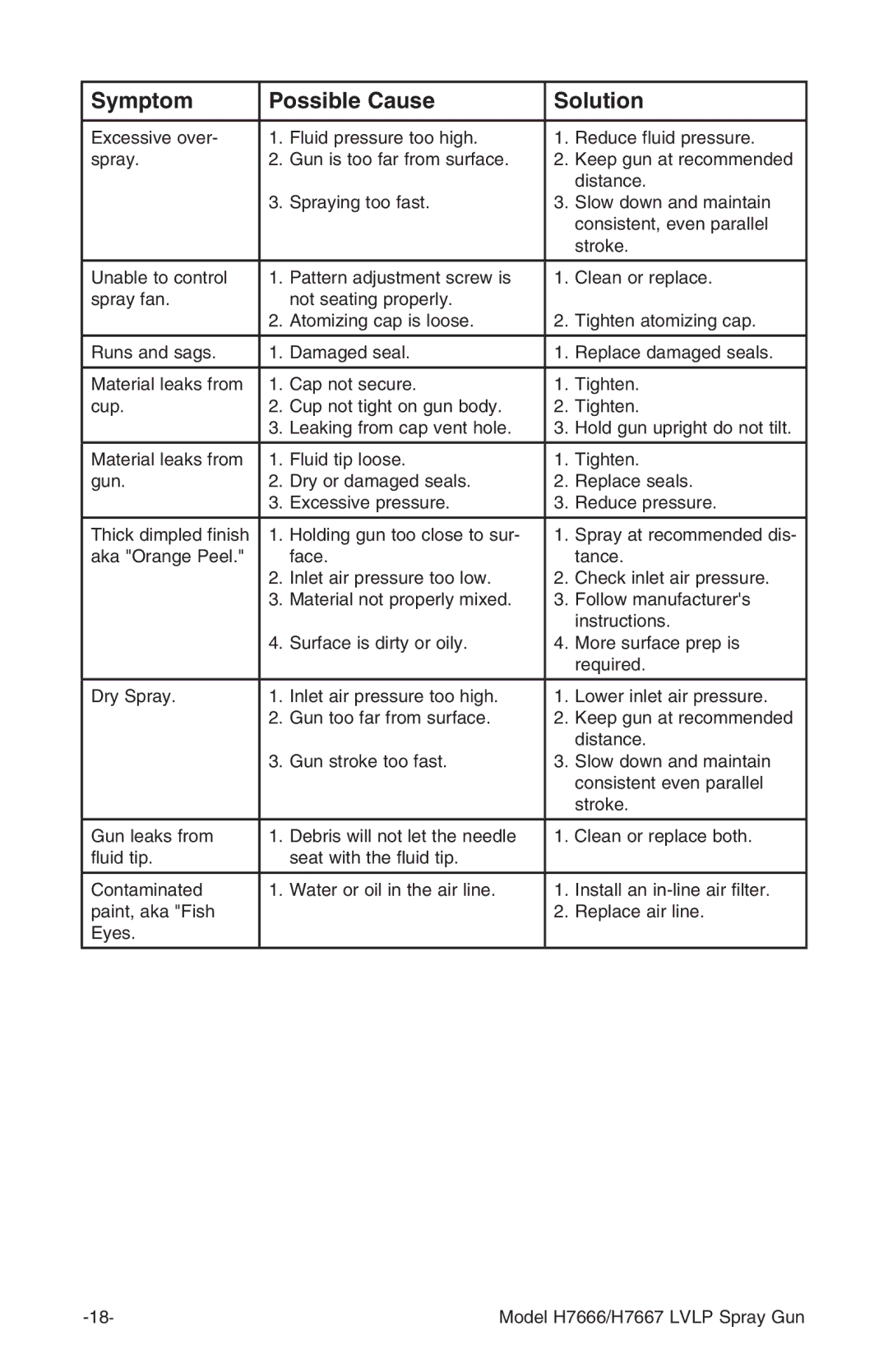

Symptom | Possible Cause | Solution | ||

|

|

|

|

|

Excessive over- | 1. | Fluid pressure too high. | 1. | Reduce fluid pressure. |

spray. | 2. | Gun is too far from surface. | 2. | Keep gun at recommended |

|

|

|

| distance. |

| 3. | Spraying too fast. | 3. | Slow down and maintain |

|

|

|

| consistent, even parallel |

|

|

|

| stroke. |

|

|

|

|

|

Unable to control | 1. | Pattern adjustment screw is | 1. | Clean or replace. |

spray fan. |

| not seating properly. |

|

|

| 2. | Atomizing cap is loose. | 2. | Tighten atomizing cap. |

|

|

|

|

|

Runs and sags. | 1. | Damaged seal. | 1. | Replace damaged seals. |

|

|

|

|

|

Material leaks from | 1. | Cap not secure. | 1. | Tighten. |

cup. | 2. | Cup not tight on gun body. | 2. | Tighten. |

| 3. | Leaking from cap vent hole. | 3. | Hold gun upright do not tilt. |

|

|

|

|

|

Material leaks from | 1. | Fluid tip loose. | 1. | Tighten. |

gun. | 2. | Dry or damaged seals. | 2. | Replace seals. |

| 3. | Excessive pressure. | 3. | Reduce pressure. |

|

|

|

|

|

Thick dimpled finish | 1. | Holding gun too close to sur- | 1. | Spray at recommended dis- |

aka "Orange Peel." |

| face. |

| tance. |

| 2. | Inlet air pressure too low. | 2. | Check inlet air pressure. |

| 3. | Material not properly mixed. | 3. | Follow manufacturer's |

|

|

|

| instructions. |

| 4. | Surface is dirty or oily. | 4. | More surface prep is |

|

|

|

| required. |

|

|

|

|

|

Dry Spray. | 1. | Inlet air pressure too high. | 1. | Lower inlet air pressure. |

| 2. | Gun too far from surface. | 2. | Keep gun at recommended |

|

|

|

| distance. |

| 3. | Gun stroke too fast. | 3. | Slow down and maintain |

|

|

|

| consistent even parallel |

|

|

|

| stroke. |

|

|

|

| |

Gun leaks from | 1. | Debris will not let the needle | 1. Clean or replace both. | |

fluid tip. |

| seat with the fluid tip. |

|

|

|

|

|

|

|

Contaminated | 1. | Water or oil in the air line. | 1. | Install an |

paint, aka "Fish |

|

| 2. | Replace air line. |

Eyes. |

|

|

|

|

|

|

|

|

|

Model H7666/H7667 LVLP Spray Gun |