Setup

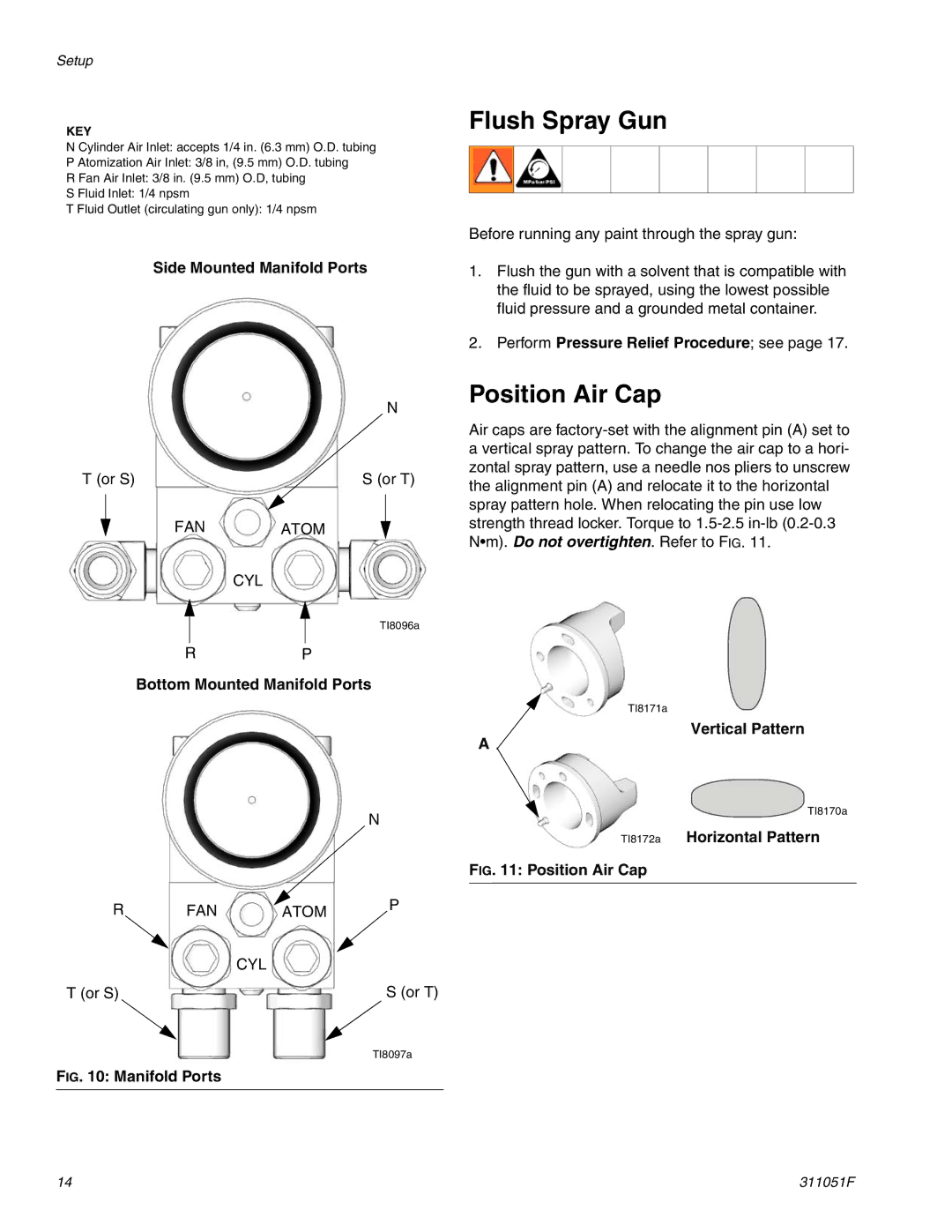

KEY

N Cylinder Air Inlet: accepts 1/4 in. (6.3 mm) O.D. tubing

P Atomization Air Inlet: 3/8 in, (9.5 mm) O.D. tubing

R Fan Air Inlet: 3/8 in. (9.5 mm) O.D, tubing

S Fluid Inlet: 1/4 npsm

T Fluid Outlet (circulating gun only): 1/4 npsm

Side Mounted Manifold Ports

N

T (or S) | S (or T) |

FAN ATOM

CYL

TI8096a

RP

Bottom Mounted Manifold Ports

N

R | FAN | ATOM | P |

| |||

|

| CYL |

|

T (or S) |

|

| S (or T) |

|

|

| TI8097a |

FIG. 10: Manifold Ports

Flush Spray Gun

Before running any paint through the spray gun:

1.Flush the gun with a solvent that is compatible with the fluid to be sprayed, using the lowest possible fluid pressure and a grounded metal container.

2.Perform Pressure Relief Procedure; see page 17.

Position Air Cap

Air caps are

TI8171a

Vertical Pattern

A

TI8170a

TI8172a Horizontal Pattern

FIG. 11: Position Air Cap

14 | 311051F |