ALWAYS visually inspect and perform | a |

“ring test” on a wheel before assembly. DO | |

NOT use damaged wheels! |

|

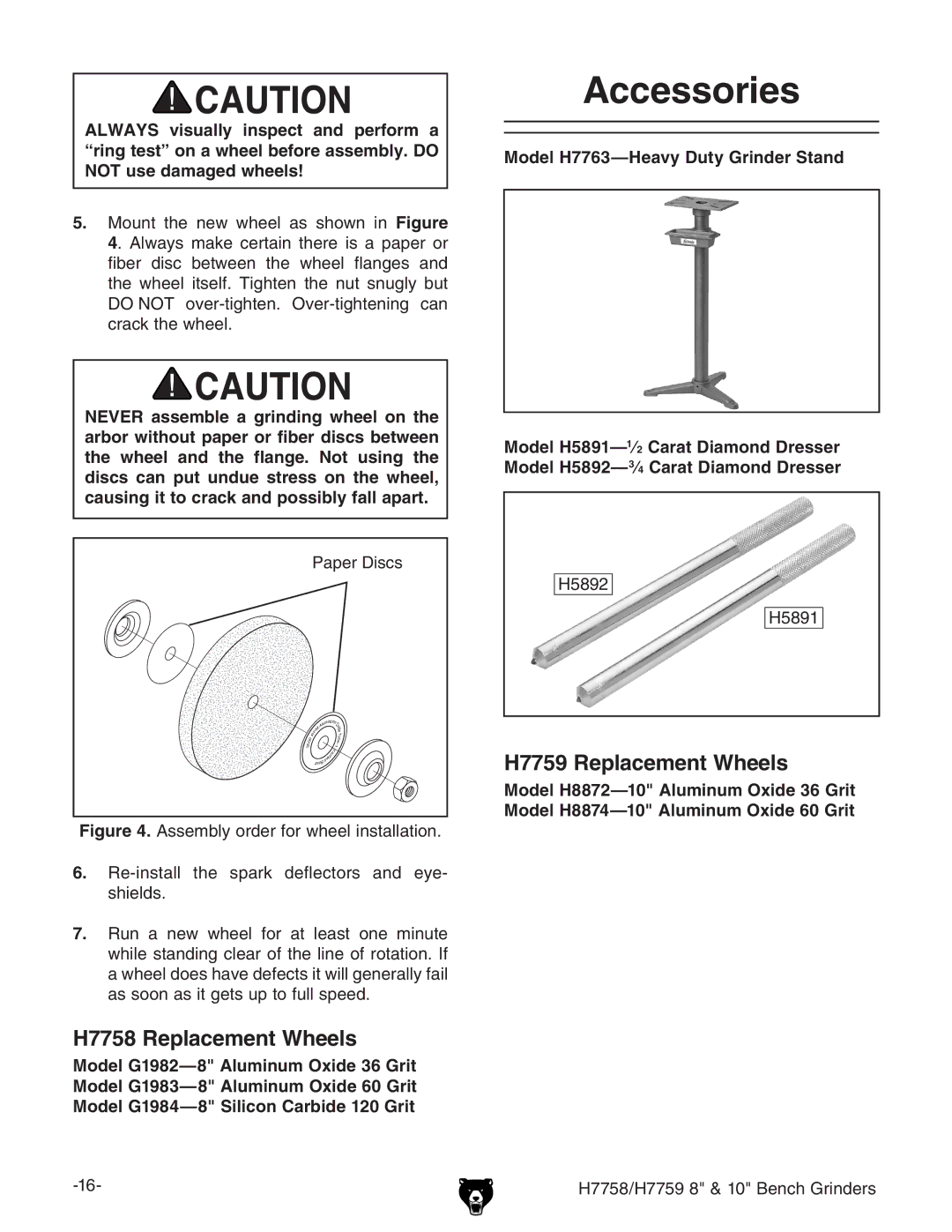

5.Mount the new wheel as shown in Figure 4. Always make certain there is a paper or fiber disc between the wheel flanges and the wheel itself. Tighten the nut snugly but DO NOT

NEVER assemble a grinding wheel on the arbor without paper or fiber discs between the wheel and the flange. Not using the discs can put undue stress on the wheel, causing it to crack and possibly fall apart.

�����������

|

|

|

|

|

| � | ����� |

|

| |

|

|

|

|

| �� |

|

|

| � | |

|

|

|

| � |

|

|

| � | ||

|

|

|

| � |

|

|

|

| ||

|

|

| � | � |

|

|

|

|

| � |

|

|

|

|

|

|

|

|

| � | |

|

| � � |

|

|

|

|

|

|

| � |

| � |

|

|

|

|

|

|

| � | |

� |

|

|

|

|

|

|

|

| � | |

|

|

|

|

|

|

|

|

| � | |

� |

|

|

|

|

|

|

|

| � | � |

� |

|

|

|

|

|

|

| � |

| |

|

|

|

|

|

|

| � |

|

| |

|

|

|

|

|

|

| �� |

|

|

|

|

|

|

|

|

|

| �� |

|

|

|

|

|

|

|

|

| �� |

|

|

| |

|

|

| ����� | �� | � |

|

|

|

| |

|

|

|

|

|

|

|

|

| ||

Figure 4. Assembly order for wheel installation.

6.Re-install the spark deflectors and eye- shields.

7.Run a new wheel for at least one minute while standing clear of the line of rotation. If a wheel does have defects it will generally fail as soon as it gets up to full speed.

H7758 Replacement Wheels

Model

Accessories

Model

Model H5891— |

| ⁄2 Carat Diamond Dresser | |

1 |

| ⁄4 Carat Diamond Dresser | |

Model H5892— | 3 | ||

H5892

H5891

H7759 Replacement Wheels

Model

H7758/H7759 8" & 10" Bench Grinders