Changing the Grinding Wheel

Eventually, the Grinding Wheel may require replacement. The Grinding Wheel should be replaced when it has lost approx. 25% of its diameter. Suitable Grinding Wheels are available from Harbor Freight Tools.

1)Ensure that the replacement Grinding Wheel is no greater than 8” in Diameter nor 1.65” in Width. The bore must be designed to fit a 15/32” Spindle.

2)Be sure the Grinder is unplugged and turned OFF.

3)Pour the water out by tilting the grinder to the rear.

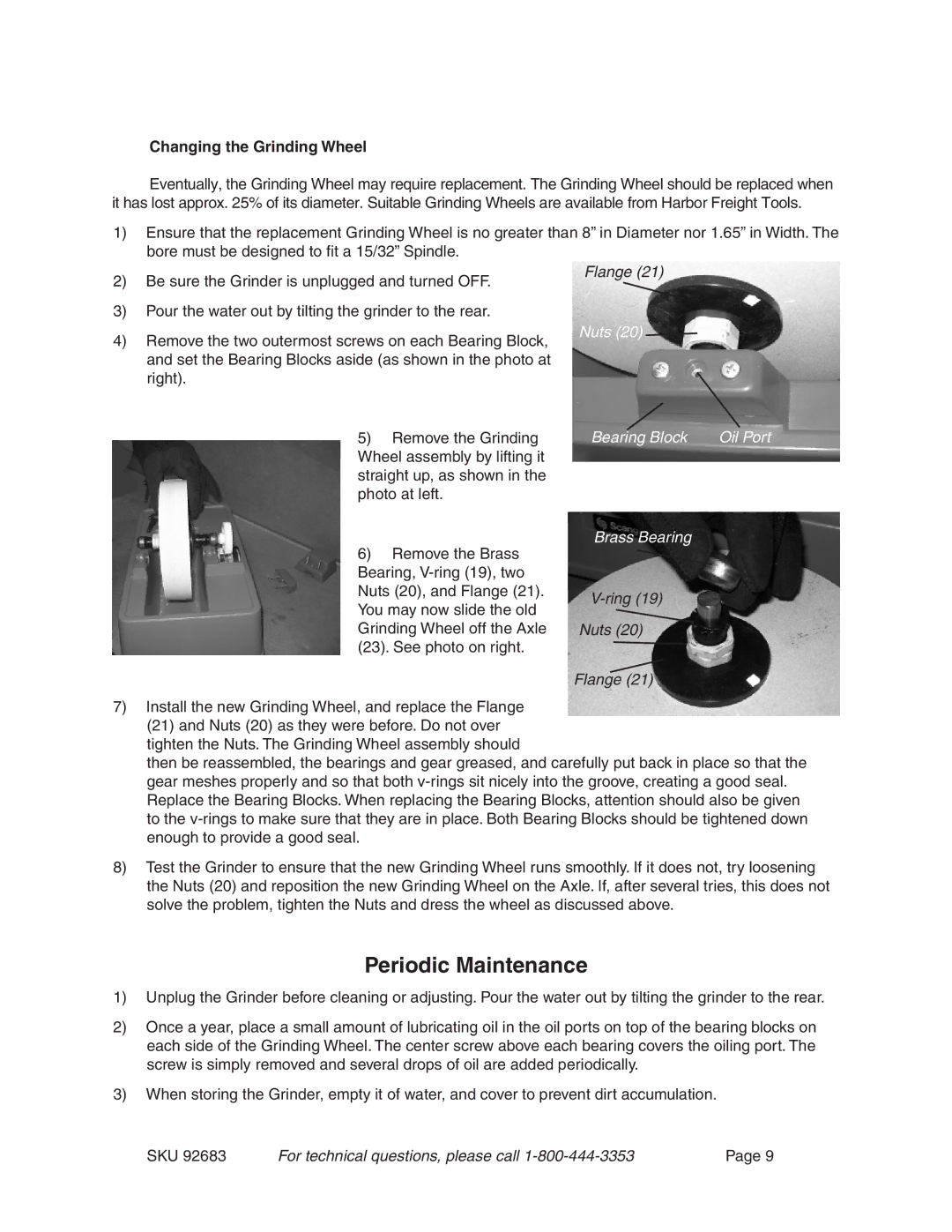

4)Remove the two outermost screws on each Bearing Block, and set the Bearing Blocks aside (as shown in the photo at right).

Flange (21)

Nuts (20)

5)Remove the Grinding Wheel assembly by lifting it straight up, as shown in the photo at left.

6)Remove the Brass Bearing,

Bearing Block | Oil Port |

Brass Bearing

V-ring (19)

Nuts (20)

Flange (21)

7)Install the new Grinding Wheel, and replace the Flange (21) and Nuts (20) as they were before. Do not over tighten the Nuts. The Grinding Wheel assembly should

then be reassembled, the bearings and gear greased, and carefully put back in place so that the gear meshes properly and so that both

8)Test the Grinder to ensure that the new Grinding Wheel runs smoothly. If it does not, try loosening the Nuts (20) and reposition the new Grinding Wheel on the Axle. If, after several tries, this does not solve the problem, tighten the Nuts and dress the wheel as discussed above.

Periodic Maintenance

1)Unplug the Grinder before cleaning or adjusting. Pour the water out by tilting the grinder to the rear.

2)Once a year, place a small amount of lubricating oil in the oil ports on top of the bearing blocks on each side of the Grinding Wheel. The center screw above each bearing covers the oiling port. The screw is simply removed and several drops of oil are added periodically.

3)When storing the Grinder, empty it of water, and cover to prevent dirt accumulation.

SKU 92683 | For technical questions, please call | Page |