MODEL H6187 |

1⁄2" INDUSTRIAL |

IMPACT WRENCH |

INSTRUCTION SHEET |

EYE/EAR INJURY HAZARD! Wear safety glasses and hearing protection during use of this tool!

INJURY HAZARD!

Always disconnect tool from

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() air to prevent unexpected

air to prevent unexpected ![]()

![]() operation during service!

operation during service!

DO NOT EXCEED 150 PSI! Personal injury could occur.

SHATTERING HAZARD! Use sockets rated for impact wrench use only.

Introduction

•Operates at 90 PSI

•3.8 CFM air consumption

•95 dB sound level

•1/4” NPT air inlet

•8000 RPM free speed

•460 ft/lbs maximum torque

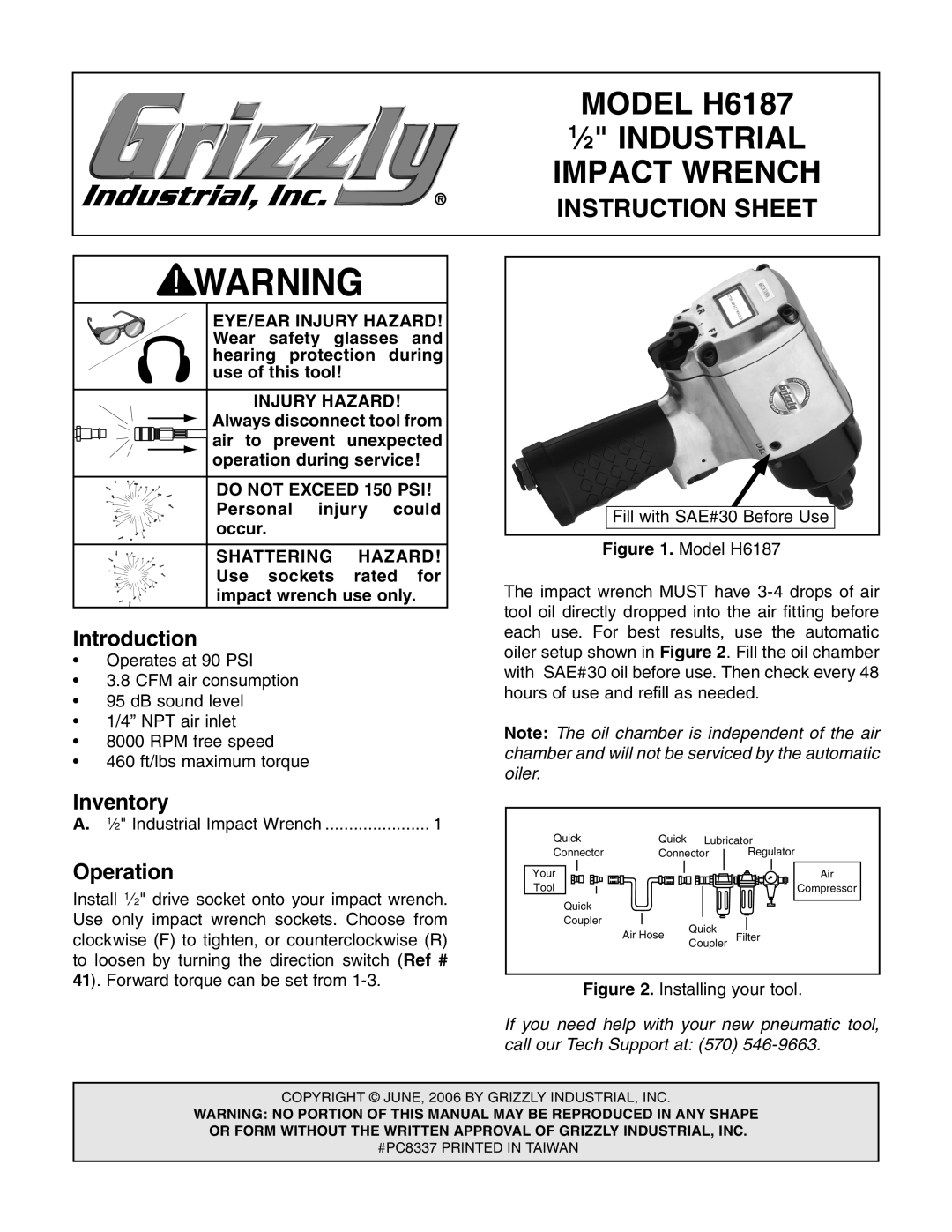

Fill with SAE#30 Before Use

Figure 1. Model H6187

The impact wrench MUST have 3-4 drops of air tool oil directly dropped into the air fitting before each use. For best results, use the automatic oiler setup shown in Figure 2. Fill the oil chamber with SAE#30 oil before use. Then check every 48 hours of use and refill as needed.

Note: The oil chamber is independent of the air chamber and will not be serviced by the automatic oiler.

Inventory |

|

A. 1⁄2" Industrial Impact Wrench | 1 |

Operation

Install 1⁄2" drive socket onto your impact wrench. Use only impact wrench sockets. Choose from clockwise (F) to tighten, or counterclockwise (R) to loosen by turning the direction switch (Ref # 41). Forward torque can be set from

Quick | Quick | Lubricator | |

Connector | Connector | Regulator | |

Your |

|

| Air |

Tool |

|

| Compressor |

Quick |

|

|

|

Coupler |

| Quick |

|

| Air Hose | Filter | |

| Coupler | ||

|

| ||

Figure 2. Installing your tool.

If you need help with your new pneumatic tool, call our Tech Support at: (570)

COPYRIGHT © JUNE, 2006 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#PC8337 PRINTED IN TAIWAN