NOTE:Performance of the compressor (if powered by line voltage) may vary depending on variations in local line voltage. Extension cord usage may also affect tool performance.

WARNING: The warnings, cautions, and instructions discussed in this instruction manual cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be built into this product, but must be supplied by the operator.

WARNING: The brass components of this product contain lead, a chemical known to the State of California to cause birth defects (or other reproductive harm). (California Health & Safety code 25249.5, et seq.)

Unpacking

When unpacking, check to make sure the parts listed on page 6 are included. If any parts are missing or broken, please call Harbor Freight Tools at the number on the cover of this manual as soon as possible.

Operation

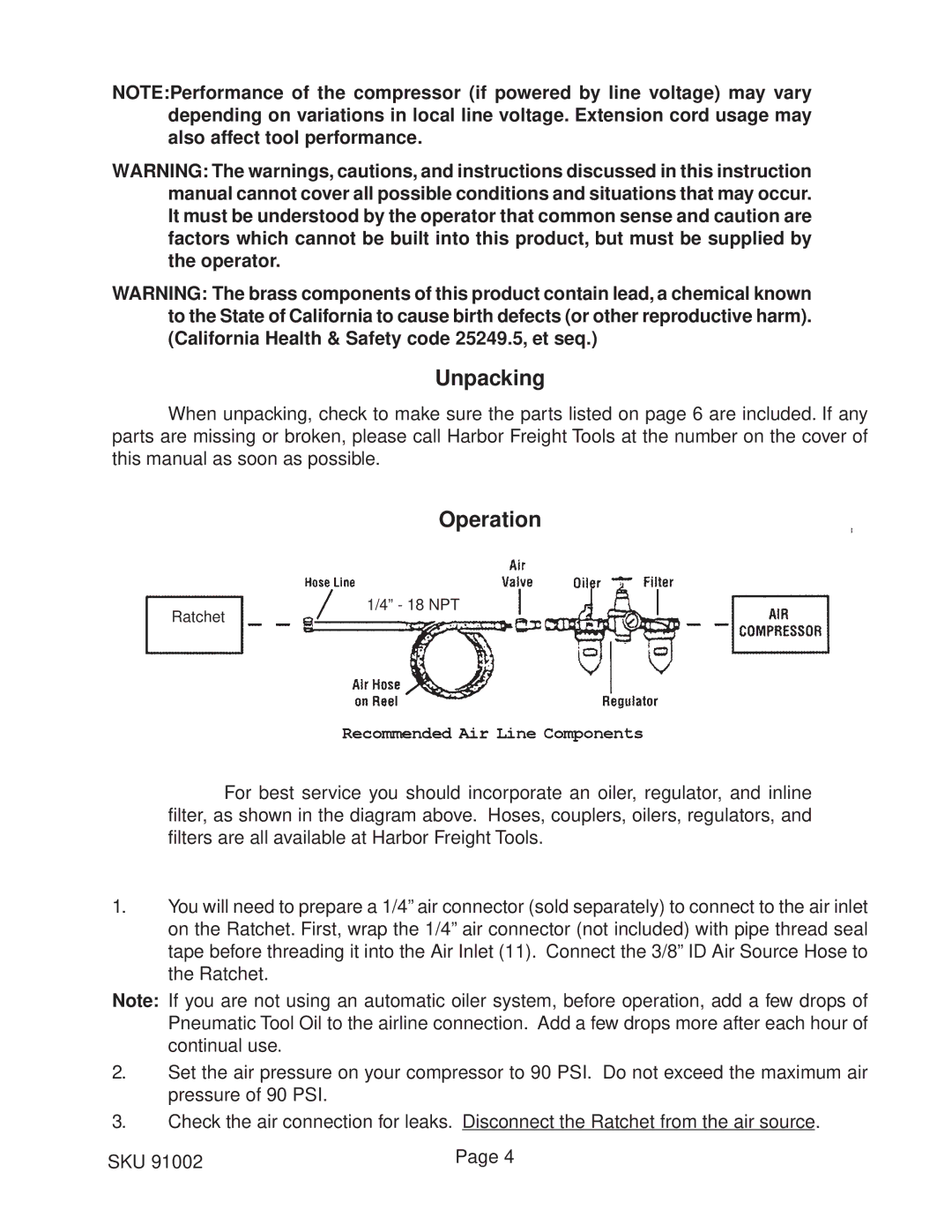

1/4” - 18 NPT

Ratchet

For best service you should incorporate an oiler, regulator, and inline filter, as shown in the diagram above. Hoses, couplers, oilers, regulators, and filters are all available at Harbor Freight Tools.

1.You will need to prepare a 1/4” air connector (sold separately) to connect to the air inlet on the Ratchet. First, wrap the 1/4” air connector (not included) with pipe thread seal tape before threading it into the Air Inlet (11). Connect the 3/8” ID Air Source Hose to the Ratchet.

Note: If you are not using an automatic oiler system, before operation, add a few drops of Pneumatic Tool Oil to the airline connection. Add a few drops more after each hour of continual use.

2.Set the air pressure on your compressor to 90 PSI. Do not exceed the maximum air pressure of 90 PSI.

3.Check the air connection for leaks. Disconnect the Ratchet from the air source.

SKU 91002 | Page 4 |