Operating the Nailer

1.Attach the Nailer to the air supply at the Air Inlet (122). Start your compressor and check the pressure making sure it is set at the recommended

2.To fire, place the nose of the Nailer on the workpiece. The Nailer should not fire if the Safety Trigger (123) is not depressed. Once depressed, gently and briefly squeeze the Trigger (125) once. Do not fire repeatedly. Nails could bounce off of one another, damaging the work piece or causing PERSONAL INJURY.

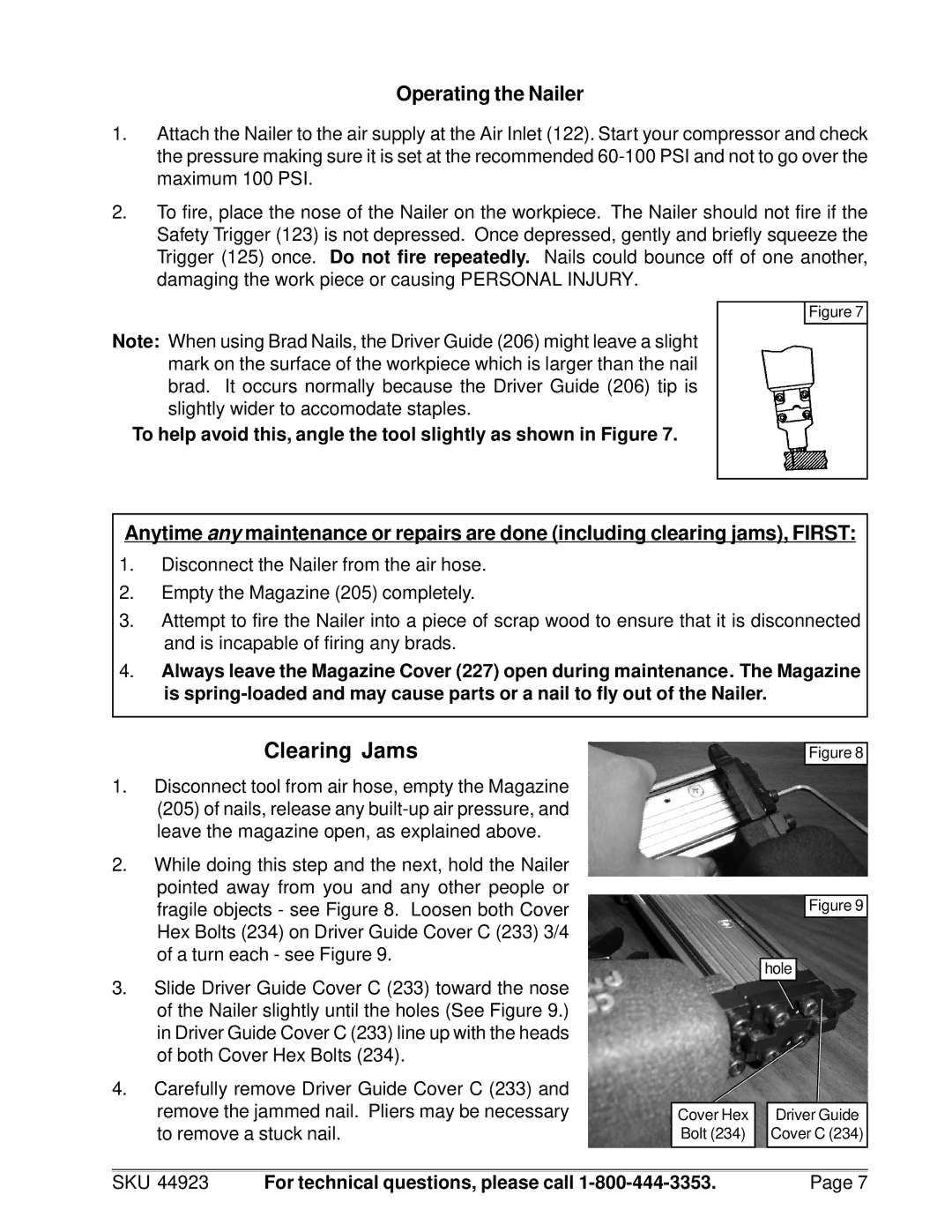

Note: When using Brad Nails, the Driver Guide (206) might leave a slight mark on the surface of the workpiece which is larger than the nail brad. It occurs normally because the Driver Guide (206) tip is slightly wider to accomodate staples.

To help avoid this, angle the tool slightly as shown in Figure 7.

Figure 7

Anytime any maintenance or repairs are done (including clearing jams), FIRST:

1.Disconnect the Nailer from the air hose.

2.Empty the Magazine (205) completely.

3.Attempt to fire the Nailer into a piece of scrap wood to ensure that it is disconnected and is incapable of firing any brads.

4.Always leave the Magazine Cover (227) open during maintenance. The Magazine is

Clearing Jams

1.Disconnect tool from air hose, empty the Magazine (205) of nails, release any

2.While doing this step and the next, hold the Nailer pointed away from you and any other people or fragile objects - see Figure 8. Loosen both Cover Hex Bolts (234) on Driver Guide Cover C (233) 3/4 of a turn each - see Figure 9.

3.Slide Driver Guide Cover C (233) toward the nose of the Nailer slightly until the holes (See Figure 9.) in Driver Guide Cover C (233) line up with the heads of both Cover Hex Bolts (234).

4.Carefully remove Driver Guide Cover C (233) and remove the jammed nail. Pliers may be necessary to remove a stuck nail.

Figure 8

Figure 9

hole

Cover Hex Driver Guide Bolt (234) Cover C (234)

SKU 44923 | For technical questions, please call | Page 7 |