technology, seamlessly merging cutting-edge features with a focus on safety, efficiency, and user experience. As industries continue to evolve, the 10001ST series positions itself as an exemplary solution, ready to tackle the challenges of the future while consistently delivering exceptional performance.