1 |

|

|

|

2 | CV |

| CC |

INT. |

| EXT. | |

|

| ||

Front |

|

|

|

3 | 1 | 2 | 3 |

| 4 |

|

|

RC3

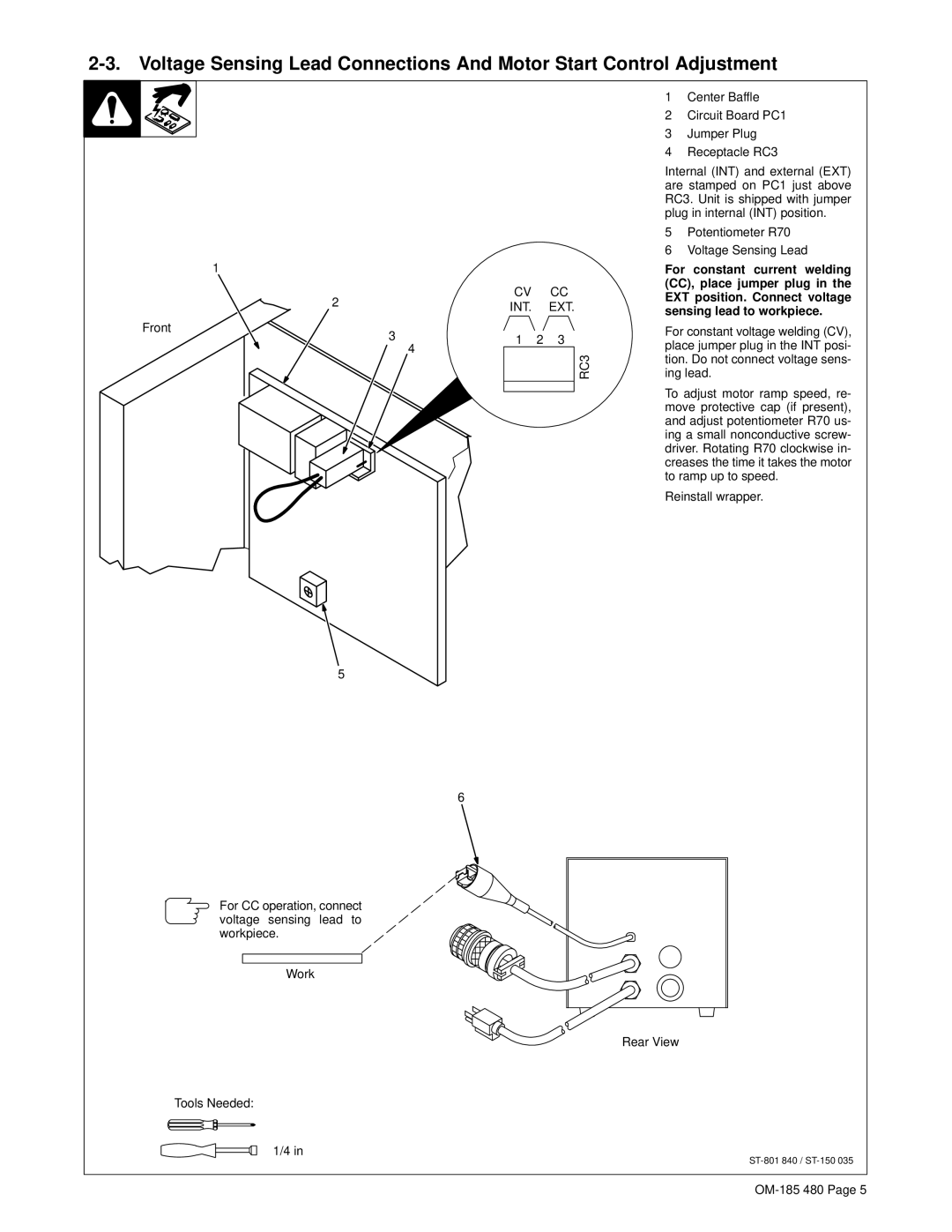

1Center Baffle

2Circuit Board PC1

3Jumper Plug

4Receptacle RC3

Internal (INT) and external (EXT) are stamped on PC1 just above RC3. Unit is shipped with jumper plug in internal (INT) position.

5Potentiometer R70

6Voltage Sensing Lead

For constant current welding (CC), place jumper plug in the EXT position. Connect voltage sensing lead to workpiece.

For constant voltage welding (CV), place jumper plug in the INT posi- tion. Do not connect voltage sens- ing lead.

To adjust motor ramp speed, re- move protective cap (if present), and adjust potentiometer R70 us- ing a small nonconductive screw- driver. Rotating R70 clockwise in- creases the time it takes the motor to ramp up to speed.

Reinstall wrapper.

5

6

For CC operation, connect voltage sensing lead to workpiece.

Work

Rear View

Tools Needed:

1/4 in