Compressed Air System

The Model H5571 is designed to be oper- ated at

maximum operating pressure!

Before you use your new nailer, regulate the air pressure on your air compressor to barely over the minimum psi for your nail- er. Increase air pressure only if needed.

Many pneumatic tools benefit from an in- line filter/lubricator/regulator unit. Using this unit protects your tool from damaging water

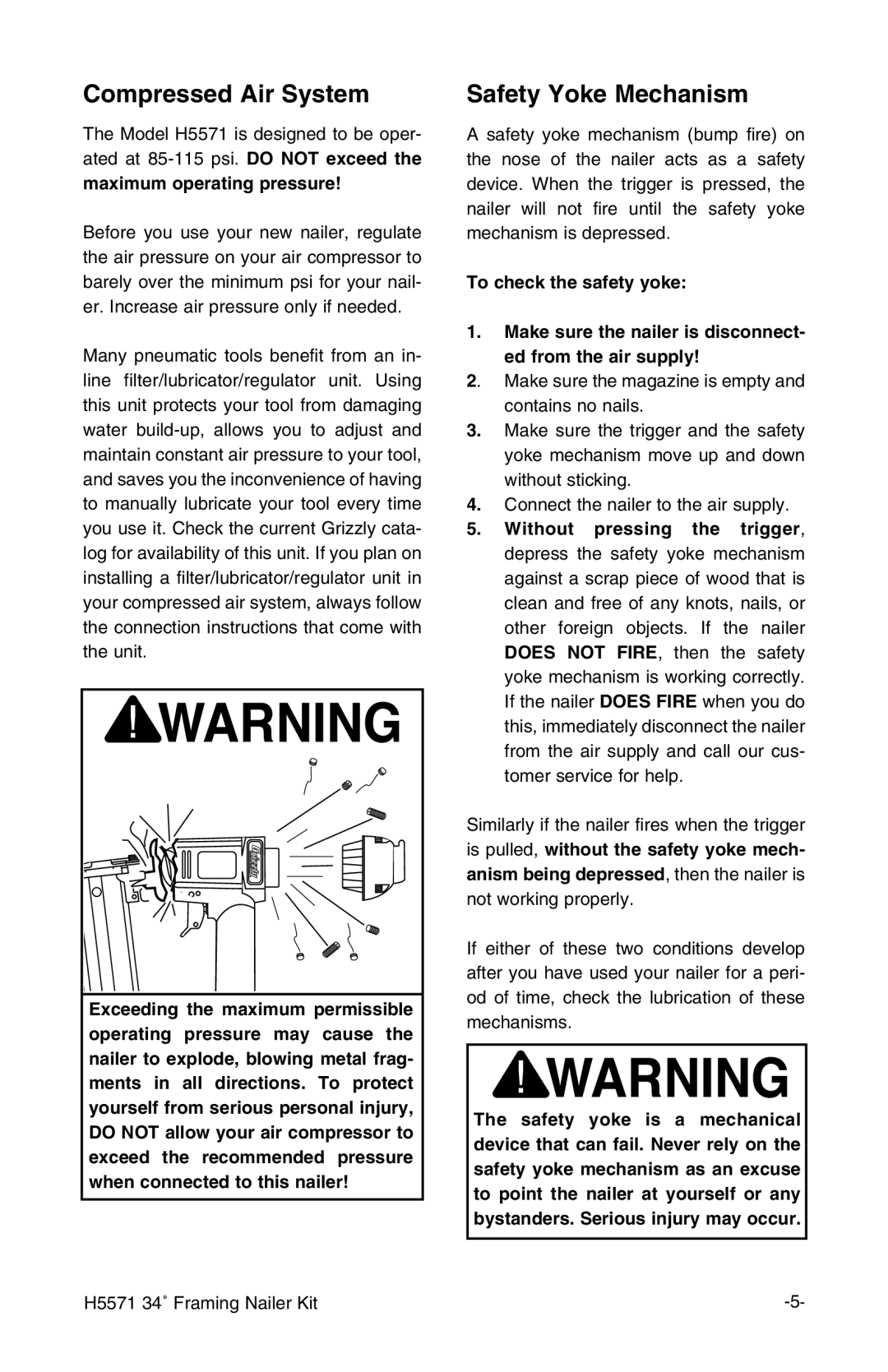

Exceeding the maximum permissible operating pressure may cause the nailer to explode, blowing metal frag- ments in all directions. To protect yourself from serious personal injury, DO NOT allow your air compressor to exceed the recommended pressure when connected to this nailer!

Safety Yoke Mechanism

A safety yoke mechanism (bump fire) on the nose of the nailer acts as a safety device. When the trigger is pressed, the nailer will not fire until the safety yoke mechanism is depressed.

To check the safety yoke:

1.Make sure the nailer is disconnect- ed from the air supply!

2. Make sure the magazine is empty and contains no nails.

3.Make sure the trigger and the safety yoke mechanism move up and down without sticking.

4.Connect the nailer to the air supply.

5.Without pressing the trigger, depress the safety yoke mechanism against a scrap piece of wood that is clean and free of any knots, nails, or other foreign objects. If the nailer DOES NOT FIRE, then the safety yoke mechanism is working correctly. If the nailer DOES FIRE when you do this, immediately disconnect the nailer from the air supply and call our cus- tomer service for help.

Similarly if the nailer fires when the trigger is pulled, without the safety yoke mech- anism being depressed, then the nailer is not working properly.

If either of these two conditions develop after you have used your nailer for a peri- od of time, check the lubrication of these mechanisms.

The safety yoke is a mechanical device that can fail. Never rely on the safety yoke mechanism as an excuse to point the nailer at yourself or any bystanders. Serious injury may occur.

H5571 34˚ Framing Nailer Kit |