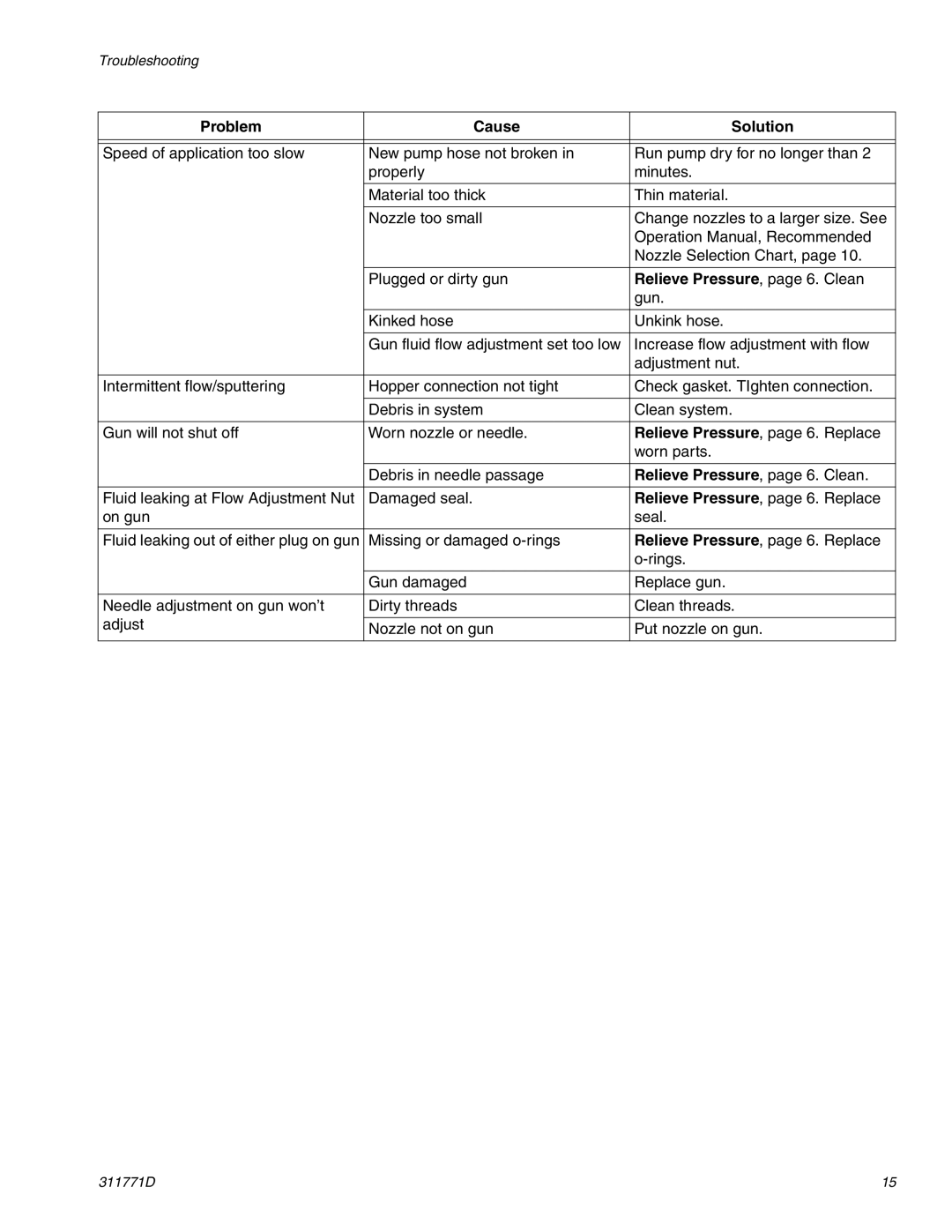

Troubleshooting

Problem | Cause | Solution | |

|

|

| |

|

|

| |

Speed of application too slow | New pump hose not broken in | Run pump dry for no longer than 2 | |

| properly | minutes. | |

|

|

| |

| Material too thick | Thin material. | |

|

|

| |

| Nozzle too small | Change nozzles to a larger size. See | |

|

| Operation Manual, Recommended | |

|

| Nozzle Selection Chart, page 10. | |

|

|

| |

| Plugged or dirty gun | Relieve Pressure, page 6. Clean | |

|

| gun. | |

|

|

| |

| Kinked hose | Unkink hose. | |

|

|

| |

| Gun fluid flow adjustment set too low | Increase flow adjustment with flow | |

|

| adjustment nut. | |

|

|

| |

Intermittent flow/sputtering | Hopper connection not tight | Check gasket. TIghten connection. | |

|

|

| |

| Debris in system | Clean system. | |

|

|

| |

Gun will not shut off | Worn nozzle or needle. | Relieve Pressure, page 6. Replace | |

|

| worn parts. | |

|

|

| |

| Debris in needle passage | Relieve Pressure, page 6. Clean. | |

|

|

| |

Fluid leaking at Flow Adjustment Nut | Damaged seal. | Relieve Pressure, page 6. Replace | |

on gun |

| seal. | |

|

|

| |

Fluid leaking out of either plug on gun | Missing or damaged | Relieve Pressure, page 6. Replace | |

|

| ||

|

|

| |

| Gun damaged | Replace gun. | |

|

|

| |

Needle adjustment on gun won’t | Dirty threads | Clean threads. | |

adjust |

|

| |

Nozzle not on gun | Put nozzle on gun. | ||

| |||

|

|

|

311771D | 15 |