To re-install the bottom jaws:

1.Clean bottom jaws and jaw guides with min- eral spirits. When dry, apply a thin coat of ISO 32 or equivalent oil to the mating surfaces.

2.Make sure safety set screw is properly installed in jaw guide #4.

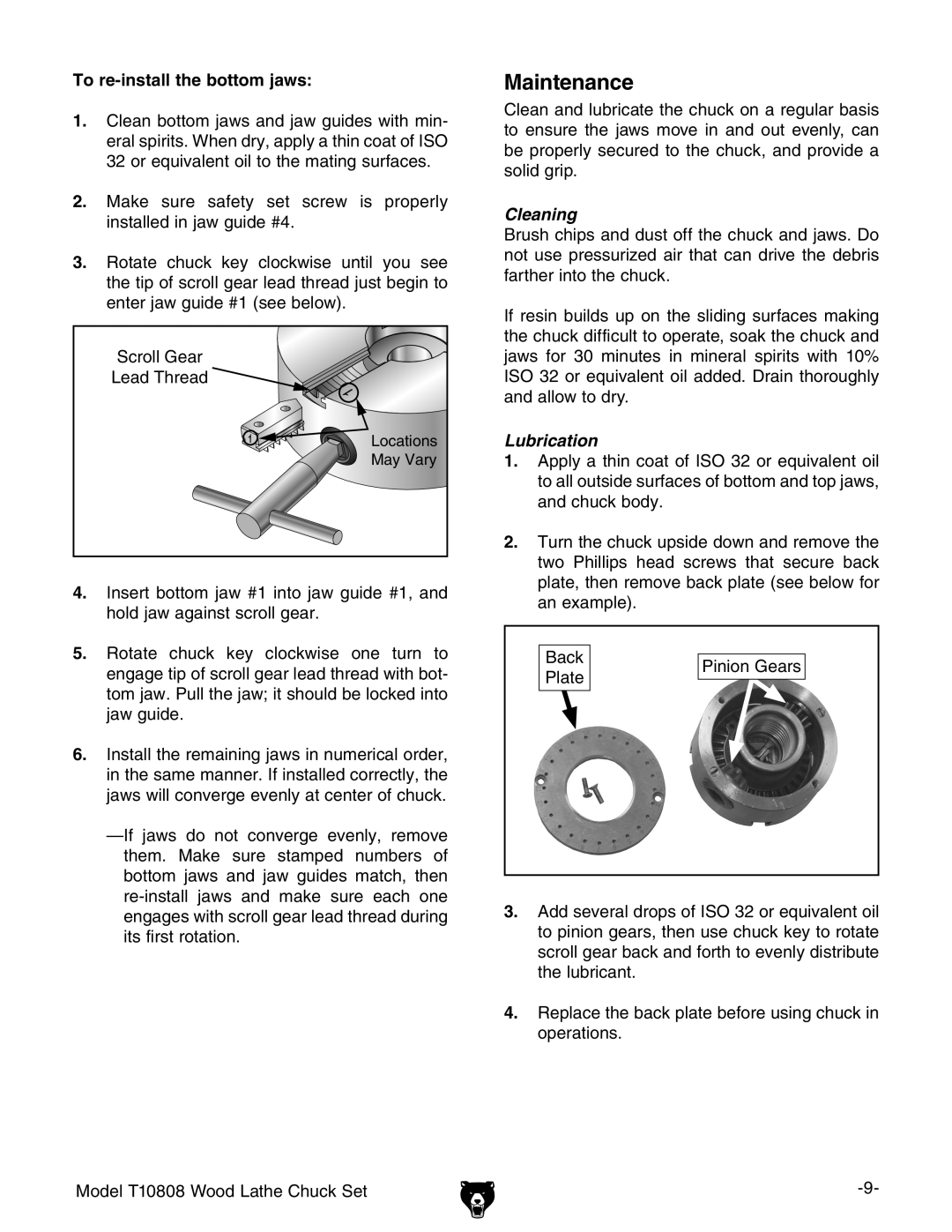

3.Rotate chuck key clockwise until you see the tip of scroll gear lead thread just begin to enter jaw guide #1 (see below).

Scroll Gear |

|

Lead Thread | 1 |

| |

1 | Locations |

| |

| May Vary |

4.Insert bottom jaw #1 into jaw guide #1, and hold jaw against scroll gear.

5.Rotate chuck key clockwise one turn to engage tip of scroll gear lead thread with bot- tom jaw. Pull the jaw; it should be locked into jaw guide.

6.Install the remaining jaws in numerical order, in the same manner. If installed correctly, the jaws will converge evenly at center of chuck.

Maintenance

Clean and lubricate the chuck on a regular basis to ensure the jaws move in and out evenly, can be properly secured to the chuck, and provide a solid grip.

Cleaning

Brush chips and dust off the chuck and jaws. Do not use pressurized air that can drive the debris farther into the chuck.

If resin builds up on the sliding surfaces making the chuck difficult to operate, soak the chuck and jaws for 30 minutes in mineral spirits with 10% ISO 32 or equivalent oil added. Drain thoroughly and allow to dry.

Lubrication

1.Apply a thin coat of ISO 32 or equivalent oil to all outside surfaces of bottom and top jaws, and chuck body.

2.Turn the chuck upside down and remove the two Phillips head screws that secure back plate, then remove back plate (see below for an example).

Back |

|

| |

Pinion Gears | |||

Plate |

| ||

|

| ||

| |||

|

|

|

3.Add several drops of ISO 32 or equivalent oil to pinion gears, then use chuck key to rotate scroll gear back and forth to evenly distribute the lubricant.

4.Replace the back plate before using chuck in operations.

Model T10808 Wood Lathe Chuck Set |