3245, 801-644, 800-066 specifications

Graco Inc. is a leading manufacturer in the fluid and paint application equipment industry, delivering innovative solutions for a wide range of applications. Among its notable products are models 800-066, 3245, and 801-644, each designed to meet specific operational needs while providing efficiency and reliability.The Graco Inc. 800-066 is well-regarded for its versatility in paint application. It is ideal for both professional and DIY projects, featuring an adjustable pressure setting that allows users to tailor the spray output according to the material being used. This model also boasts a high-efficiency airless pump that ensures consistent coverage, reducing the time needed for painting large surfaces. The lightweight construction and compact design make it easy to navigate around job sites, while the QuickChange Piston System simplifies maintenance and enhances longevity.

The 3245 model represents Graco’s commitment to ergonomics and ease of use. This airless sprayer is engineered to minimize user fatigue, featuring a comfortable grip and a well-balanced design. The 3245 is equipped with advanced filtration technology that helps prevent clogging and ensures a smooth spray pattern, thus enhancing overall efficiency. This makes it an excellent choice for extensive projects requiring continuous operation, such as commercial painting or large-scale renovations.

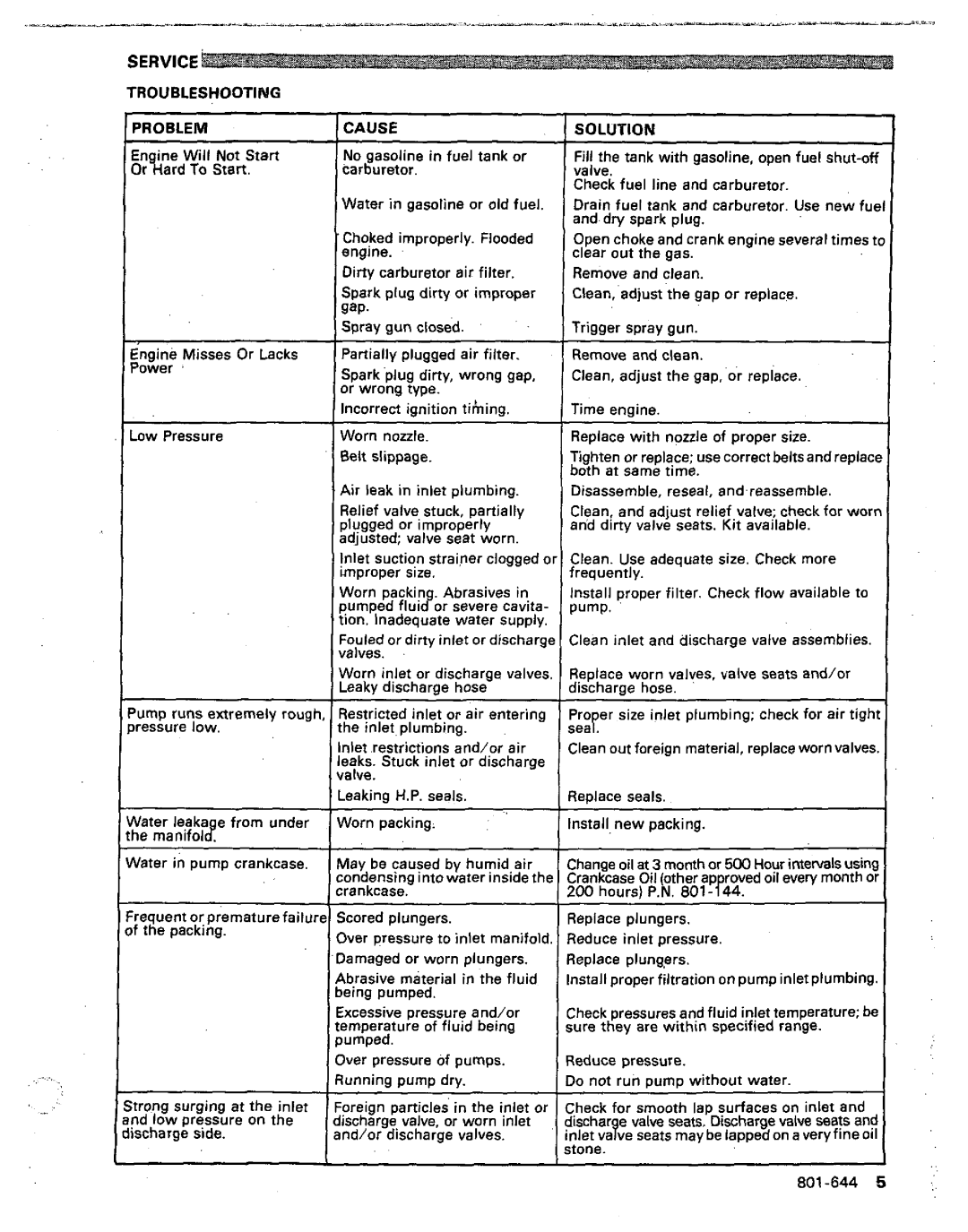

Graco’s model 801-644 stands out with its robust build and high-performance capabilities. It is designed to handle heavy-duty applications, suitable for professionals who demand reliability and durability in their equipment. The 801-644 incorporates a ProConnect system that allows for quick and easy component replacement without the need for specialized tools. This not only saves time during maintenance but also minimizes downtime on critical projects. Its high-output pump and precise nozzle design contribute to optimal paint atomization, resulting in a flawless finish.

In summary, Graco Inc. models 800-066, 3245, and 801-644 demonstrate the company’s leadership in the fluid application market. Their focus on user-friendly design, advanced technology, and durable construction ensures that users can rely on these tools for efficient and effective application of paints and coatings. Whether for home improvement, commercial use, or industrial applications, Graco’s innovative solutions continue to set the standard in the industry.