Operation (continued)

Loosening

Note: Set the Forward/Reverse Valve (34) so that the anvil turns counterclockwise (reverse).

9.Place the socket (not included) over the nut you wish to loosen.

10.Grip the Impact Wrench firmly with two hands and gently squeeze the Trigger (21).

Note: If the Impact Wrench cannot loosen the nut, do not raise the air pressure on the compressor over 120 PSI. Do not attempt to loosen the nut with the Impact Wrench. Use other appropriate methods and tools to loosen the nut.

11.When the nut is loosened, release the Trigger (21). Turn off the air compressor and disconnect the hose.

12.If needed, remove the nut from the socket.

Maintenance

1.Make sure your Impact Wrench is disconnected from the air hose before attempting any maintenance.

2.Wipe the Impact Wrench down with a lint free cloth after each use.

3.Make sure the Anvil (43) is clear of dirt or debris. If possible, spray it with compressed air before each use.

4.If you do not use an inline oiler/filter system, lubricate the tool daily by holding it so that the Air Inlet (23) is facing up. Squeeze the Trigger (21), and place one or two drops of oil into the Air Inlet (23). Squeezing the Trigger (21) allows the oil to circulate in the motor.

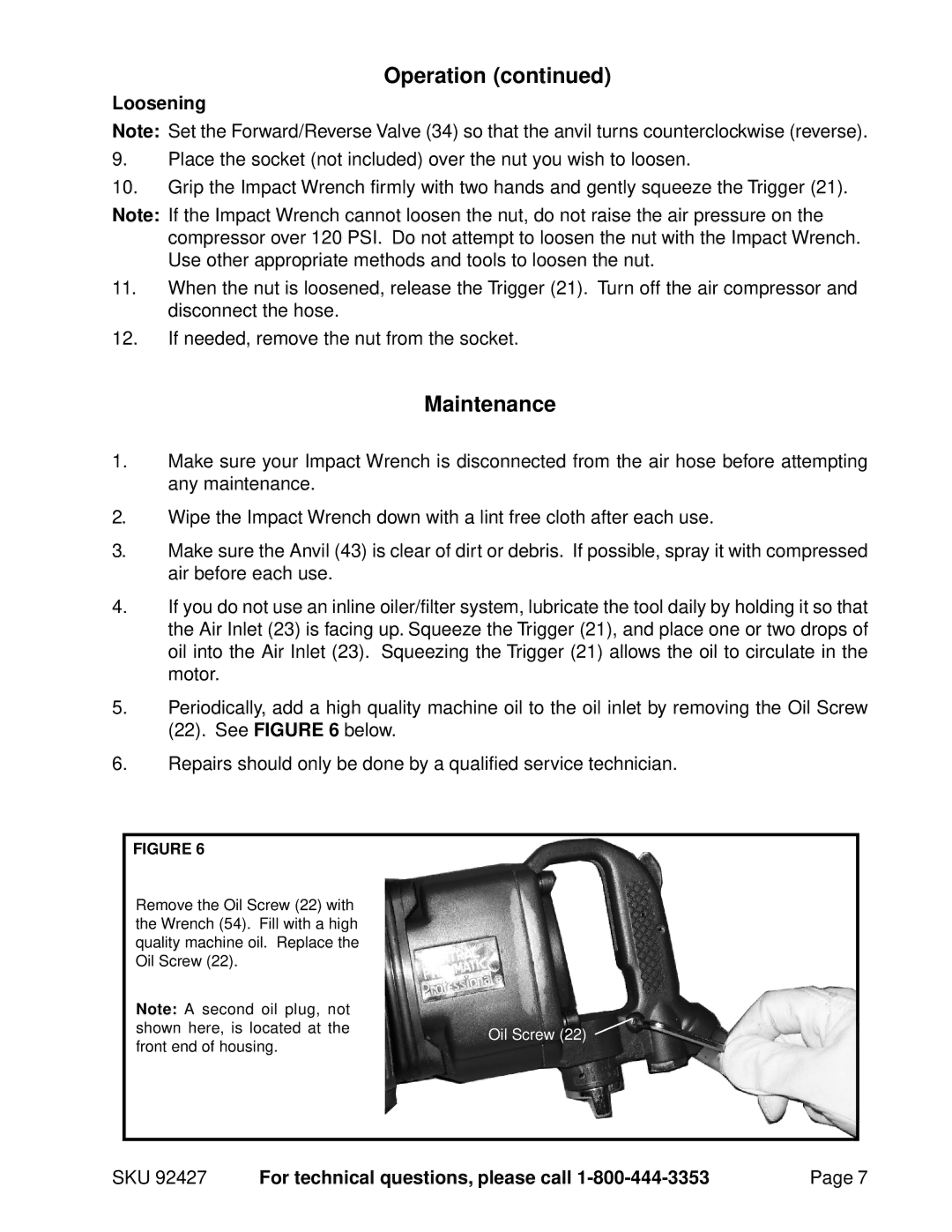

5.Periodically, add a high quality machine oil to the oil inlet by removing the Oil Screw (22). See FIGURE 6 below.

6.Repairs should only be done by a qualified service technician.

FIGURE 6

Remove the Oil Screw (22) with the Wrench (54). Fill with a high quality machine oil. Replace the Oil Screw (22).

Note: A second oil plug, not

shown here, is located at theOil Screw (22) front end of housing.

SKU 92427 | For technical questions, please call | Page 7 |