9.WARNING! Avoid accidental electrical shock. Never staple into electrical wires, especially those which may be hidden from view.

10.WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contain chemicals known (to the State of California) to cause cancer, birth defects, or other reproductive harm. Some examples of these chemicals are: Lead from

11.WARNING: The warnings, cautions, and instructions discussed in this instruction manual cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be built into this product, but must be supplied by the operator.

OPERATING INSTRUCTIONS

Note: When loading staples or when clearing jammed staples, always keep your hands off the Handle (10).

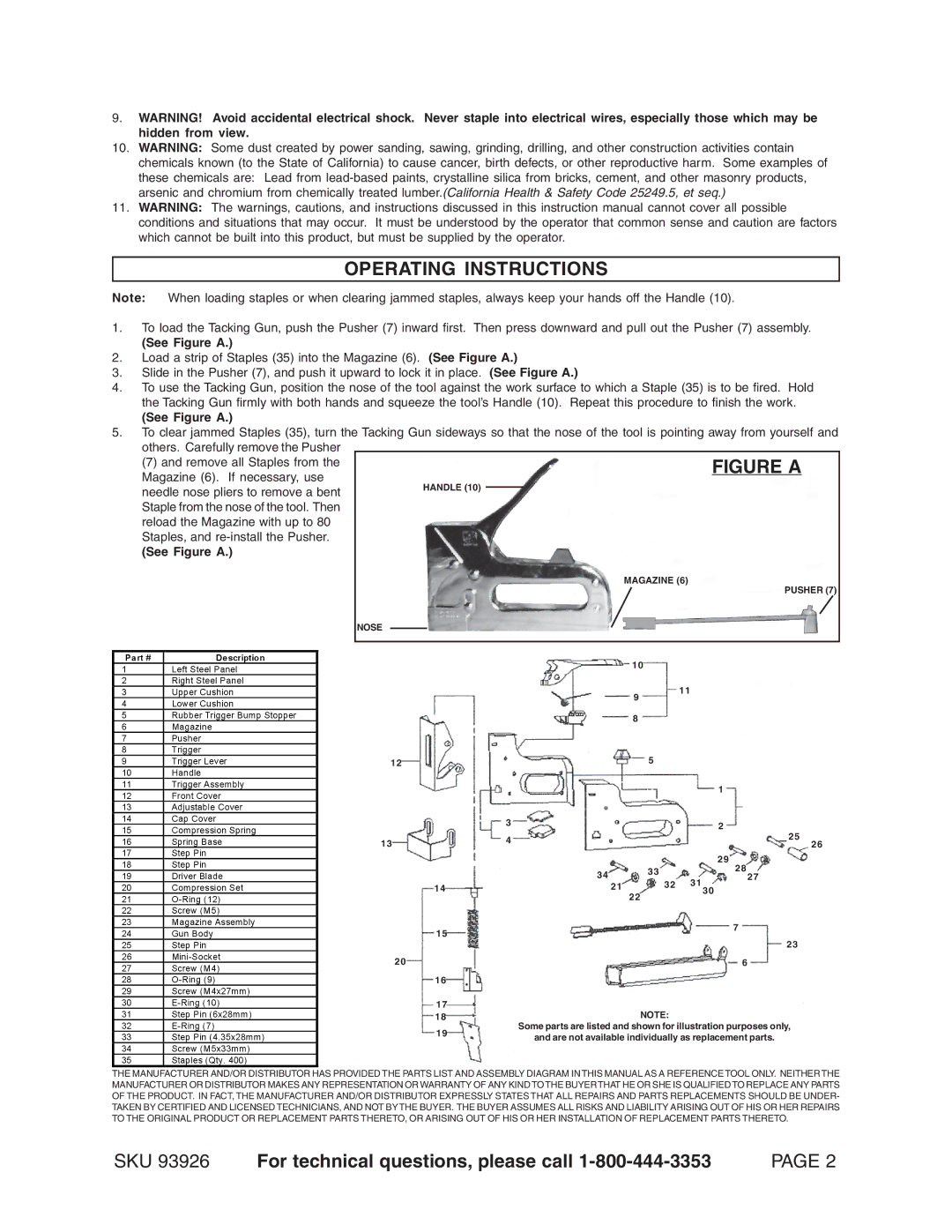

1.To load the Tacking Gun, push the Pusher (7) inward first. Then press downward and pull out the Pusher (7) assembly.

(See Figure A.)

2.Load a strip of Staples (35) into the Magazine (6). (See Figure A.)

3.Slide in the Pusher (7), and push it upward to lock it in place. (See Figure A.)

4.To use the Tacking Gun, position the nose of the tool against the work surface to which a Staple (35) is to be fired. Hold the Tacking Gun firmly with both hands and squeeze the tool’s Handle (10). Repeat this procedure to finish the work.

(See Figure A.)

5.To clear jammed Staples (35), turn the Tacking Gun sideways so that the nose of the tool is pointing away from yourself and others. Carefully remove the Pusher

(7) and remove all Staples from the Magazine (6). If necessary, use needle nose pliers to remove a bent Staple from the nose of the tool. Then reload the Magazine with up to 80 Staples, and

(See Figure A.)

MAGAZINE (6)

PUSHER (7)

NOSE

Part # | Description |

| |

1 | Left Steel Panel |

| |

2 | Right Steel Panel |

| |

3 | Upper Cushion |

| |

4 | Lower Cushion |

| |

5 | Rubber Trigger Bump Stopper |

| |

6 | Magazine |

| |

7 | Pusher |

| |

8 | Trigger |

| |

9 | Trigger Lever | 12 | |

10 | Handle |

| |

11 | Trigger Assembly |

| |

12 | Front Cover |

| |

13 | Adjustable Cover |

| |

14 | Cap Cover |

| |

15 | Compression Spring |

| |

16 | Spring Base | 13 | |

17 | Step Pin |

| |

18 | Step Pin |

| |

19 | Driver Blade |

| |

20 | Compression Set | 14 | |

21 |

| ||

22 | Screw (M5) |

| |

23 | Magazine Assembly | 15 | |

24 | Gun Body | ||

25 | Step Pin |

| |

26 | 20 | ||

27 | Screw (M4) | ||

| |||

28 | 16 | ||

29 | Screw (M4x27mm) |

| |

30 | 17 | ||

31 | Step Pin (6x28mm) | 18 | |

32 | 19 | ||

33 | Step Pin (4.35x28mm) | ||

| |||

34 | Screw (M5x33mm) |

| |

35 | Staples (Qty. 400) |

|

10

11

9

8

| 5 |

| |

|

| 1 | |

3 |

| 2 | |

|

| ||

4 |

| 25 | |

| 26 | ||

|

| ||

|

| 29 | |

34 | 33 | 28 | |

27 | |||

| |||

21 | 32 | 31 | |

| 22 | 30 | |

|

|

7

23

6

NOTE:

Some parts are listed and shown for illustration purposes only,

and are not available individually as replacement parts.

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDER- TAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISKS AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

SKU 93926 | For technical questions, please call | PAGE 2 |