English

OPERATION

1. Mounting and dismounting of the bit

Tighten

Loosen

Ring Sleeve

Fig. 5

(1)Mounting the bit.

Insert a screwdriver bit etc. into the keyless drill chuck. Firmly grasp the ring and tighten the sleeve by turning it toward the right (in the clockwise direction as viewed from the front). (See Fig.5)

NOTE: If the sleeve becomes loose during operation, tighten it further.

The tightening force becomes stronger when the sleeve is tightened.

(2)Dismounting the bit.

Firmly grasp the ring and loosen the sleeve by turning it toward the left (in the counterclockwise direction as viewed from the front). (See Fig.5)

![]() CAUTION:

CAUTION:

When mounting a bit into the keyless chuck, tighten firmly. If the sleeve is not tight, the bit may slip or fall out, causing injury.

NOTE: Loosening stuck or hard to move sleeves.

Grasp the bit installed in the keyless chuck, in a vise or similar tool.

Set the cap position to

2.Confirm that the battery is mounted correctly.

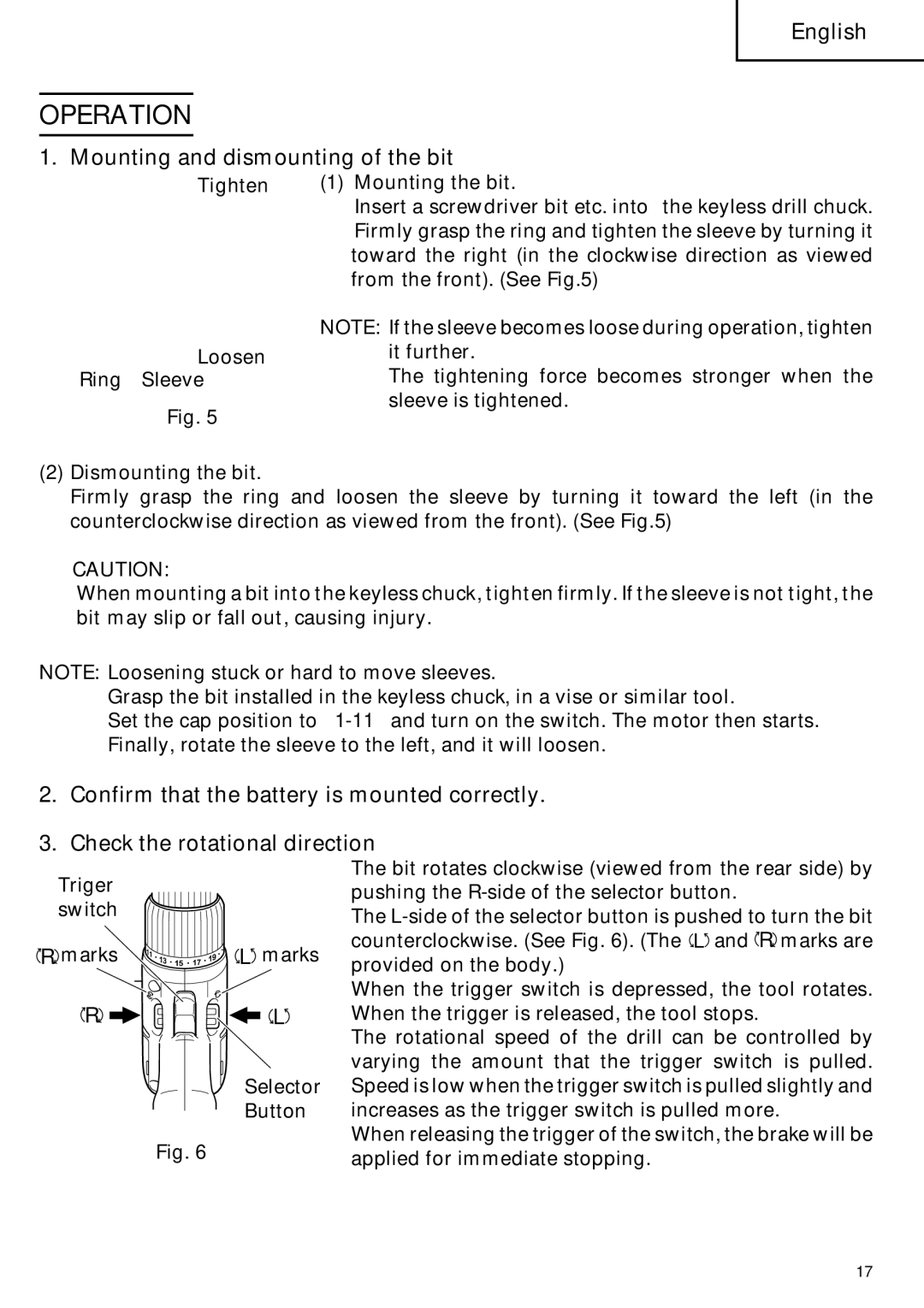

3.Check the rotational direction

The bit rotates clockwise (viewed from the rear side) by

Triger |

| pushing the | |

switch |

| ||

| The | ||

|

| ||

R marks | L marks | counterclockwise. (See Fig. 6). (The L and R marks are | |

provided on the body.) | |||

|

| ||

| ◯ When the trigger switch is depressed, the tool rotates. | ||

R | L | When the trigger is released, the tool stops. | |

| ◯ The rotational speed of the drill can be controlled by | ||

|

| varying the amount that the trigger switch is pulled. | |

| Selector | Speed is low when the trigger switch is pulled slightly and | |

| Button | increases as the trigger switch is pulled more. | |

| ◯ | When releasing the trigger of the switch, the brake will be | |

Fig. 6 | applied for immediate stopping. |

|

17