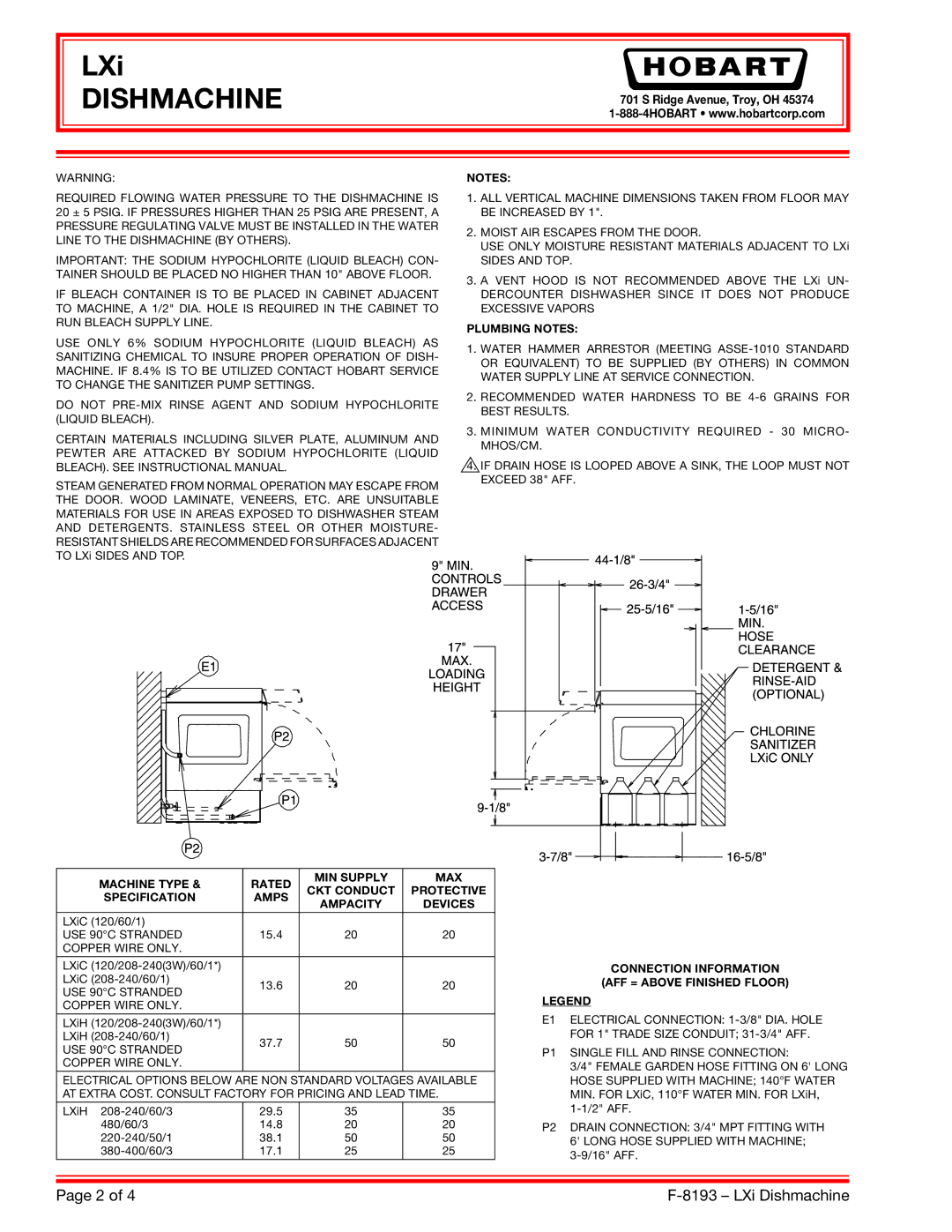

LXI specifications

The Hobart LXI is a cutting-edge commercial dishwasher that has garnered acclaim for its efficiency, sustainability, and advanced technology. Designed for high-volume kitchens, the LXI model combines robust performance with user-friendly features, making it a top choice for establishments such as restaurants, hotels, and catering services.One of the standout characteristics of the Hobart LXI is its impressive capacity. With the ability to process up to 25 racks per hour, it streamlines dishwashing operations, allowing kitchens to maintain productivity even during peak hours. The high throughput is achieved without compromising on cleaning quality, thanks to Hobart's unique triple-filter system, which ensures that dishes come out impeccably clean and sanitized.

Another significant feature of the LXI is its energy efficiency. The model is designed with sustainability in mind, consuming less water and energy compared to traditional dishwashers. It employs advanced recirculation technology that minimizes water waste while maximizing cleaning effectiveness. This not only reduces operational costs but also supports environmentally friendly practices in commercial kitchens.

The Hobart LXI is equipped with digital controls that simplify operation and monitoring. Users can easily set and adjust wash cycles based on the type and level of soiling, allowing for customization and flexibility. Additionally, the integrated soft-touch controls enable smooth navigation through various settings, making it accessible for all staff members, regardless of experience.

Durability is another hallmark of the LXI. Constructed with high-grade stainless steel, this dishwasher is built to withstand the rigors of daily use in busy kitchens. Its design also incorporates easy-to-clean surfaces and components, which help maintain hygiene and prolong the unit's lifespan.

Moreover, the LXI is designed with safety in mind. Features such as automatic door locks during the wash cycle and an intuitive warning system for low water levels contribute to user safety while enhancing operational reliability.

In conclusion, the Hobart LXI is an exceptional choice for commercial dishwashing solutions. Its high capacity, energy-efficient operation, advanced digital controls, and robust construction make it a reliable partner for any kitchen. With a focus on sustainability and user-friendly technology, the LXI stands out as a leader in modern commercial dishwashers.