UL 762 specifications

The Greenheck Fan UL 762 is a prominent solution in the industry for commercial kitchen ventilation systems. Specifically designed for exhausting grease-laden air, these fans play a crucial role in maintaining air quality and safety in restaurants and food preparation environments. The UL 762 certification indicates that the fan meets the rigorous safety standards established for commercial cooking applications, making it an ideal choice for kitchens seeking reliability and effectiveness in ventilation.One of the main features of the Greenheck UL 762 fan is its energy efficiency. The fan's motors are designed to minimize energy consumption while maintaining high airflow rates. This not only reduces operational costs but also aligns with the growing demand for sustainable practices in commercial kitchens. Additionally, these fans are equipped with advanced motor technologies such as ECM (electronically commutated motor) which enhances operational efficiency and provides precise control over airflow.

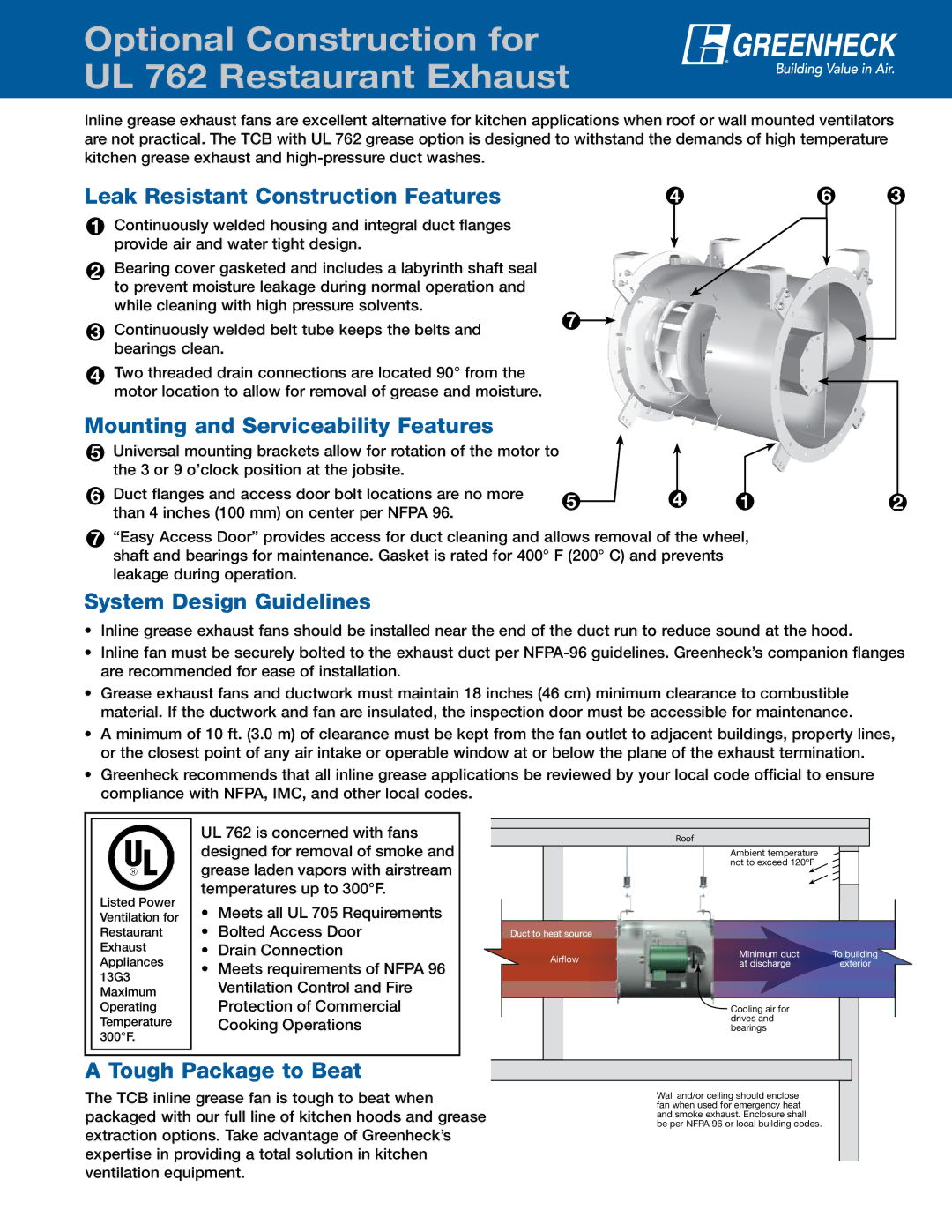

Durability is another hallmark of the Greenheck UL 762 fan. Constructed with high-quality materials, these fans are built to withstand the harsh conditions of a commercial kitchen, including exposure to grease, heat, and humidity. The housing's robust design prevents leaks and corrosion, ensuring longevity and reliable performance over time. Moreover, the fans feature a self-cleaning design that allows for easier maintenance, reducing downtime and labor costs associated with upkeep.

Noise reduction is a vital consideration in kitchen environments, and the Greenheck UL 762 addresses this with quiet operation technologies. The fan's aerodynamic design minimizes turbulence, resulting in lower sound levels without sacrificing performance. This feature enhances the comfort of kitchen staff while allowing for a more pleasant dining atmosphere for patrons.

Another significant characteristic of the Greenheck UL 762 fan is its versatility. Available in various sizes and configurations, these fans can be tailored to meet the specific needs of different kitchen layouts and exhaust requirements. This flexibility ensures that restaurant owners can achieve optimal air management while complying with local building codes and health regulations.

In summary, the Greenheck Fan UL 762 exemplifies the integration of modern technology and practical design in commercial kitchen ventilation. With its energy-efficient motors, durable construction, noise reduction capabilities, and versatile options, the UL 762 is a top choice for operators looking to enhance their kitchen environment while ensuring safety and compliance with industry standards. Ultimately, investing in a Greenheck UL 762 fan not only improves air quality but also contributes to a safer and more efficient commercial kitchen operation.