10 309489

MaintenanceLubrication

If your system includes an automatic air line lubricator,

adjust the lubricator as instructed in the separate

instruction manual.

For manual lubrication, each day, remove the air inlet

hose and place 12 to 15 drops of high quality, light

motor oil in the inlet. Reattach the hose and turn on the

air to blow the oil into the motor.

Throat Packing Adjustment

WARNING

Toreduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 8.

Once a week, or after each 40 hours of operation,

check the tightness of the throat packing nut. It should

be tight enough to stop leakage, but no tighter.

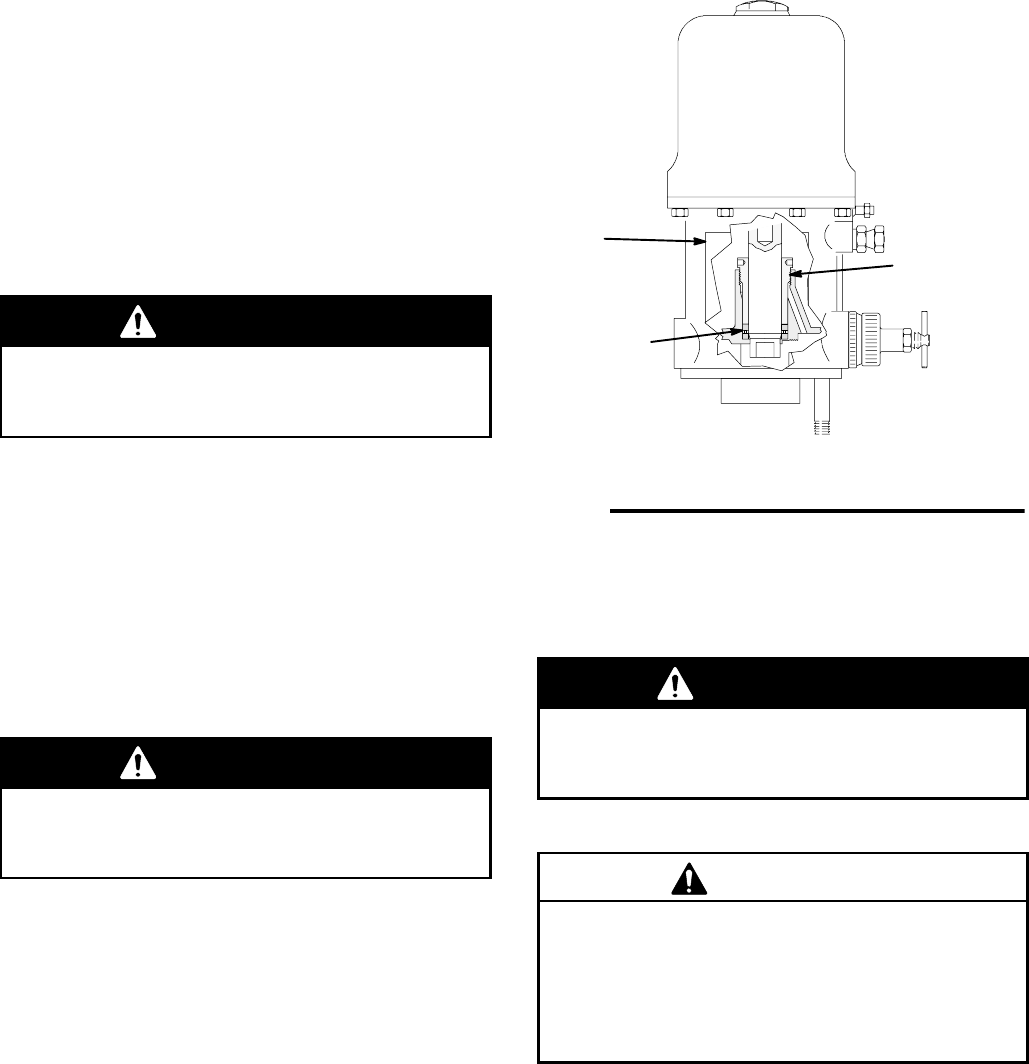

Tocheck, first relieve the p ressure. Then, remove the

identification plate (M) from the motor. Using a spanner

wrench or a 0.22 in (5.6 mm) diameter rod, adjust the

nut. Reinstall the identification plate before operating

the pump. See Fig. 3.

Flushing

WARNING

Toreduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 8.

Toreduce the risk of injection injury, static sparking, or

splashing in the eyes or on the skin, relieve the pres-

sure. Then, remove the spray tip (spray guns or spray

valves only) before flushing. Hold a metal part of the

gun/valve firmly to the side of a grounded metal pail

and use the lowest possible fluid pressure during

flushing.

Fig. 3

06701

MPacking

Nut

Leather

Throat

Packings

Corrosion Protection

WARNING

Toreduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 8.

C

A

UTION

Water, or even moist air, can cause your pump to

corrode. Tohelp prevent corrosion, never leave the

pump filled with water-based fluid or air. After normal

flushing, flush the pump again with mineral spirits or

oil-based solvent, and relieve the pressure. This

leaves the mineral spirits in the pump.