|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

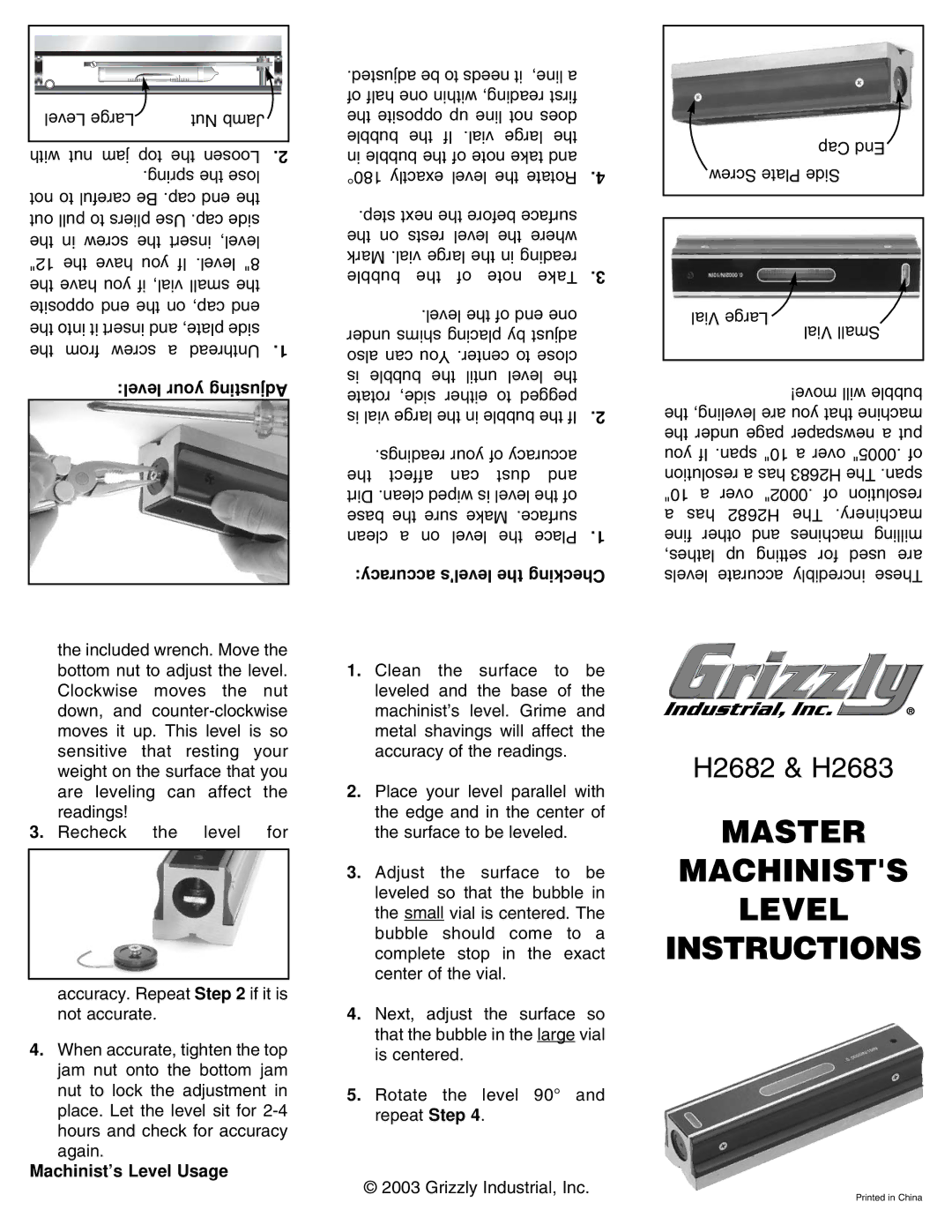

| Level Large | Nut Jamb |

|

| ||||

|

|

|

|

|

|

|

|

|

with nut jam top the Loosen | .2 | |||||||

|

|

| .spring the lose |

|

| |||

not to careful Be .cap end the |

|

| ||||||

out pull to pliers Use .cap side |

|

| ||||||

the in screw the insert level, |

|

| ||||||

12" the have you If .level 8" |

|

| ||||||

the have you if vial, small the |

|

| ||||||

opposite end the on cap, end |

|

| ||||||

the into it insert and plate, side |

|

| ||||||

the from screw a | Unthread | .1 | ||||||

|

| level: your Adjusting | ||||||

|

|

|

|

|

|

|

|

|

.adjusted be to needs it | line, a |

| ||||

of half one within reading, first |

| |||||

the opposite up line not does |

| |||||

bubble | the | If .vial large the |

| |||

in bubble the of note take and |

| |||||

180° exactly level the Rotate | .4 | |||||

.step next the before surface |

| |||||

the on rests level the where |

| |||||

Mark .vial large the in reading |

| |||||

bubble | the | of | note | Take | .3 | |

|

| .level the of end one |

| |||

under shims placing by adjust |

| |||||

also can You .center to close |

| |||||

is bubble the until level the |

| |||||

rotate side, either to pegged |

| |||||

is vial large the in bubble the If | .2 | |||||

.readings your of accuracy |

| |||||

the | affect | can | dust | and |

| |

Dirt .clean wiped is level the of |

| |||||

base the sure Make .surface |

| |||||

clean | a on level the Place .1 | |||||

accuracy: level's the Checking | ||||||

Cap End

Screw Plate Side

Vial Large![]() Vial Small

Vial Small

move! will bubble the leveling, are you that machine the under page newspaper a put you If .span 10" a over 0005". of resolution a has H2683 The .span 10" a over 0002". of resolution a has H2682 The .machinery fine other and machines milling lathes, up setting for used are levels accurate incredibly These

the included wrench. Move the bottom nut to adjust the level. Clockwise moves the nut down, and

3. Recheck the level for

accuracy. Repeat Step 2 if it is not accurate.

4.When accurate, tighten the top jam nut onto the bottom jam nut to lock the adjustment in place. Let the level sit for

again.

Machinist’s Level Usage

1.Clean the surface to be leveled and the base of the machinist’s level. Grime and metal shavings will affect the accuracy of the readings.

2.Place your level parallel with the edge and in the center of the surface to be leveled.

3.Adjust the surface to be leveled so that the bubble in the small vial is centered. The bubble should come to a complete stop in the exact center of the vial.

4.Next, adjust the surface so that the bubble in the large vial is centered.

5.Rotate the level 90° and repeat Step 4.

© 2003 Grizzly Industrial, Inc.

H2682 & H2683

MASTER

MACHINIST'S

LEVEL

INSTRUCTIONS

Printed in China