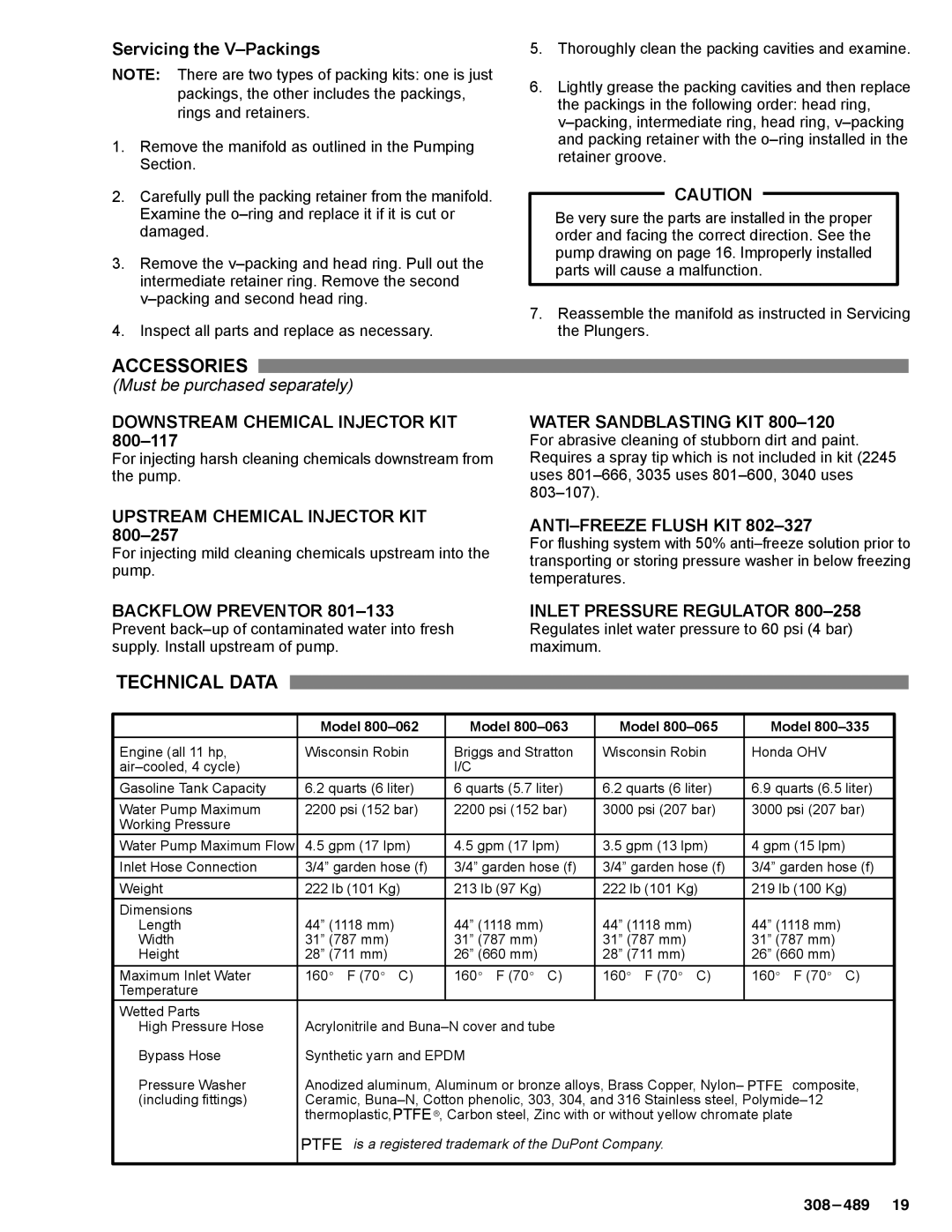

2245, 3035, 800-335, 800-065, 800-062 specifications

Graco Inc. has made significant strides in the manufacturing of fluid handling systems and equipment, positioning itself as a leader in the industry. Among their well-regarded products are the models 800-062, 308-501, 800-065, 800-335, and 3035. Each of these models comes with unique features and technologies that cater to various industrial applications.The Graco 800-062 model is known for its reliability and efficiency in fluid transfer applications. It features a durable construction that withstands tough job site conditions. This model is equipped with advanced pneumatic technology, allowing for controlled fluid dispensing, which minimizes waste and enhances precision. Graco's attention to detail in ergonomics also enables operators to handle the device with comfort, reducing user fatigue during prolonged use.

The 308-501 model excels in its versatility, providing multiple output options to meet different operational needs. Its modular design allows for easy upgrades and maintenance. A standout characteristic of this model is its integrated filtration system, which ensures that the fluid remains contaminant-free, ultimately improving the quality of the application.

Moving on to the 800-065 model, this equipment is particularly known for its high flow rates and heavy-duty performance. Ideal for high-volume applications, it combines advanced hydraulic technology with a robust build, making it suitable for both indoor and outdoor environments. The automatic pressure regulation feature enhances its operational safety and extends the service life of the equipment.

The Graco 800-335 model stands out for its compact design, making it a perfect choice for workspaces with limited space. Despite its small footprint, it doesn't compromise on performance. The user-friendly interface allows for easy adjustments, and the model is equipped with low noise technology, making it ideal for noise-sensitive environments.

Finally, the Graco 3035 model is designed for precision and accuracy in fluid dispensing processes. It features intuitive controls and a state-of-the-art monitoring system, allowing for real-time feedback on fluid levels and pressure. An automatic shut-off feature ensures safety and prevents overfilling or accidental spills.

In summary, Graco Inc.'s models 800-062, 308-501, 800-065, 800-335, and 3035 represent a blend of innovation, durability, and user-centered design, making them vital tools in various industrial applications ranging from construction to manufacturing. These models not only enhance productivity but also ensure optimal operational safety, meeting the demands of a rapidly evolving industry.