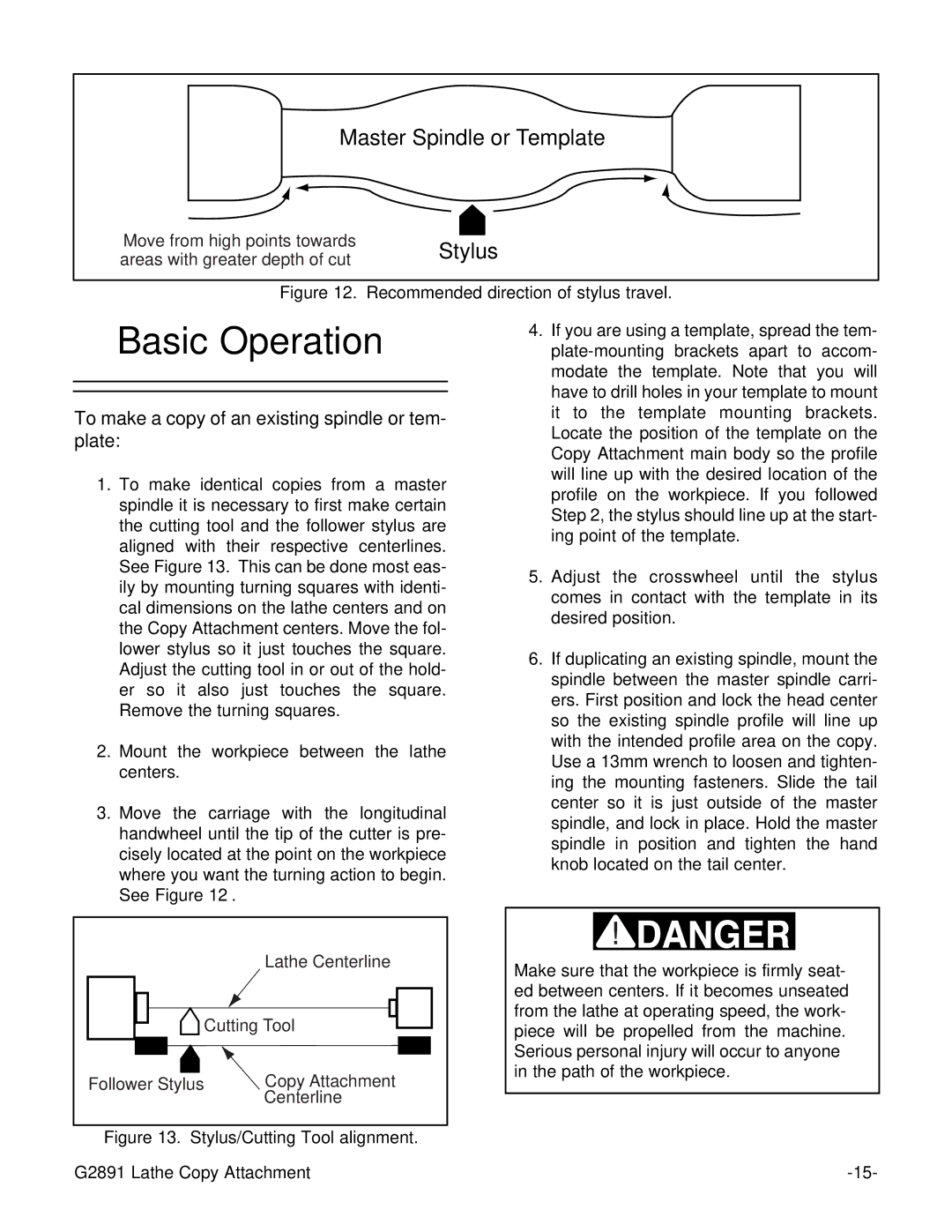

Master Spindle or Template

Move from high points towards areas with greater depth of cut

Stylus

Figure 12. Recommended direction of stylus travel.

Basic Operation

To make a copy of an existing spindle or tem- plate:

1.To make identical copies from a master spindle it is necessary to first make certain the cutting tool and the follower stylus are aligned with their respective centerlines. See Figure 13. This can be done most eas- ily by mounting turning squares with identi- cal dimensions on the lathe centers and on the Copy Attachment centers. Move the fol- lower stylus so it just touches the square. Adjust the cutting tool in or out of the hold- er so it also just touches the square. Remove the turning squares.

2.Mount the workpiece between the lathe centers.

3.Move the carriage with the longitudinal handwheel until the tip of the cutter is pre- cisely located at the point on the workpiece where you want the turning action to begin. See Figure 12.

4.If you are using a template, spread the tem-

5.Adjust the crosswheel until the stylus comes in contact with the template in its desired position.

6.If duplicating an existing spindle, mount the spindle between the master spindle carri- ers. First position and lock the head center so the existing spindle profile will line up with the intended profile area on the copy. Use a 13mm wrench to loosen and tighten- ing the mounting fasteners. Slide the tail center so it is just outside of the master spindle, and lock in place. Hold the master spindle in position and tighten the hand knob located on the tail center.

Lathe Centerline

Cutting Tool | |

Follower Stylus | Copy Attachment |

| Centerline |

Figure 13. Stylus/Cutting Tool alignment.

G2891 Lathe Copy Attachment

Make sure that the workpiece is firmly seat- ed between centers. If it becomes unseated from the lathe at operating speed, the work- piece will be propelled from the machine. Serious personal injury will occur to anyone in the path of the workpiece.