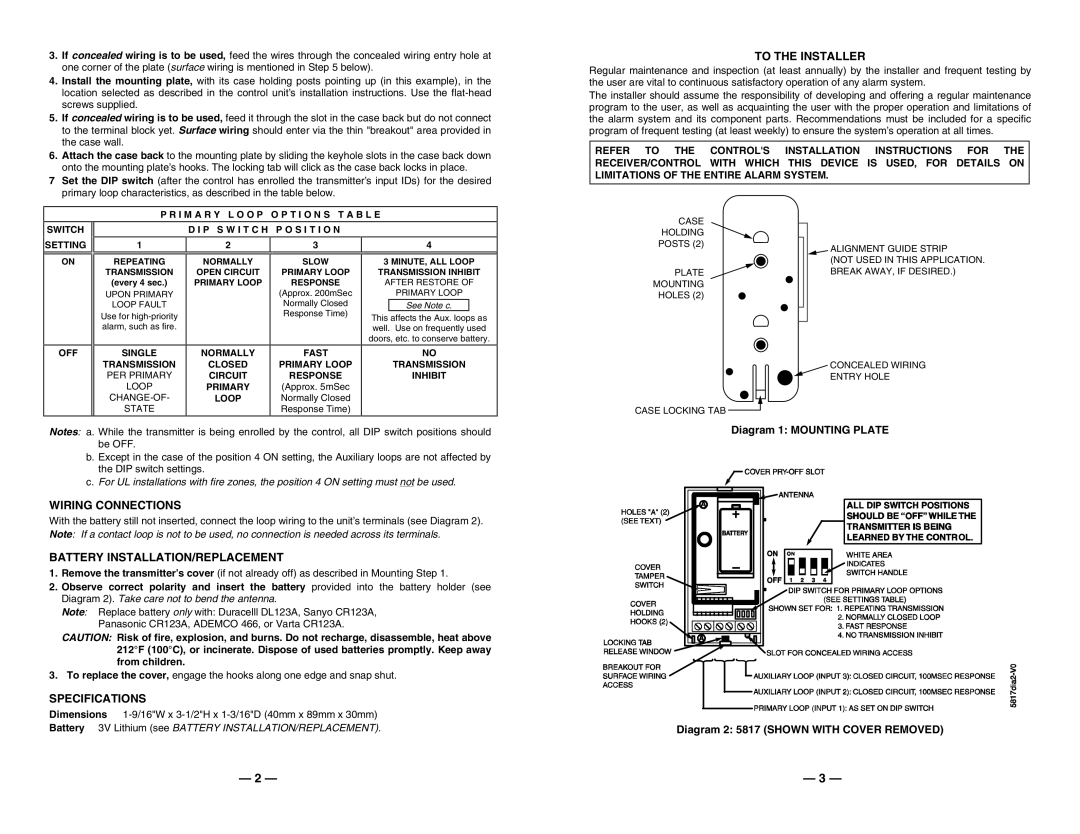

3.If concealed wiring is to be used, feed the wires through the concealed wiring entry hole at one corner of the plate (surface wiring is mentioned in Step 5 below).

4.Install the mounting plate, with its case holding posts pointing up (in this example), in the location selected as described in the control unit’s installation instructions. Use the

5.If concealed wiring is to be used, feed it through the slot in the case back but do not connect to the terminal block yet. Surface wiring should enter via the thin "breakout" area provided in the case wall.

6.Attach the case back to the mounting plate by sliding the keyhole slots in the case back down onto the mounting plate’s hooks. The locking tab will click as the case back locks in place.

7Set the DIP switch (after the control has enrolled the transmitter’s input IDs) for the desired primary loop characteristics, as described in the table below.

| P R I M A R Y L O O P O P T I O N S T A B L E | |

SWITCH |

| D I P S W I T C H P O S I T I O N |

TO THE INSTALLER

Regular maintenance and inspection (at least annually) by the installer and frequent testing by the user are vital to continuous satisfactory operation of any alarm system.

The installer should assume the responsibility of developing and offering a regular maintenance program to the user, as well as acquainting the user with the proper operation and limitations of the alarm system and its component parts. Recommendations must be included for a specific program of frequent testing (at least weekly) to ensure the system’s operation at all times.

REFER TO THE CONTROL'S INSTALLATION INSTRUCTIONS FOR THE RECEIVER/CONTROL WITH WHICH THIS DEVICE IS USED, FOR DETAILS ON LIMITATIONS OF THE ENTIRE ALARM SYSTEM.

CASE

HOLDING

SETTING

ON

1

REPEATING

TRANSMISSION

(every 4 sec.)

UPON PRIMARY

LOOP FAULT

Use for

2

NORMALLY

OPEN CIRCUIT PRIMARY LOOP

3

SLOW

PRIMARY LOOP

RESPONSE

(Approx. 200mSec

Normally Closed Response Time)

4

3 MINUTE, ALL LOOP

TRANSMISSION INHIBIT

AFTER RESTORE OF

PRIMARY LOOP

See Note c.

This affects the Aux. loops as well. Use on frequently used doors, etc. to conserve battery.

POSTS (2)

PLATE MOUNTING HOLES (2)

![]() ALIGNMENT GUIDE STRIP

ALIGNMENT GUIDE STRIP

(NOT USED IN THIS APPLICATION. BREAK AWAY, IF DESIRED.)

OFF | SINGLE | NORMALLY | FAST | NO |

| TRANSMISSION | CLOSED | PRIMARY LOOP | TRANSMISSION |

| PER PRIMARY | CIRCUIT | RESPONSE | INHIBIT |

| LOOP | PRIMARY | (Approx. 5mSec |

|

| LOOP | Normally Closed |

| |

| STATE |

| Response Time) |

|

CASE LOCKING TAB ![]()

CONCEALED WIRING ENTRY HOLE

Notes: a. While the transmitter is being enrolled by the control, all DIP switch positions should be OFF.

b. Except in the case of the position 4 ON setting, the Auxiliary loops are not affected by the DIP switch settings.

c.For UL installations with fire zones, the position 4 ON setting must not be used.

WIRING CONNECTIONS

With the battery still not inserted, connect the loop wiring to the unit’s terminals (see Diagram 2). Note: If a contact loop is not to be used, no connection is needed across its terminals.

BATTERY INSTALLATION/REPLACEMENT

1.Remove the transmitter’s cover (if not already off) as described in Mounting Step 1.

2.Observe correct polarity and insert the battery provided into the battery holder (see Diagram 2). Take care not to bend the antenna.

Note: Replace battery only with: Duracelll DL123A, Sanyo CR123A, Panasonic CR123A, ADEMCO 466, or Varta CR123A.

CAUTION: Risk of fire, explosion, and burns. Do not recharge, disassemble, heat above 212°F (100°C), or incinerate. Dispose of used batteries promptly. Keep away from children.

3.To replace the cover, engage the hooks along one edge and snap shut.

SPECIFICATIONS

Dimensions

Battery 3V Lithium (see BATTERY INSTALLATION/REPLACEMENT).

Diagram 1: MOUNTING PLATE

Diagram 2: 5817 (SHOWN WITH COVER REMOVED)

— 2 — | — 3 — |