PROJECT

ITEM NO

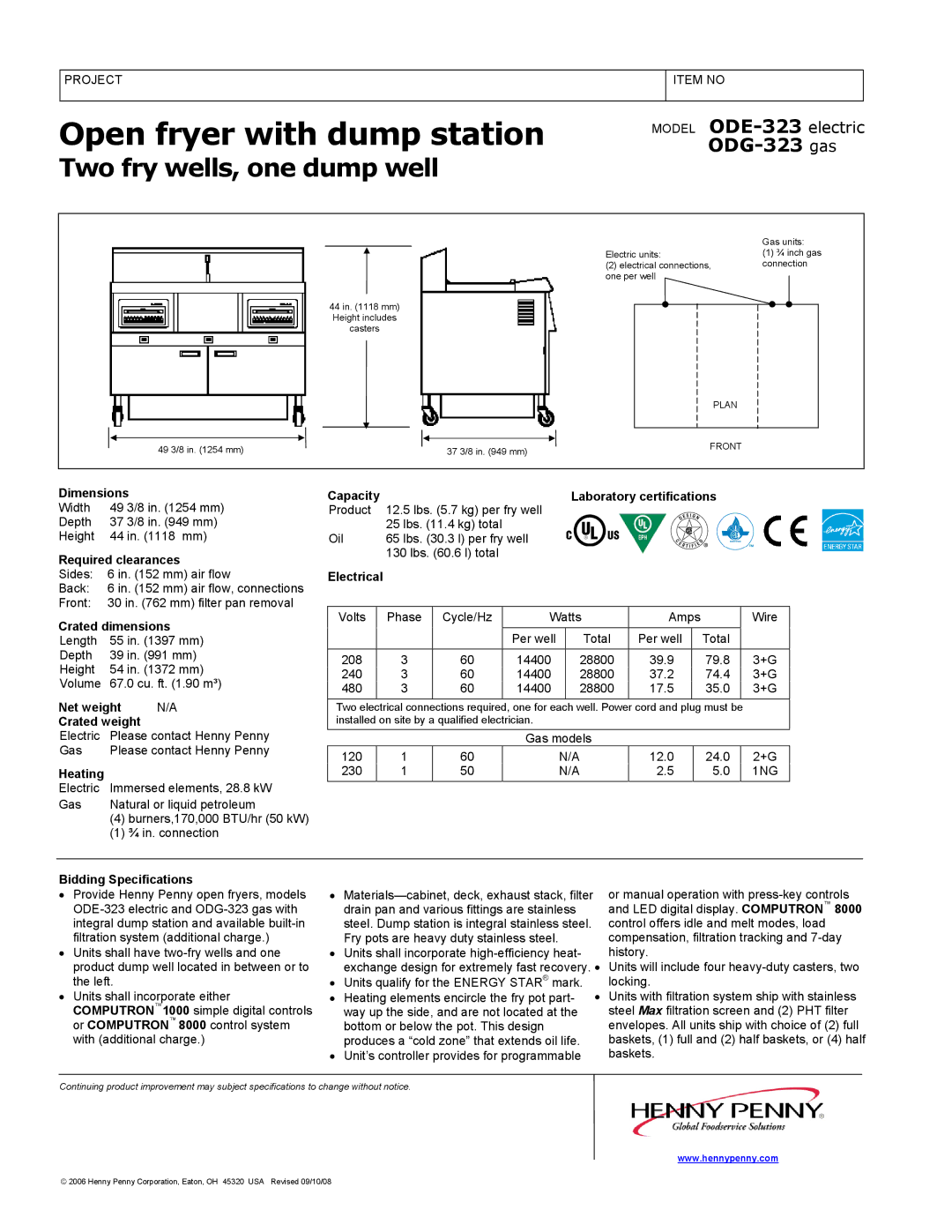

Open fryer with dump station

Two fry wells, one dump well

MODEL

| Gas units: |

Electric units: | (1) ¾ inch gas |

(2) electrical connections, | connection |

one per well |

|

44 in. (1118 mm) Height includes casters

|

|

|

| PLAN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

49 3/8 in. (1254 mm) |

| 37 3/8 in. (949 mm) | FRONT |

| |

|

|

| |||

|

|

|

|

|

|

Dimensions

Width | 49 | 3/8 in. (1254 mm) |

Depth | 37 | 3/8 in. (949 mm) |

Height | 44 in. (1118 mm) | |

Required clearances

Sides: 6 in. (152 mm) air flow

Back: 6 in. (152 mm) air flow, connections

Front: 30 in. (762 mm) filter pan removal

Crated dimensions

Length | 55 in. (1397 mm) | |

Depth | 39 in. (991 mm) | |

Height | 54 in. (1372 mm) | |

Volume | 67.0 cu. ft. (1.90 m³) | |

Net weight | N/A | |

Crated weight |

| |

Electric | Please contact Henny Penny | |

Gas | Please contact Henny Penny | |

Heating |

|

|

Electric | Immersed elements, 28.8 kW | |

Gas | Natural or liquid petroleum | |

| (4) burners,170,000 BTU/hr (50 kW) | |

| (1) ¾ in. connection | |

Capacity |

|

|

| Laboratory certifications |

| ||||

Product | 12.5 lbs. (5.7 kg) per fry well |

|

|

|

|

| |||

|

| 25 lbs. (11.4 kg) total |

|

|

|

|

|

| |

Oil | 65 lbs. (30.3 l) per fry well |

|

|

|

|

| |||

|

| 130 lbs. (60.6 l) total |

|

|

|

|

|

| |

Electrical |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

Volts |

| Phase | Cycle/Hz | Watts | Amps |

| Wire | ||

|

|

|

| Per well | Total | Per well |

| Total |

|

|

|

|

|

|

|

|

|

|

|

208 |

| 3 | 60 | 14400 | 28800 | 39.9 |

| 79.8 | 3+G |

240 |

| 3 | 60 | 14400 | 28800 | 37.2 |

| 74.4 | 3+G |

480 |

| 3 | 60 | 14400 | 28800 | 17.5 |

| 35.0 | 3+G |

Two electrical connections required, one for each well. Power cord and plug must be installed on site by a qualified electrician.

Gas models

120 | 1 | 60 | N/A | 12.0 | 24.0 | 2+G |

230 | 1 | 50 | N/A | 2.5 | 5.0 | 1NG |

Bidding Specifications

•Provide Henny Penny open fryers, models

•Units shall have

•Units shall incorporate either COMPUTRON™1000 simple digital controls or COMPUTRON™ 8000 control system with (additional charge.)

• | or manual operation with |

drain pan and various fittings are stainless | and LED digital display. COMPUTRON™ 8000 |

steel. Dump station is integral stainless steel. | control offers idle and melt modes, load |

Fry pots are heavy duty stainless steel. | compensation, filtration tracking and |

• Units shall incorporate | history. |

exchange design for extremely fast recovery. • | Units will include four |

• Units qualify for the ENERGY STAR® mark. | locking. |

•Heating elements encircle the fry pot part- • Units with filtration system ship with stainless

way up the side, and are not located at the | steel Max filtration screen and (2) PHT filter |

bottom or below the pot. This design | envelopes. All units ship with choice of (2) full |

produces a “cold zone” that extends oil life. | baskets, (1) full and (2) half baskets, or (4) half |

• Unit’s controller provides for programmable | baskets. |

Continuing product improvement may subject specifications to change without notice.

www.hennypenny.com

© 2006 Henny Penny Corporation, Eaton, OH 45320 USA Revised 09/10/08