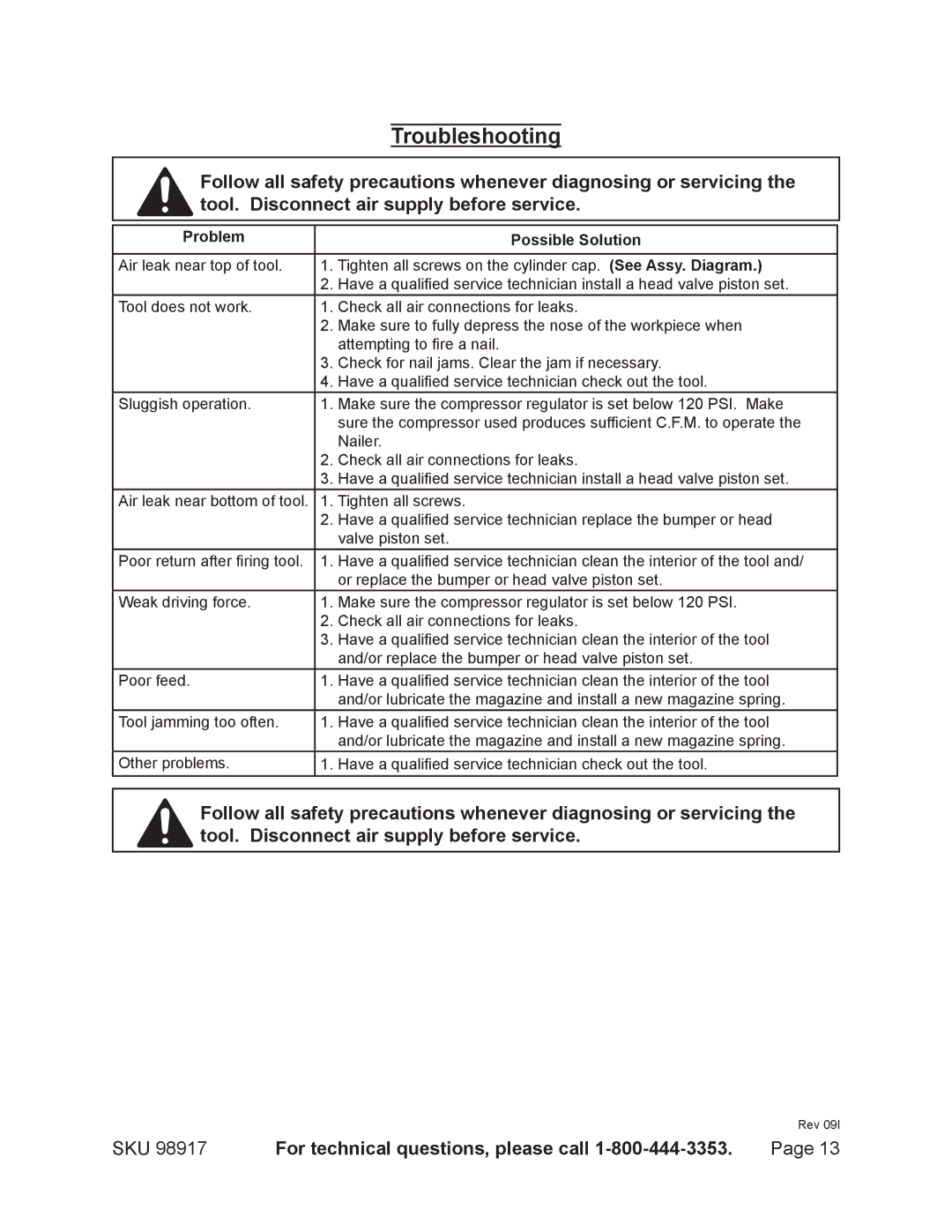

Troubleshooting

Follow all safety precautions whenever diagnosing or servicing the tool. Disconnect air supply before service.

Problem |

| Possible Solution |

|

|

|

Air leak near top of tool. | 1. | Tighten all screws on the cylinder cap. (See Assy. Diagram.) |

| 2. | Have a qualified service technician install a head valve piston set. |

Tool does not work. | 1. | Check all air connections for leaks. |

| 2. | Make sure to fully depress the nose of the workpiece when |

|

| attempting to fire a nail. |

| 3. | Check for nail jams. Clear the jam if necessary. |

| 4. | Have a qualified service technician check out the tool. |

Sluggish operation. | 1. | Make sure the compressor regulator is set below 120 PSI. Make |

|

| sure the compressor used produces sufficient C.F.M. to operate the |

|

| Nailer. |

| 2. | Check all air connections for leaks. |

| 3. | Have a qualified service technician install a head valve piston set. |

Air leak near bottom of tool. | 1. | Tighten all screws. |

| 2. | Have a qualified service technician replace the bumper or head |

|

| valve piston set. |

Poor return after firing tool. | 1. | Have a qualified service technician clean the interior of the tool and/ |

|

| or replace the bumper or head valve piston set. |

Weak driving force. | 1. | Make sure the compressor regulator is set below 120 PSI. |

| 2. | Check all air connections for leaks. |

| 3. | Have a qualified service technician clean the interior of the tool |

|

| and/or replace the bumper or head valve piston set. |

Poor feed. | 1. | Have a qualified service technician clean the interior of the tool |

|

| and/or lubricate the magazine and install a new magazine spring. |

Tool jamming too often. | 1. | Have a qualified service technician clean the interior of the tool |

|

| and/or lubricate the magazine and install a new magazine spring. |

Other problems. | 1. | Have a qualified service technician check out the tool. |

Follow all safety precautions whenever diagnosing or servicing the tool. Disconnect air supply before service.

Rev 09l

SKU 98917 | For technical questions, please call | Page 13 |