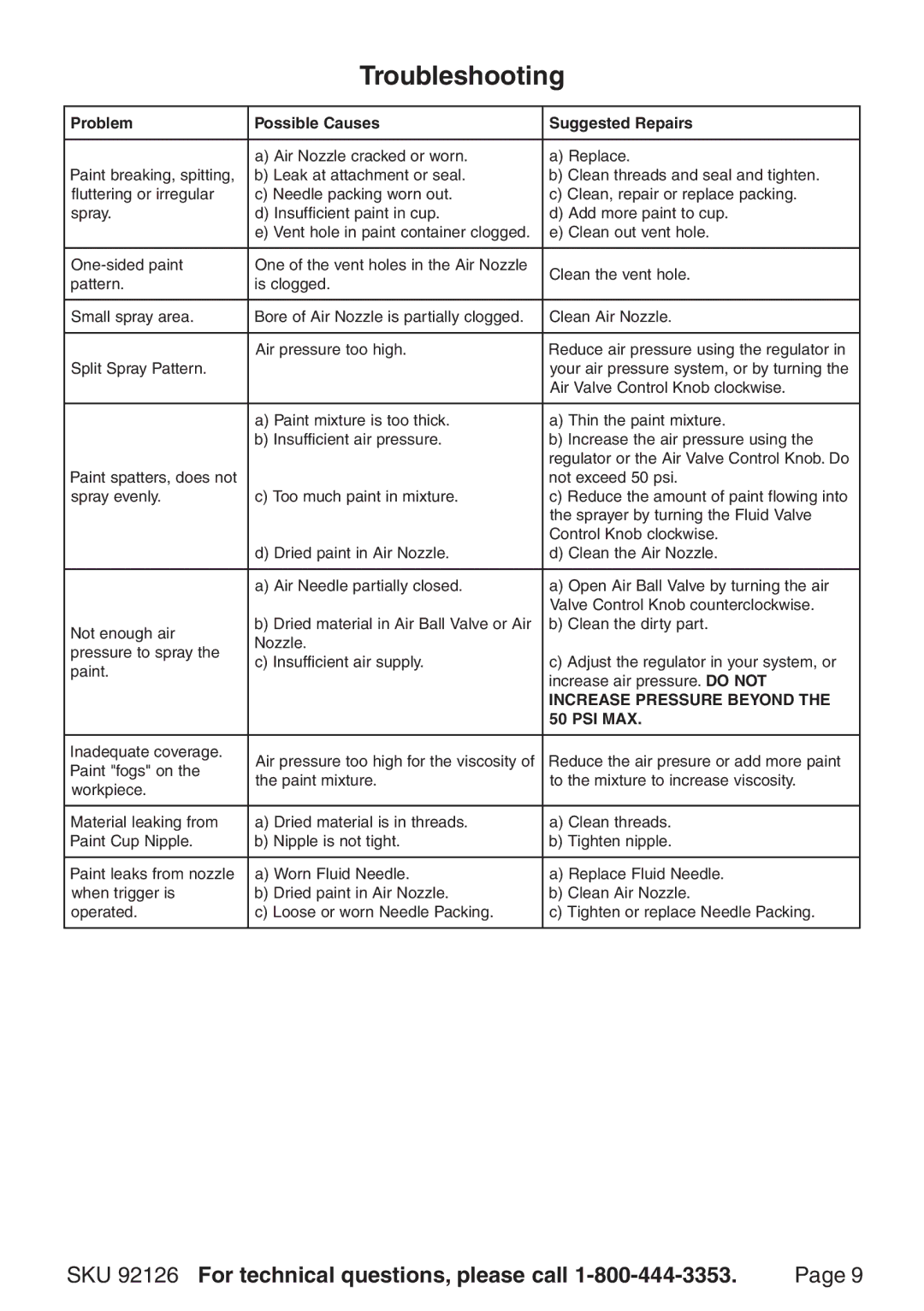

Troubleshooting

Problem | Possible Causes | Suggested Repairs | |

|

|

| |

| a) Air Nozzle cracked or worn. | a) Replace. | |

Paint breaking, spitting, | b) Leak at attachment or seal. | b) Clean threads and seal and tighten. | |

fluttering or irregular | c) Needle packing worn out. | c) Clean, repair or replace packing. | |

spray. | d) Insufficient paint in cup. | d) Add more paint to cup. | |

| e) Vent hole in paint container clogged. | e) Clean out vent hole. | |

|

|

| |

One of the vent holes in the Air Nozzle | Clean the vent hole. | ||

pattern. | is clogged. | ||

| |||

|

|

| |

Small spray area. | Bore of Air Nozzle is partially clogged. | Clean Air Nozzle. | |

|

|

| |

| Air pressure too high. | Reduce air pressure using the regulator in | |

Split Spray Pattern. |

| your air pressure system, or by turning the | |

|

| Air Valve Control Knob clockwise. | |

|

|

| |

| a) Paint mixture is too thick. | a) Thin the paint mixture. | |

| b) Insufficient air pressure. | b) Increase the air pressure using the | |

|

| regulator or the Air Valve Control Knob. Do | |

Paint spatters, does not |

| not exceed 50 psi. | |

spray evenly. | c) Too much paint in mixture. | c) Reduce the amount of paint flowing into | |

|

| the sprayer by turning the Fluid Valve | |

|

| Control Knob clockwise. | |

| d) Dried paint in Air Nozzle. | d) Clean the Air Nozzle. | |

|

|

| |

| a) Air Needle partially closed. | a) Open Air Ball Valve by turning the air | |

|

| Valve Control Knob counterclockwise. | |

Not enough air | b) Dried material in Air Ball Valve or Air | b) Clean the dirty part. | |

Nozzle. |

| ||

pressure to spray the |

| ||

c) Insufficient air supply. | c) Adjust the regulator in your system, or | ||

paint. | |||

| increase air pressure. DO NOT | ||

|

| ||

|

| INCREASE PRESSURE BEYOND THE | |

|

| 50 PSI MAX. | |

|

|

| |

Inadequate coverage. | Air pressure too high for the viscosity of | Reduce the air presure or add more paint | |

Paint "fogs" on the | |||

the paint mixture. | to the mixture to increase viscosity. | ||

workpiece. | |||

|

| ||

|

|

| |

Material leaking from | a) Dried material is in threads. | a) Clean threads. | |

Paint Cup Nipple. | b) Nipple is not tight. | b) Tighten nipple. | |

|

|

| |

Paint leaks from nozzle | a) Worn Fluid Needle. | a) Replace Fluid Needle. | |

when trigger is | b) Dried paint in Air Nozzle. | b) Clean Air Nozzle. | |

operated. | c) Loose or worn Needle Packing. | c) Tighten or replace Needle Packing. | |

|

|

|

SKU 92126 For technical questions, please call | Page 9 |