Tool Storage specifications

Grizzly Tool Storage has emerged as a leading name in the woodworking and metalworking industries, offering an impressive range of storage solutions designed to meet the needs of professionals and hobbyists alike. Known for their durability, functionality, and innovative design, Grizzly Tool Storage products provide users with effective ways to organize and protect their valuable tools and equipment.One of the standout features of Grizzly Tool Storage is its robust construction. Many of their storage units are made from heavy-duty steel, ensuring they can withstand the rigors of a busy workshop or garage. This durability not only protects the tools from physical damage but also contributes to the longevity of the storage units themselves. Furthermore, Grizzly employs high-quality finishes, including powder coating, to protect against rust and corrosion, extending the life of their products.

Another key characteristic of Grizzly Tool Storage is the thoughtful organization features integrated into their designs. Ranging from toolboxes and cabinets to shelving units, the storage systems often include adjustable shelves, drawer dividers, and pegboard backs that allow users to customize the layout according to their specific needs. This adaptability ensures that tools are easily accessible and can be stored in a way that makes sense for the user’s workflow.

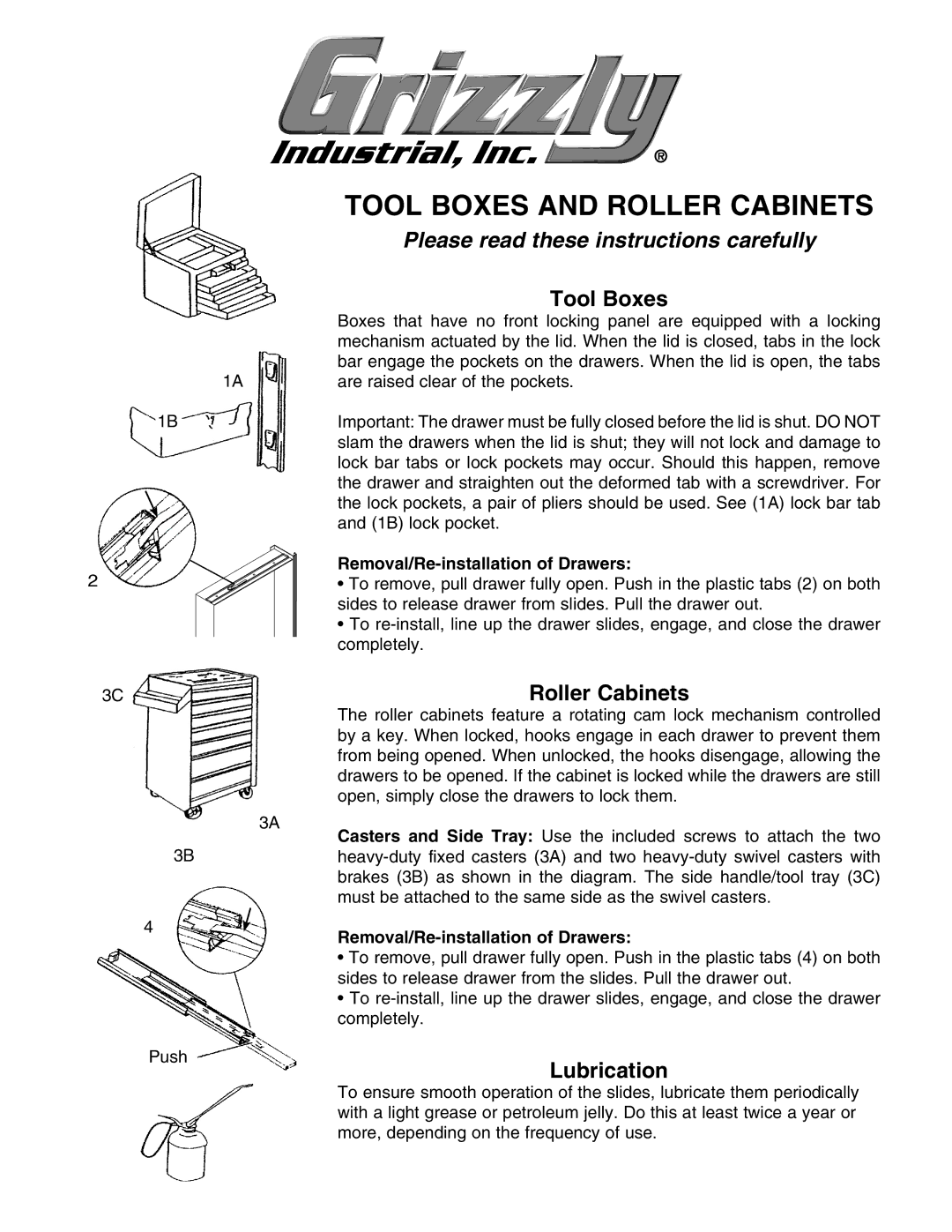

Incorporating advanced technologies is another hallmark of Grizzly Tool Storage. Many storage solutions are designed with ball-bearing slides for smooth operation in drawers, making it simple to access tools without the frustration of sticking or jamming. Additionally, some units come equipped with locking mechanisms that safeguard valuable equipment from theft or unauthorized access, providing peace of mind for users.

Efficient use of space is another advantage offered by Grizzly Tool Storage. Their modular designs allow for stacking and combining different storage units, maximizing the vertical space in a workshop or garage. This feature is particularly beneficial for smaller work areas, where every inch counts.

Overall, Grizzly Tool Storage stands out not only for its high-quality construction and smart organizational features but also for its commitment to innovation. The company's focus on user-friendly designs ensures that every woodworking or metalworking enthusiast can find the right storage solution to fit their unique requirements, enhancing productivity and efficiency in any setting. Whether for professional or personal use, Grizzly Tool Storage is synonymous with quality and practicality, setting a high standard in tool organization.