WARNING. Avoid flying sparks and ensure they do not hit any inflammable materials, as they are very hot and could cause personal injury or a fire.

WARNING. The disc continues to turn for a few seconds even though the switch is turned off. Keep your hands well away from the moving disc.

Replacing a disc

CAUTION. Switch off the grinder and disconnect it from the power point.

1.Turn the angle grinder on to its back and press the spindle lock button (2) and rotate the spindle until it locks.

2.Insert the pins of the wrench (7) into the holes in the outer flange (8) and remove it and the old disc.

NOTE. Do not remove the inner flange (10).

WARNING. Do not use a disc marked with a lower RPM than that of the Max no load speed shown on the rating plate.

3.Clean the flanges and check the new disc.

4.Holding the angle grinder with the spindle facing upwards, check that the inner flange is on the spindle and correctly located. The two machined flat sections must face the angle grinder and locate in the appropriate position on the spindle.

5.Place the disc onto the spindle with the label facing the angle grinder. The hole in the disc should locate onto the spindle and fit firmly into the spigot section of the inner flange.

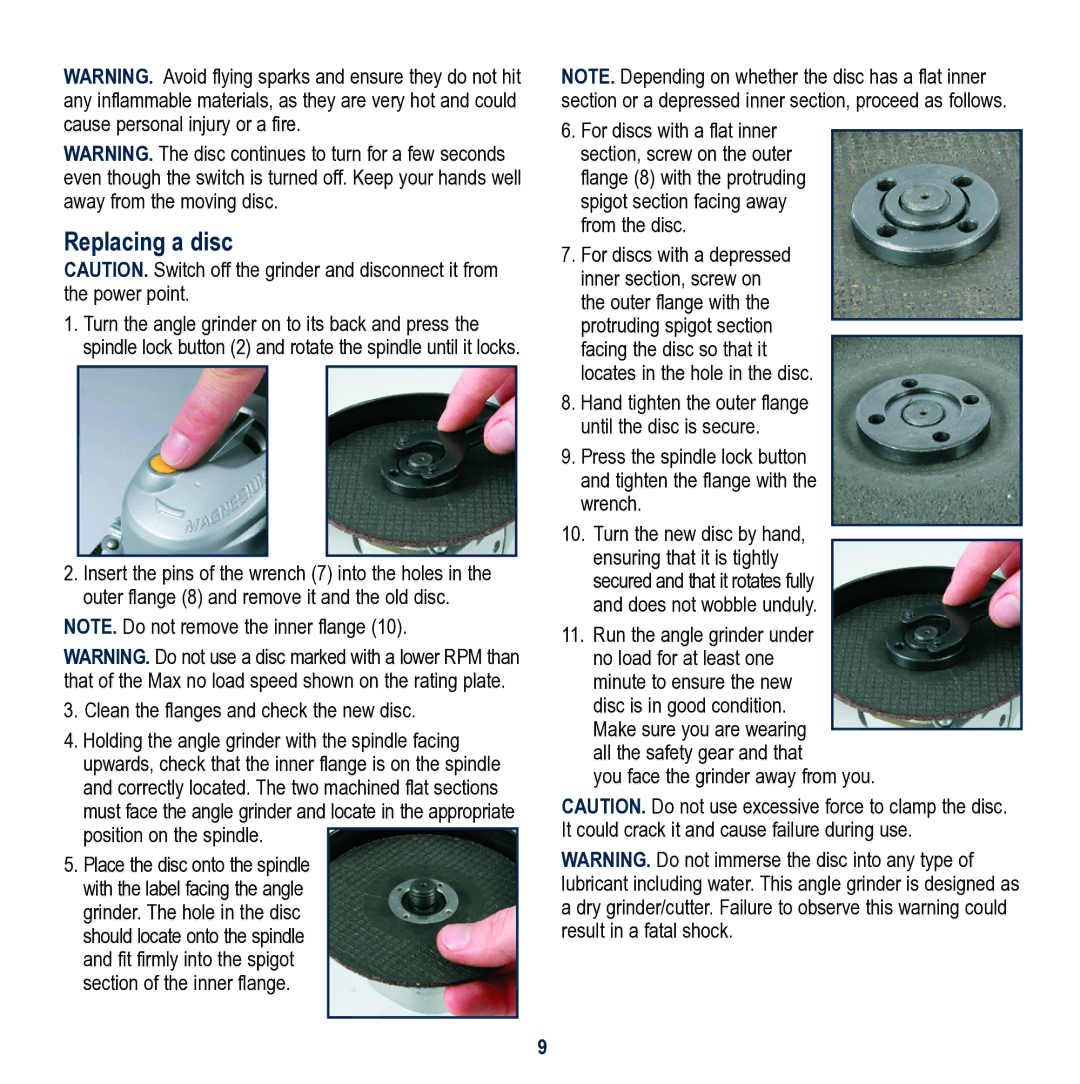

NOTE. Depending on whether the disc has a flat inner section or a depressed inner section, proceed as follows.

6.For discs with a flat inner section, screw on the outer flange (8) with the protruding spigot section facing away from the disc.

7.For discs with a depressed inner section, screw on the outer flange with the protruding spigot section facing the disc so that it locates in the hole in the disc.

8.Hand tighten the outer flange until the disc is secure.

9.Press the spindle lock button and tighten the flange with the wrench.

10. Turn the new disc by hand, ensuring that it is tightly secured and that it rotates fully and does not wobble unduly.

11.Run the angle grinder under no load for at least one minute to ensure the new disc is in good condition. Make sure you are wearing all the safety gear and that

you face the grinder away from you.

CAUTION. Do not use excessive force to clamp the disc. It could crack it and cause failure during use.

WARNING. Do not immerse the disc into any type of lubricant including water. This angle grinder is designed as a dry grinder/cutter. Failure to observe this warning could result in a fatal shock.

9