Troubleshooting

Troubleshooting

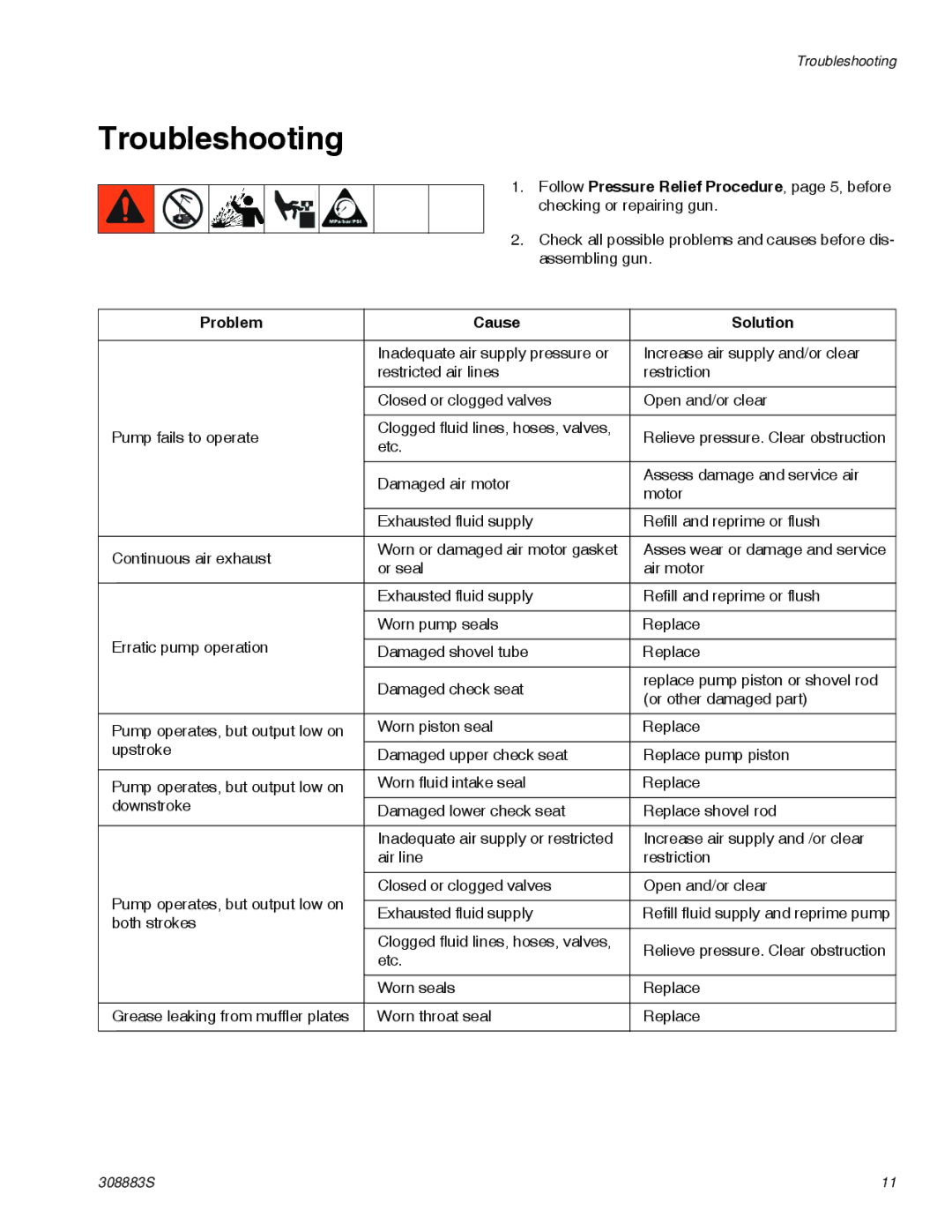

1. Follow Pressure Relief Procedure, page 5, before checking or repairing gun.

2. Check all possible problems and causes before dis- assembling gun.

Problem | Cause | Solution | |

|

|

| |

| Inadequate air supply pressure or | Increase air supply and/or clear | |

| restricted air lines | restriction | |

|

|

| |

| Closed or clogged valves | Open and/or clear | |

|

|

| |

Pump fails to operate | Clogged fluid lines, hoses, valves, | Relieve pressure. Clear obstruction | |

etc. | |||

|

| ||

|

|

| |

| Damaged air motor | Assess damage and service air | |

| motor | ||

|

| ||

|

|

| |

| Exhausted fluid supply | Refill and reprime or flush | |

|

|

| |

Continuous air exhaust | Worn or damaged air motor gasket | Asses wear or damage and service | |

or seal | air motor | ||

| |||

|

|

| |

| Exhausted fluid supply | Refill and reprime or flush | |

|

|

| |

| Worn pump seals | Replace | |

Erratic pump operation |

|

| |

Damaged shovel tube | Replace | ||

|

|

| |

| Damaged check seat | replace pump piston or shovel rod | |

| (or other damaged part) | ||

|

| ||

|

|

| |

Pump operates, but output low on | Worn piston seal | Replace | |

upstroke | Damaged upper check seat | Replace pump piston | |

|

|

| |

Pump operates, but output low on | Worn fluid intake seal | Replace | |

downstroke | Damaged lower check seat | Replace shovel rod | |

|

|

| |

| Inadequate air supply or restricted | Increase air supply and /or clear | |

| air line | restriction | |

|

|

| |

Pump operates, but output low on | Closed or clogged valves | Open and/or clear | |

|

| ||

Exhausted fluid supply | Refill fluid supply and reprime pump | ||

both strokes | |||

|

| ||

| Clogged fluid lines, hoses, valves, | Relieve pressure. Clear obstruction | |

| etc. | ||

|

| ||

|

|

| |

| Worn seals | Replace | |

|

|

| |

Grease leaking from muffler plates | Worn throat seal | Replace | |

|

|

|

308883S | 11 |