Greenheck Product Application Guide

Writing the Bearing Specification

Basic Rating Life, L10 is a useful tool when specifying a given level of bearing construction. When required to provide a given L10 life, all equipment manufacturers must supply the same capacity bearing for a given RPM and shaft diameter. Also, an 80,000 hour L10 bearing will have a theoretical life twice as long as a 40,000 hour L10 bearing and hence will last longer in the field.

Here’s Greenheck’s recommendation for a typical bearing specification:

“Bearings shall be air handling quality, heavy duty grease lubricated, ball or roller type. Bearings shall be selected for a Basic Rating Life, (L10) of 80,000 hours at maximum operating speed and horsepower for each construction level.” (Air handling quality means the bearings meet the requirements for use in air handling applications; high speeds, long life and quiet operation. All bearings are 100% tested for excessive noise levels and bore dimensions are verified to be within tolerances.)

Note: If all the fan products you are specifying are from the Greenheck Fan & Vent catalog, you can specify L10 100,000 hour life bearings at no extra charge.

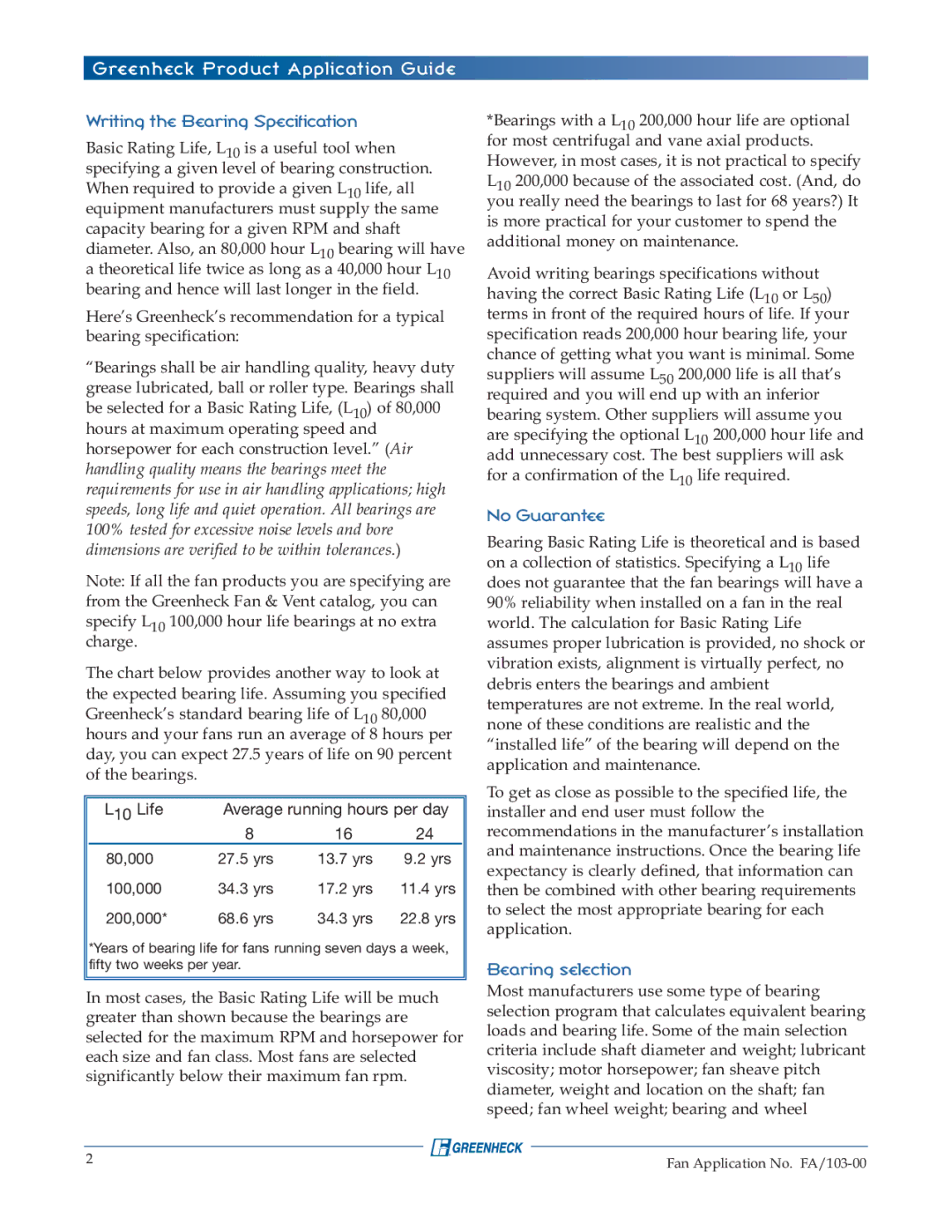

The chart below provides another way to look at the expected bearing life. Assuming you specified Greenheck’s standard bearing life of L10 80,000 hours and your fans run an average of 8 hours per day, you can expect 27.5 years of life on 90 percent of the bearings.

L10 Life | Average running hours per day | ||

| 8 | 16 | 24 |

80,000 | 27.5 yrs | 13.7 yrs | 9.2 yrs |

100,000 | 34.3 yrs | 17.2 yrs | 11.4 yrs |

200,000* | 68.6 yrs | 34.3 yrs | 22.8 yrs |

*Years of bearing life for fans running seven days a week, fifty two weeks per year.

In most cases, the Basic Rating Life will be much greater than shown because the bearings are selected for the maximum RPM and horsepower for each size and fan class. Most fans are selected significantly below their maximum fan rpm.

*Bearings with a L10 200,000 hour life are optional for most centrifugal and vane axial products. However, in most cases, it is not practical to specify L10 200,000 because of the associated cost. (And, do you really need the bearings to last for 68 years?) It is more practical for your customer to spend the additional money on maintenance.

Avoid writing bearings specifications without having the correct Basic Rating Life (L10 or L50) terms in front of the required hours of life. If your specification reads 200,000 hour bearing life, your chance of getting what you want is minimal. Some suppliers will assume L50 200,000 life is all that’s required and you will end up with an inferior bearing system. Other suppliers will assume you are specifying the optional L10 200,000 hour life and add unnecessary cost. The best suppliers will ask for a confirmation of the L10 life required.

No Guarantee

Bearing Basic Rating Life is theoretical and is based on a collection of statistics. Specifying a L10 life does not guarantee that the fan bearings will have a 90% reliability when installed on a fan in the real world. The calculation for Basic Rating Life assumes proper lubrication is provided, no shock or vibration exists, alignment is virtually perfect, no debris enters the bearings and ambient temperatures are not extreme. In the real world, none of these conditions are realistic and the “installed life” of the bearing will depend on the application and maintenance.

To get as close as possible to the specified life, the installer and end user must follow the recommendations in the manufacturer’s installation and maintenance instructions. Once the bearing life expectancy is clearly defined, that information can then be combined with other bearing requirements to select the most appropriate bearing for each application.

Bearing selection

Most manufacturers use some type of bearing selection program that calculates equivalent bearing loads and bearing life. Some of the main selection criteria include shaft diameter and weight; lubricant viscosity; motor horsepower; fan sheave pitch diameter, weight and location on the shaft; fan speed; fan wheel weight; bearing and wheel

2 | ® |

| Fan Application No. |