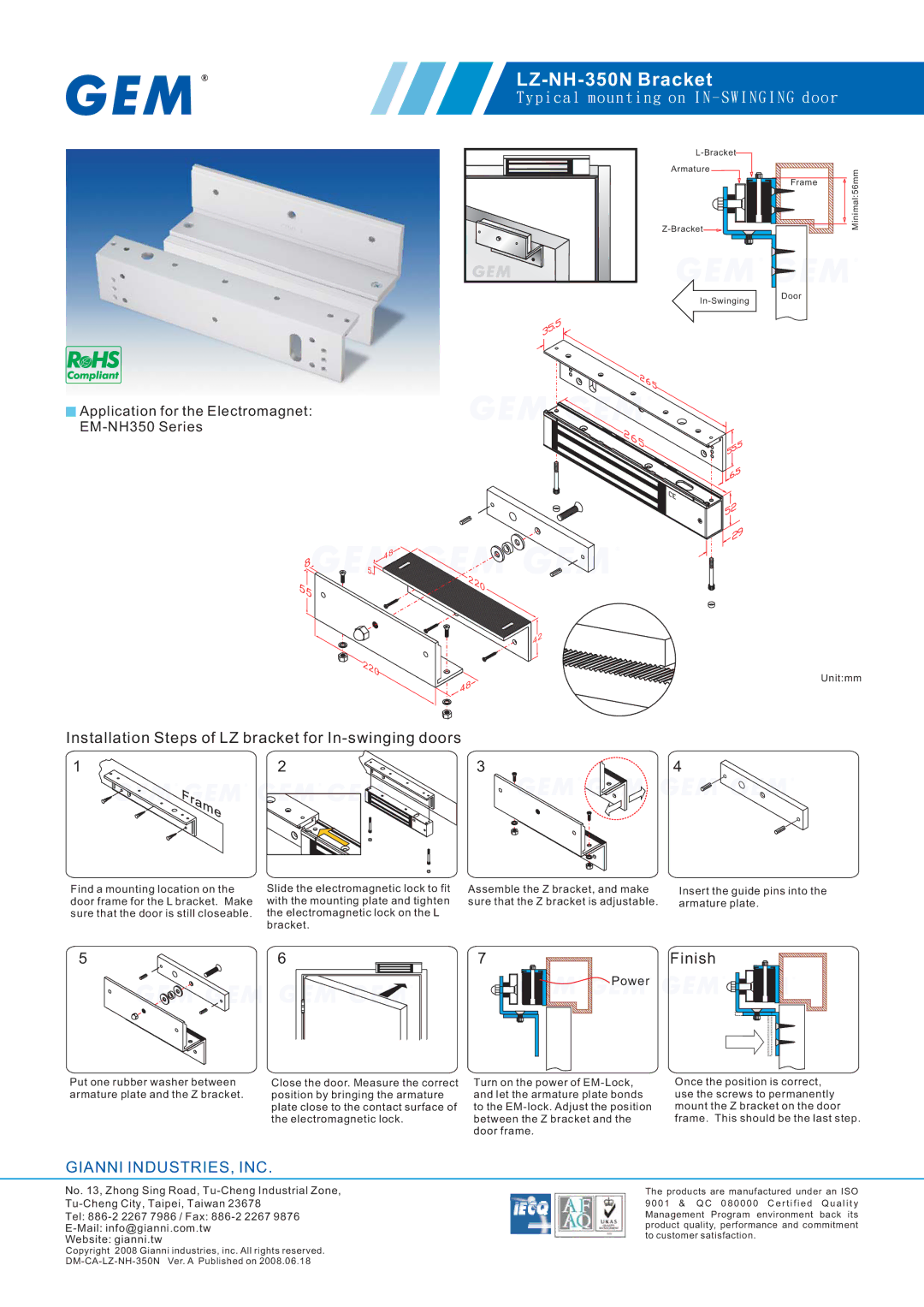

LZ-NH-350N specifications

Gianni Industries has established a formidable reputation in the field of industrial automation, and one of their standout products is the LZ-NH-350N. This exceptional machine is designed to cater to the needs of various industries, including manufacturing, packaging, and assembly.The LZ-NH-350N comes equipped with cutting-edge technologies that enhance performance and efficiency. One of its main features is the advanced servo motor system, which provides precise control over speed and torque. This allows for exceptional accuracy in tasks such as positioning and material handling. The integration of servo technology translates into reduced cycle times and improved overall productivity.

Another significant characteristic of the LZ-NH-350N is its modular design. This flexibility enables easy customization according to the specific requirements of different applications. Operators can modify components and configurations, allowing for seamless integration into existing production lines. The adaptability of the LZ-NH-350N ensures it remains relevant as industry needs evolve.

In terms of user interface, the LZ-NH-350N boasts an intuitive touchscreen control panel. This feature simplifies operation and allows even novice users to quickly understand the machine's functionalities. With easy navigation, operators can efficiently set parameters, monitor performance, and perform maintenance checks.

Safety is also a paramount consideration in the design of the LZ-NH-350N. The machine is equipped with multiple safety features, including emergency stop buttons, protective guards, and sensory equipment that detects obstructions. These features ensure a safe working environment for operators, minimizing the risk of accidents during operation.

The durability of the LZ-NH-350N is another highlight, as it is constructed from high-quality materials that endure demanding industrial conditions. This resilience not only extends the lifespan of the machine but also reduces maintenance costs for businesses.

Energy efficiency is increasingly vital in today's industrial landscape, and the LZ-NH-350N excels in this area as well. It incorporates energy-saving technologies that optimize power consumption without compromising performance. This feature not only lowers operational costs but also aligns with sustainability goals for many organizations.

In summary, the Gianni Industries LZ-NH-350N is a state-of-the-art industrial automation solution that combines advanced technology, user-friendly design, and robust safety features. Its versatility and efficiency make it an attractive option for industries aiming to enhance productivity while maintaining high safety standards.