PROJECT

ITEM NO

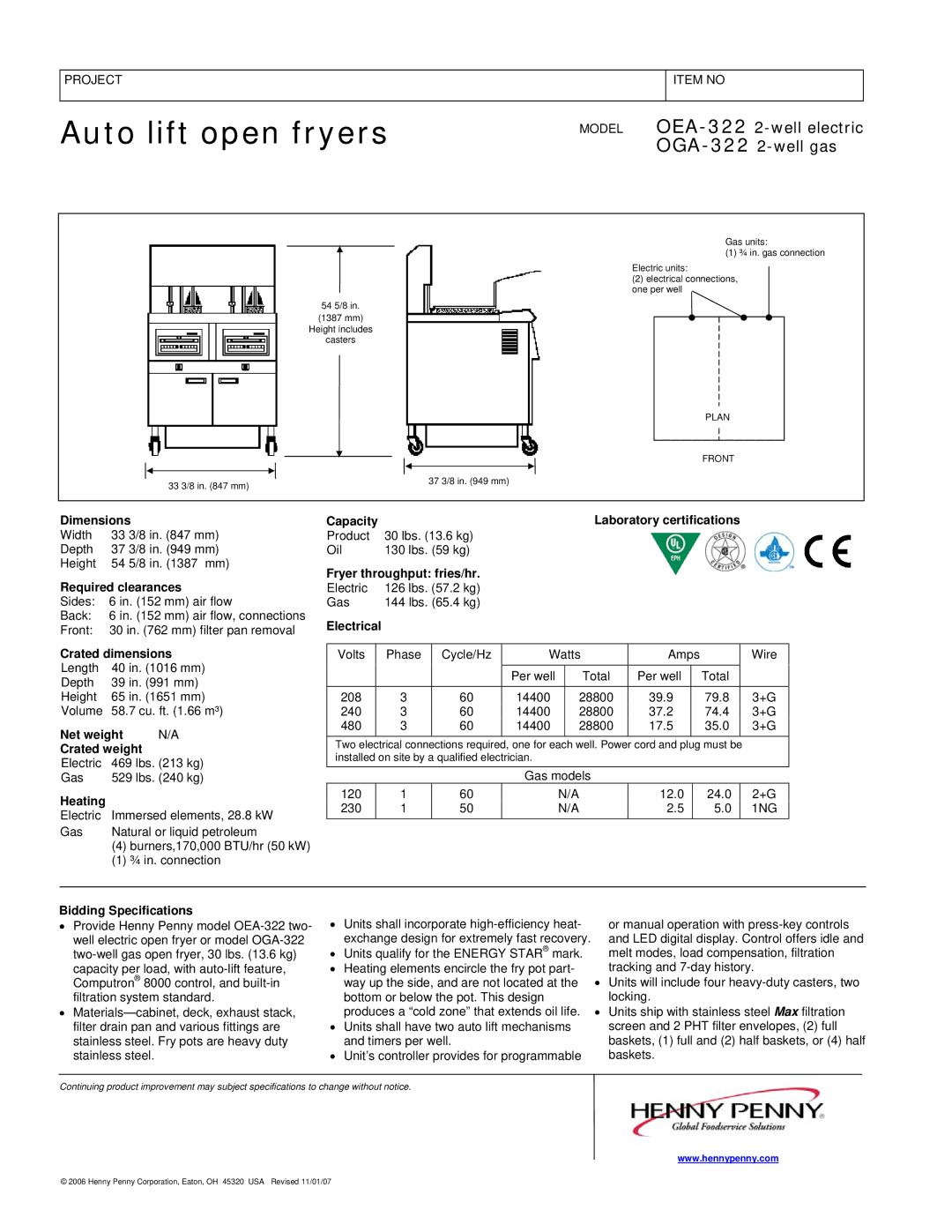

Auto lift open fryers

MODEL

Gas units:

(1) ¾ in. gas connection

Electric units:

(2) electrical connections, one per well

54 5/8 in.

(1387 mm)

Height includes

casters

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PLAN |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 37 3/8 in. (949 mm) |

|

|

|

|

|

|

| FRONT |

|

|

| |||

|

| 33 3/8 in. (847 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

Dimensions |

|

| Capacity |

|

|

|

|

|

|

| Laboratory certifications |

|

|

| ||||||||

Width | 33 3/8 in. (847 mm) | Product | 30 lbs. (13.6 kg) |

|

|

|

|

|

|

|

|

|

|

|

| |||||||

Depth | 37 3/8 in. (949 mm) | Oil | 130 lbs. (59 kg) |

|

|

|

|

|

|

|

|

|

|

|

| |||||||

Height | 54 5/8 in. (1387 mm) | Fryer throughput: fries/hr. |

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

Required clearances |

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||

Electric | 126 lbs. (57.2 kg) |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

Sides: | 6 in. (152 mm) air flow | Gas | 144 lbs. (65.4 kg) |

|

|

|

|

|

|

|

|

|

|

|

| |||||||

Back: | 6 in. (152 mm) air flow, connections | Electrical |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

Front: | 30 in. (762 mm) filter pan removal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

Crated dimensions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

Volts |

| Phase |

| Cycle/Hz |

| Watts |

| Amps |

|

| Wire |

|

| |||||||||

Length | 40 in. (1016 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

| Per well |

| Total | Per well |

| Total |

|

|

|

| ||||||

Depth | 39 in. (991 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

Height | 65 in. (1651 mm) | 208 |

| 3 |

| 60 |

| 14400 |

| 28800 | 39.9 |

|

| 79.8 |

| 3+G |

|

| ||||

Volume | 58.7 cu. ft. (1.66 m³) | 240 |

| 3 |

| 60 |

| 14400 |

| 28800 | 37.2 |

|

| 74.4 |

| 3+G |

|

| ||||

Net weight | N/A | 480 |

| 3 |

| 60 |

| 14400 |

| 28800 | 17.5 |

|

| 35.0 |

| 3+G |

|

| ||||

Two electrical connections required, one for each well. Power cord and plug must be |

|

|

| |||||||||||||||||||

Crated weight |

|

|

|

|

| |||||||||||||||||

Electric | 469 lbs. (213 kg) | installed on site by a qualified electrician. |

|

|

|

|

|

|

|

|

|

|

| |||||||||

Gas | 529 lbs. (240 kg) |

|

|

|

|

|

|

| Gas models |

|

|

|

|

|

|

|

|

| ||||

Heating |

|

|

| 120 |

| 1 |

| 60 |

|

| N/A | 12.0 |

|

| 24.0 |

| 2+G |

|

| |||

|

|

| 230 |

| 1 |

| 50 |

|

| N/A | 2.5 |

|

| 5.0 |

| 1NG |

|

| ||||

Electric | Immersed elements, 28.8 kW |

|

|

|

|

|

|

|

|

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

Gas | Natural or liquid petroleum |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

(4)burners,170,000 BTU/hr (50 kW)

(1)¾ in. connection

Bidding Specifications

•Provide Henny Penny model

•

•Units shall incorporate

•Units qualify for the ENERGY STAR® mark.

•Heating elements encircle the fry pot part- way up the side, and are not located at the bottom or below the pot. This design produces a “cold zone” that extends oil life.

•Units shall have two auto lift mechanisms and timers per well.

•Unit’s controller provides for programmable

or manual operation with

•Units will include four

•Units ship with stainless steel Max filtration screen and 2 PHT filter envelopes, (2) full baskets, (1) full and (2) half baskets, or (4) half baskets.

Continuing product improvement may subject specifications to change without notice.

www.hennypenny.com

© 2006 Henny Penny Corporation, Eaton, OH 45320 USA Revised 11/01/07