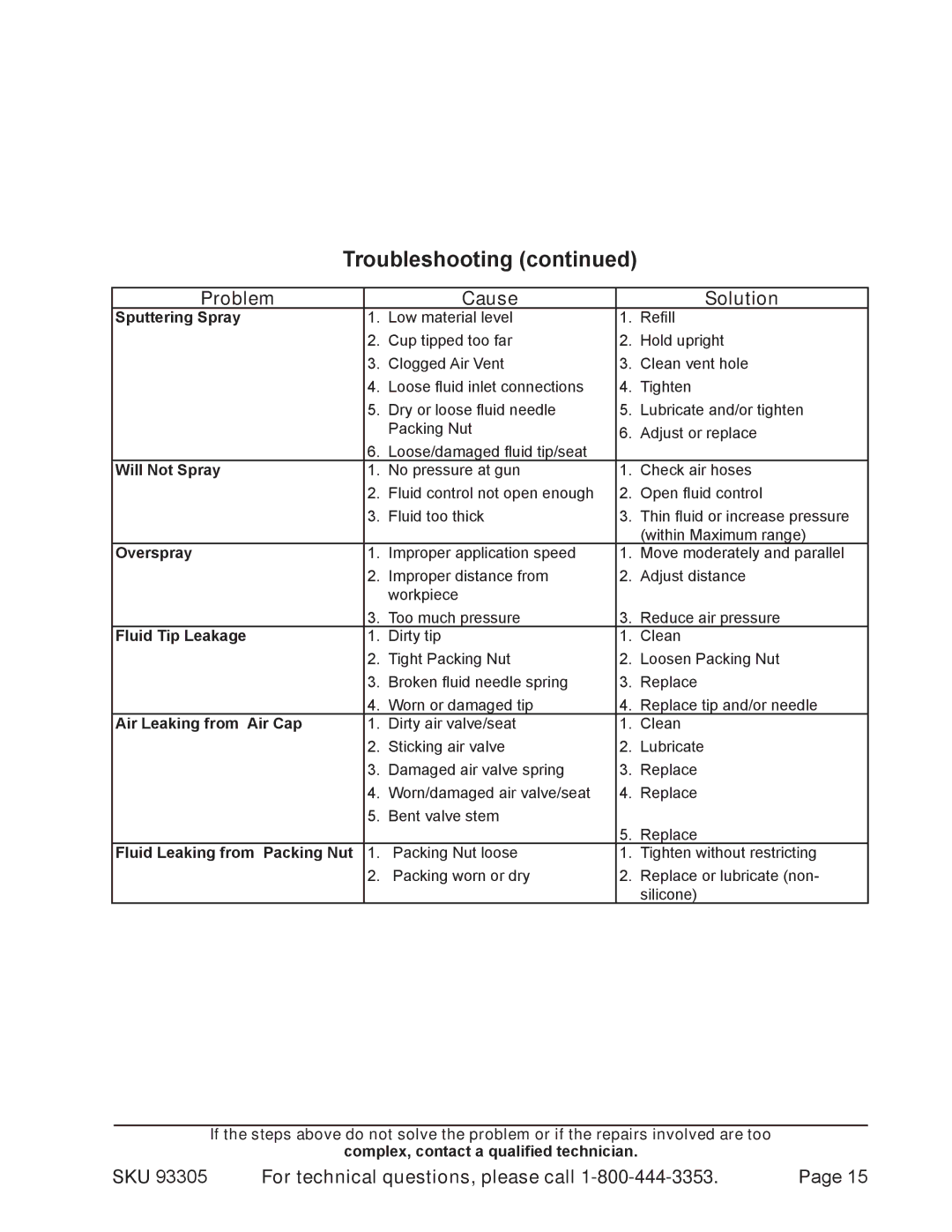

Troubleshooting (continued)

Problem |

| Cause |

| Solution |

Sputtering Spray | 1. | Low material level | 1. | Refill |

| 2. | Cup tipped too far | 2. | Hold upright |

| 3. | Clogged Air Vent | 3. | Clean vent hole |

| 4. | Loose fluid inlet connections | 4. | Tighten |

| 5. | Dry or loose fluid needle | 5. | Lubricate and/or tighten |

|

| Packing Nut | 6. | Adjust or replace |

| 6. | Loose/damaged fluid tip/seat |

|

|

Will Not Spray | 1. No pressure at gun | 1. | Check air hoses | |

| 2. | Fluid control not open enough | 2. | Open fluid control |

| 3. | Fluid too thick | 3. | Thin fluid or increase pressure |

|

|

|

| (within Maximum range) |

Overspray | 1. Improper application speed | 1. | Move moderately and parallel | |

| 2. | Improper distance from | 2. | Adjust distance |

|

| workpiece |

|

|

| 3. | Too much pressure | 3. | Reduce air pressure |

Fluid Tip Leakage | 1. | Dirty tip | 1. | Clean |

| 2. | Tight Packing Nut | 2. | Loosen Packing Nut |

| 3. | Broken fluid needle spring | 3. | Replace |

| 4. | Worn or damaged tip | 4. | Replace tip and/or needle |

Air Leaking from Air Cap | 1. | Dirty air valve/seat | 1. | Clean |

| 2. | Sticking air valve | 2. | Lubricate |

| 3. | Damaged air valve spring | 3. | Replace |

| 4. | Worn/damaged air valve/seat | 4. | Replace |

| 5. | Bent valve stem | 5. | Replace |

|

|

| ||

Fluid Leaking from Packing Nut | 1. | Packing Nut loose | 1. | Tighten without restricting |

| 2. | Packing worn or dry | 2. | Replace or lubricate (non- |

|

|

|

| silicone) |

If the steps above do not solve the problem or if the repairs involved are too

complex, contact a qualified technician.

SKU 93305 | For technical questions, please call | Page 15 |