SECTION 4: ASSEMBLY

Stand Assembly

Most of your Planer/Moulder has been assem- bled at the factory. The few remaining pieces should go together quickly and easily. With just a few simple hand tools, completion of your new Planer/Moulder is quite straight forward.

We have organized the assembly process into steps. Please follow them in sequence.

Caution: All

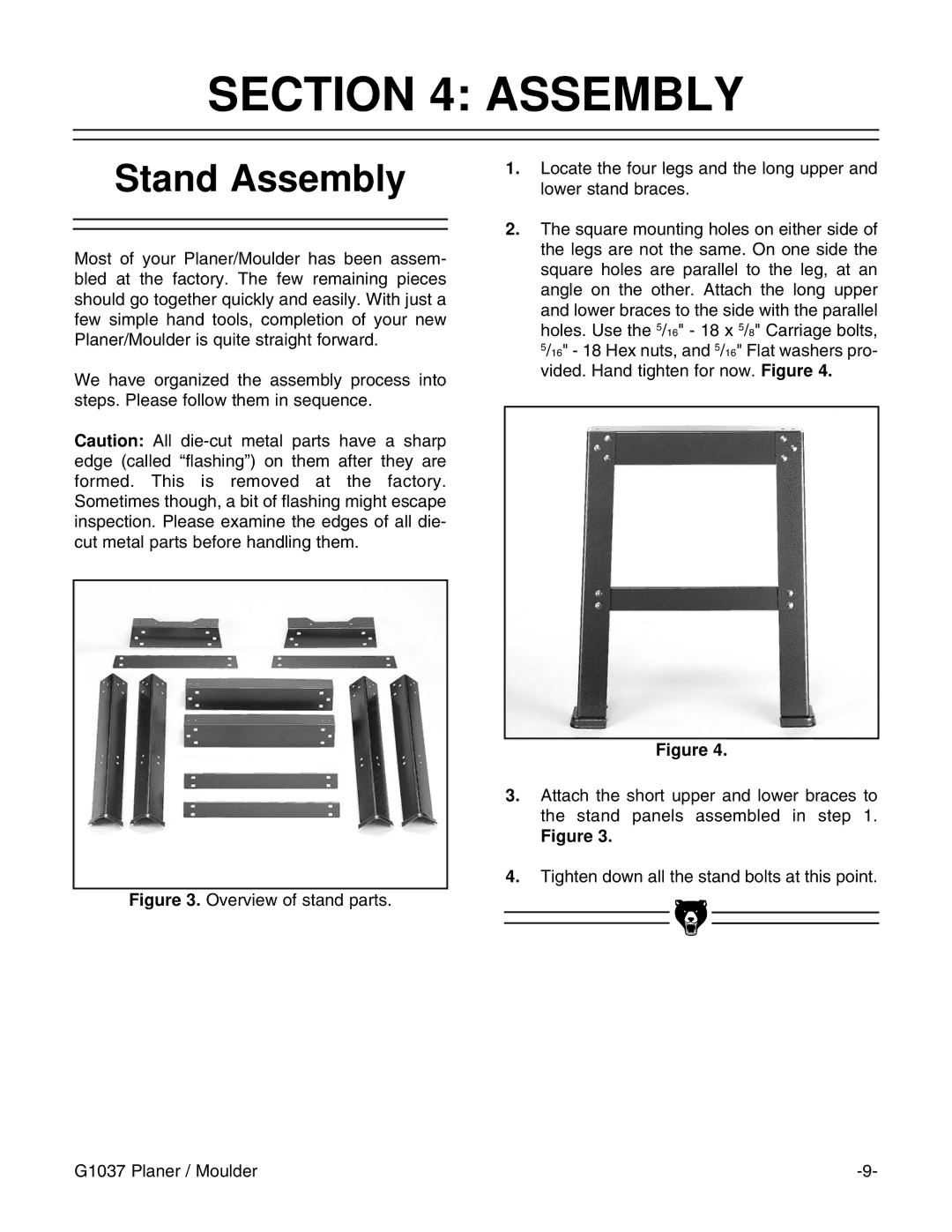

Figure 3. Overview of stand parts.

1.Locate the four legs and the long upper and lower stand braces.

2.The square mounting holes on either side of the legs are not the same. On one side the square holes are parallel to the leg, at an angle on the other. Attach the long upper and lower braces to the side with the parallel holes. Use the 5/16" - 18 x 5/8" Carriage bolts, 5/16" - 18 Hex nuts, and 5/16" Flat washers pro- vided. Hand tighten for now. Figure 4.

Figure 4.

3.Attach the short upper and lower braces to the stand panels assembled in step 1.

Figure 3.

4.Tighten down all the stand bolts at this point.

G1037 Planer / Moulder |