ASSEMBLY ADJUSTMENTS

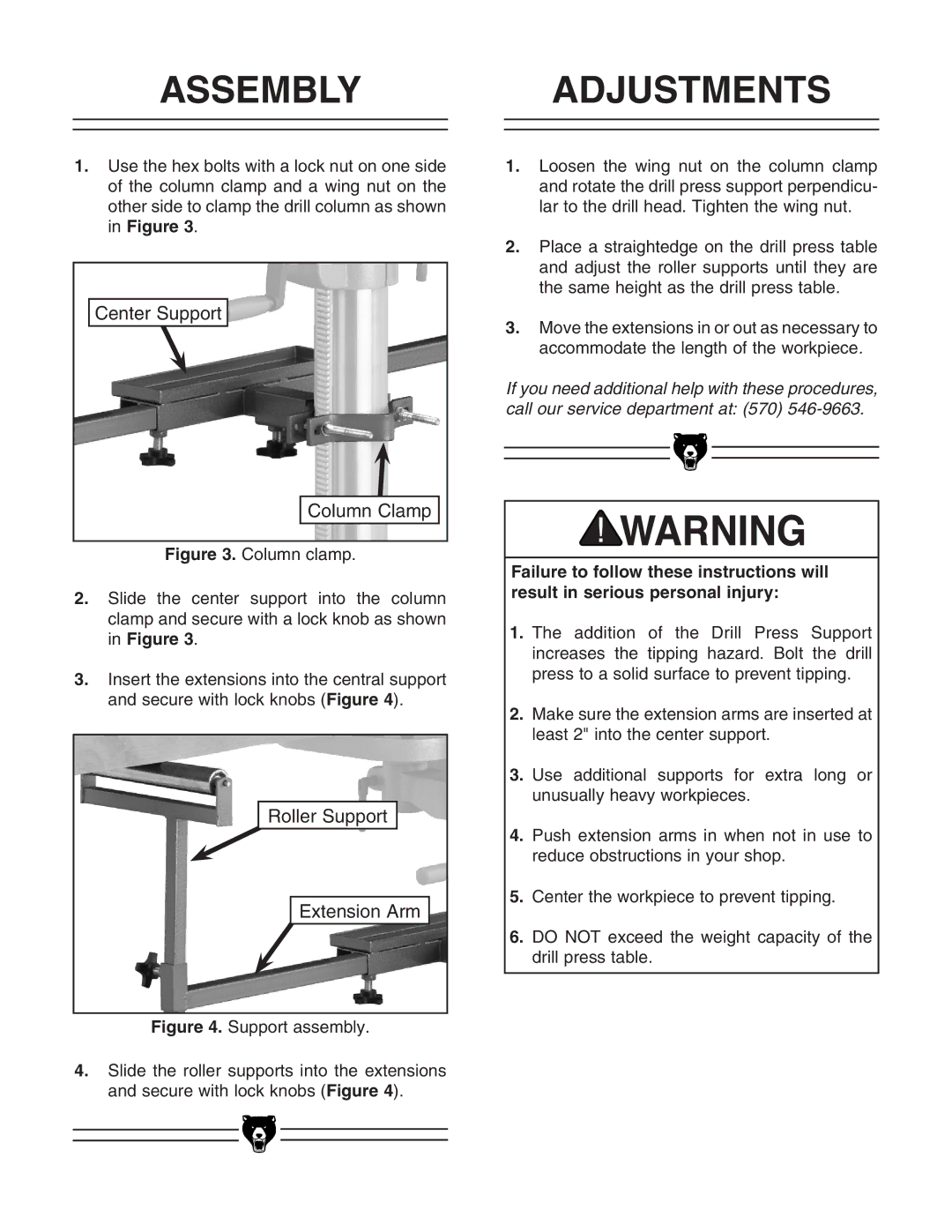

1.Use the hex bolts with a lock nut on one side of the column clamp and a wing nut on the other side to clamp the drill column as shown in Figure 3.

Center Support

Column Clamp

Figure 3. Column clamp.

2.Slide the center support into the column clamp and secure with a lock knob as shown in Figure 3.

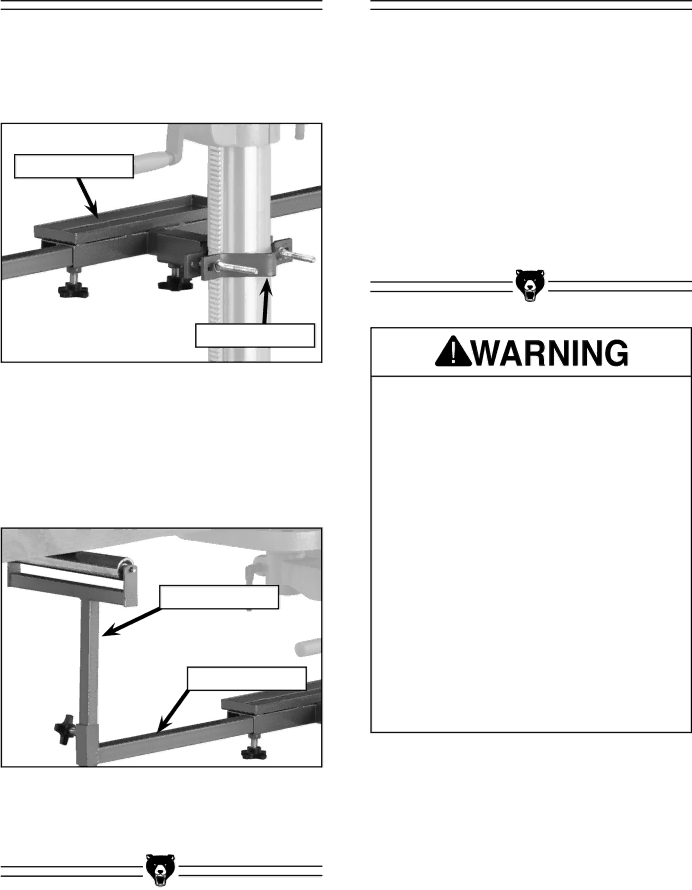

3.Insert the extensions into the central support and secure with lock knobs (Figure 4).

Roller Support

Extension Arm

Figure 4. Support assembly.

4.Slide the roller supports into the extensions and secure with lock knobs (Figure 4).

1.Loosen the wing nut on the column clamp and rotate the drill press support perpendicu- lar to the drill head. Tighten the wing nut.

2.Place a straightedge on the drill press table and adjust the roller supports until they are the same height as the drill press table.

3.Move the extensions in or out as necessary to accommodate the length of the workpiece.

If you need additional help with these procedures, call our service department at: (570)

Failure to follow these instructions will result in serious personal injury:

1.The addition of the Drill Press Support increases the tipping hazard. Bolt the drill press to a solid surface to prevent tipping.

2.Make sure the extension arms are inserted at least 2" into the center support.

3.Use additional supports for extra long or unusually heavy workpieces.

4.Push extension arms in when not in use to reduce obstructions in your shop.

5.Center the workpiece to prevent tipping.

6.DO NOT exceed the weight capacity of the drill press table.