DN 10DY specifications

The Honeywell DN 10DY is a state-of-the-art device designed to enhance automation and control in various industrial environments. Known for its robust features and advanced technology, this device is particularly renowned in sectors that require precision and reliability.One of the primary features of the DN 10DY is its high-performance data logging capabilities. This function enables users to monitor and record critical processes in real-time, ensuring that all necessary data is captured for analysis and reporting. It supports a wide range of data formats, allowing for seamless integration with existing systems.

In terms of communication technologies, the DN 10DY boasts multiple connectivity options, including Ethernet, MODBUS, and RS-232/RS-485 protocols. This versatility allows for easy integration into various types of networks, making it an adaptable choice for both new installations and upgrades of existing systems. The device also supports wireless communication options, ensuring flexibility in data transmission over various distances without the constraints of traditional cabling.

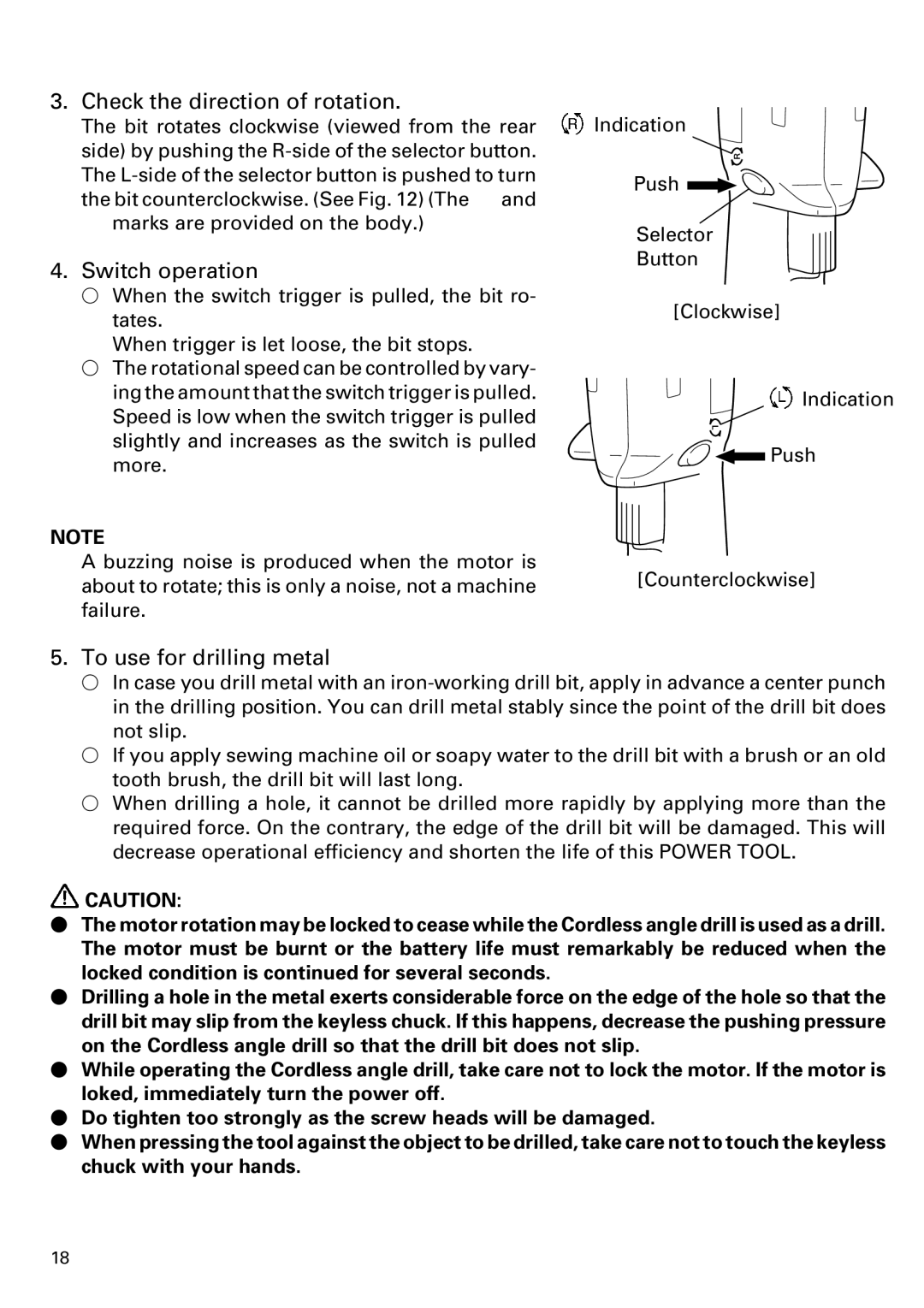

The DN 10DY utilizes advanced sensor technology to provide accurate and reliable measurements. Its sensors are designed to withstand harsh industrial conditions, such as extreme temperatures and humidity levels. This ensures that the device maintains optimal performance and longevity, even in challenging environments.

One of the standout characteristics of the Honeywell DN 10DY is its user-friendly interface. The device features a clear display that simplifies navigation and setup. Users can easily configure settings and monitor performance without extensive training, positioning the device as an excellent choice for operators at various experience levels.

Safety and compliance are paramount in industrial applications, and the DN 10DY meets various international standards, ensuring that users can rely on it for safe operations. Its built-in fail-safes and redundancy measures provide added security and peace of mind, reducing the risk of operational downtime due to equipment failures.

Overall, the Honeywell DN 10DY is a powerful tool for enhancing industrial automation and control. With its comprehensive features, robust communication technologies, and user-friendly design, it stands out as a reliable choice for businesses seeking to optimize their processes and improve operational efficiency.