GC-1412 specifications

Graco Inc., a leading manufacturer in fluid management solutions, has made significant strides in the industrial sector with its innovative products. One such product, the Graco GC-1412, is a versatile and reliable solution for various material handling and fluid dispensing tasks. This equipment is particularly appreciated for its efficiency, durability, and advanced technologies that ensure smooth operation.The GC-1412 model is designed specifically for handling a wide range of liquids, including coatings, adhesives, and other viscous materials, making it an ideal choice for industries such as manufacturing, construction, and automotive. It features a powerful, high-output pump that provides consistent pressure, ensuring that material is dispensed evenly, which is critical for achieving quality results.

One of the main features of the Graco GC-1412 is its robust construction. Built with high-quality materials, this unit is engineered to withstand the rigors of industrial environments. It comes equipped with a protective enclosure that shields critical components from damage, and its compact design allows for easy transportation and storage.

In terms of technology, the GC-1412 leverages state-of-the-art control systems that simplify operation and enhance user experience. The integrated digital display provides real-time feedback on pump operation, including pressure levels and fluid flow rates. This feature not only aids in monitoring performance but also assists in troubleshooting any potential issues before they escalate.

Another key characteristic of the Graco GC-1412 is its easy maintenance profile. The unit is designed with accessibility in mind, allowing operators to perform routine maintenance quickly without extensive downtime. This focus on ease of maintenance reduces operational interruptions and prolongs the lifespan of the equipment.

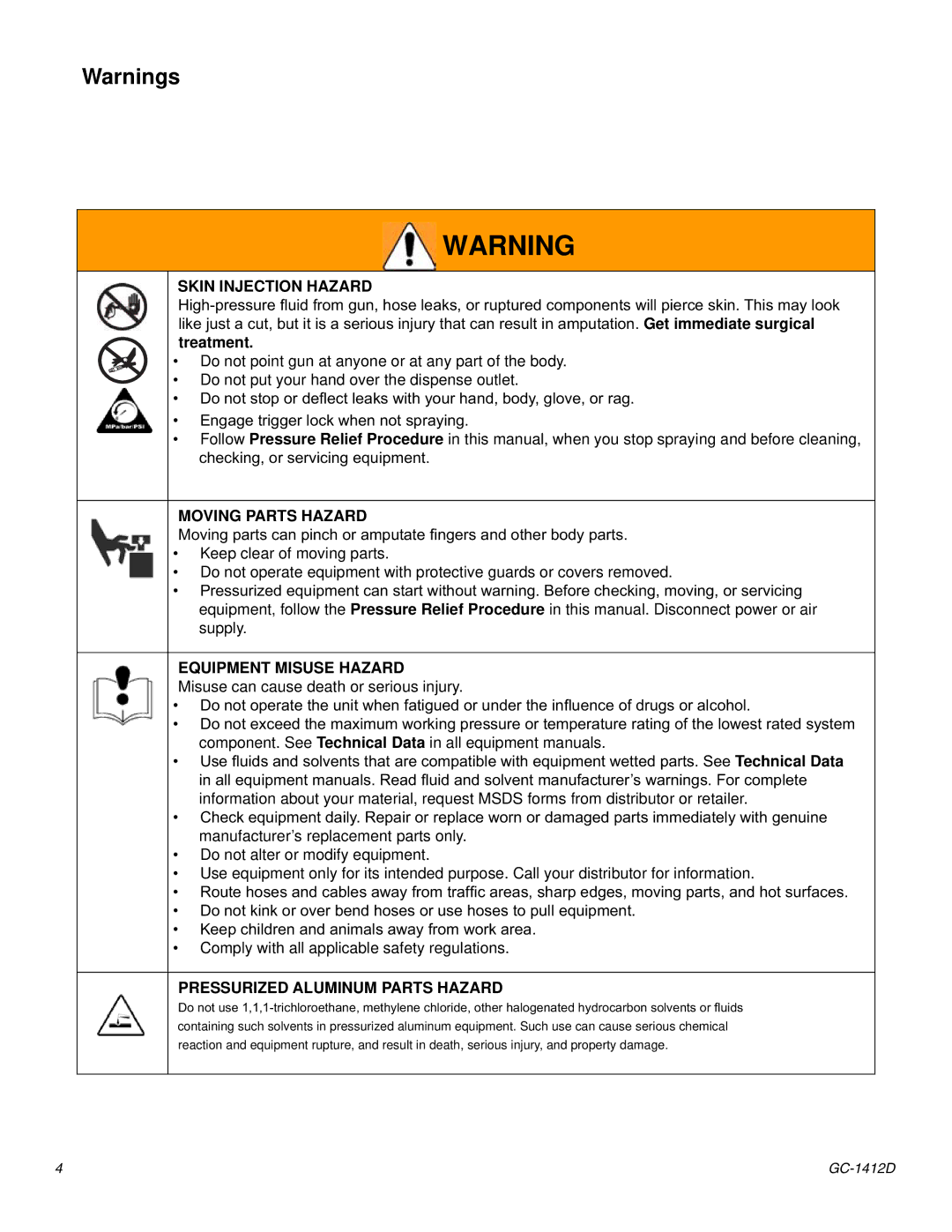

Moreover, the system is equipped with safety features, such as pressure relief valves and fail-safe mechanisms that help protect both the operator and the equipment. These safeguards are essential in preventing accidents and ensuring compliance with industry standards.

In conclusion, the Graco GC-1412 stands out as a robust and efficient solution for fluid management tasks. With its durable construction, advanced technology, and user-friendly design, it fulfills the needs of various industries while ensuring safety and reliability. Whether for professional or heavy industrial use, the GC-1412 is a dependable choice that provides high performance and value.